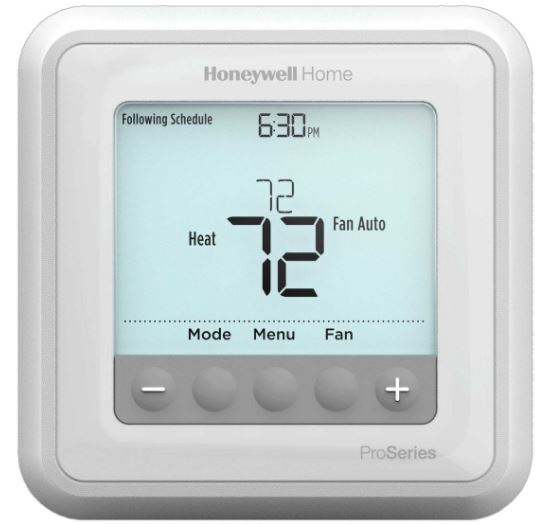

Honeywell T6 Pro Smart Thermostat

About Honeywell

Honeywell is a multinational conglomerate company that produces a variety of consumer and industrial products, including aircraft engines, automotive products, gas turbine power systems, and home appliances. The company also provides services such as energy management, building automation, and security systems. Honeywell was founded in 1906 and is headquartered in Charlotte, North Carolina.

Package Includes

- T6 Pro Thermostat

- UWP Mounting System

- Honeywell Standard Installation Adapter (J-box adapter)

- Honeywell Decorative Cover Plate – Small; size 4-49/64 in x 4-49/64 in x 11/32 in (121 mm x 121 mm x 9 mm)

- Screws and anchors

- 2 AA Batteries

- Installation Instructions and User Guide

Optional Cover Plate installation

NOTE: If Optional Cover Plate is not required, see “UWP Mounting System installation” on next page.

Use the Optional Cover Plate when:

- Mounting the thermostat to an electrical junction box

- Or when you need to cover paint gap from old thermostat.

- Separate the Junction Box Adapter from the Cover Plate. See Figure 1.

- Mount the Junction Box Adapter to the wall or an electrical box using any of the eight screw holes. Insert and tighten mounting screws supplied with Cover Plate Kit. Do not overtighten. See Figure 2. Make sure the Adapter Plate is level.

- Attach the UWP by hanging it on the top hook of the Junction Box Adapter and then snapping the bottom of the UWP in place. See Figure 3.

- Snap the Cover Plate onto the Junction Box Adapter. See Figure 4.

UWP Mounting System installation

- Before starting, turn the power off at the breaker box or switch. Open package to find the UWP. See Figure 5.

- Position the UWP on wall. Level and mark hole positions. See Figure 6. Drill holes at marked positions, and then lightly tap supplied wall anchors into the wall using a hammer. ‒ Drill 7/32” holes for drywall.

- Pull the door open and insert the wires through wiring hole of the UWP. See Figure 7.

- Place the UWP over the wall anchors. Insert and tighten mounting screws supplied with the UWP. Do not overtighten. Tighten until the UWP no longer moves. Close the door. See Figure 8.

Power options

Setting Slider Tabs

Set R Slider Tab.

- Use built-in jumper (R Slider Tab) to differentiate between one or two transformer systems.

- If there is only one R wire, and it is connected to the R, Rc, or RH terminal, set the slider to the up position (1 wire).

- If there is one wire connected to the R terminal and one wire connected to the Rc terminal, set the slider to the down position (2 wires).

NOTE:

Slider Tabs for U terminals should be left in place for T6 Pro models. Setting Slider Tabs

Wiring terminal designations

* Terminal can be jumped using Slider Tab. See “Setting Slider Tabs” above.

** The THP9045A1023 Wire Saver Module is used on heat/cool systems when you only have four wires at the thermostat, and you need a fifth wire for a common wire. Use the K terminal in place of the Y and G terminals on conventional or heat pump systems to provide control of the fan and the compressor through a single wire—the unused wire then becomes your common wire. See THP9045 instructions for more information.

Wiring conventional systems: forced air and hydronics

Shaded areas below apply only to TH6320U/TH6220U or as otherwise noted.

1H/1C System (1 transformer)

| R | Power [1] |

| Rc | [R+Rc joined by Slider Tab] [2] |

| Y | Compressor contactor |

| C | 24VAC common [3] |

| W | Heat relay |

| G | Fan relay |

Heat-only System

| R | Power [1] |

| Rc | [R+Rc joined by Slider Tab] [2] |

| C | 24VAC common [3] |

| W | Heat relay |

Heat-only System (Series 20) [5]

| R | Series 20 valve terminal “R” [1] |

| Rc | [R+Rc joined by Slider Tab] [2] |

| Y | Series 20 valve terminal “W” |

| C | 24VAC common [3] |

| W | Series 20 valve terminal “B” |

Heat-only System (power open zone valve) [5]

| R | Power [1] |

| Rc | [R+Rc joined by Slider Tab] [2] |

| W | Valve |

| C | 24VAC common [3] |

1H/1C System (2 transformers)

- R Power (heating transformer) [1]

- Rc Power (cooling transformer) [1]

- Y Compressor contactor

- C 24VAC common [3, 4]

| W | Heat relay |

| G | Fan relay |

Heat-only System with Fan

| R | Power [1] |

| Rc | [R+Rc joined by Slider Tab] [2] |

| C | 24VAC common [3] |

| W | Heat relay |

| G | Fan relay |

Cool-only System

| R | Power [1] |

| Rc | [R+Rc joined by Slider Tab] [2] |

| Y | Compressor contactor |

| C | 24VAC common [3] |

| G | Fan relay |

2H/2C System (1 transformer) [6]

| R | Power [1] |

| Rc | [R+Rc joined by Slider Tab] [2] |

| Y | Compressor contactor (stage 1) |

| C | 24VAC common [3] |

| W | Heat relay (stage 1) |

| G | Fan relay |

| W2 | Heat relay (stage 2) |

| Y2 | Compressor contactor (stage 2) |

NOTES

Wire specifications: Use 18- to 22-gauge thermostat wire. Shielded cable is not required.

- Power supply. Provide disconnect means and overload protection as required.

- Move R-Slider Tab on UWP to the R setting. For more information, see “Setting Slider Tabs” on page 3

- Optional 24VAC common connection.

- Common connection must come from cooling transformer.

- In ISU set Heat system type to Radiant Heat. Set number of cool stages to 0.

- In Installer Setup, set system type to 2Heat/2Cool Conventional.

Wiring heat pump systems

Shaded areas below apply only to TH6320U/TH6220U or as otherwise noted.

1H/1C Heat Pump System

| R | Power [1] |

| Rc | [R+Rc joined by Slider Tab] [2] |

| Y | Compressor contactor |

| C | 24VAC common [3] |

| O/B Changeover valve [7] | |

| G | Fan relay |

2H/1C Heat Pump System [8]

| R | Power [1] |

| Rc | [R+Rc joined by Slider Tab] [2] |

| Y | Compressor contactor |

| C | 24VAC common [3] |

| O/B Changeover valve [7] | |

| G | Fan relay |

| Aux Auxiliary heat | |

| E | Emergency heat relay |

| L | Heat pump fault input |

2H/2C Heat Pump System [9]

| R | Power [1] |

| Rc | [R+Rc joined by Slider Tab] [2] |

| Y | Compressor contactor (stage 1) |

| C | 24VAC common [3] |

| O/B Changeover valve [7] | |

| G | Fan relay |

| Y2 | Compressor contactor (stage 2) |

| L | Heat pump fault input |

3H/2C Heat Pump System (TH6320U only) [10]

| R | Power [1] |

| Rc | [R+Rc joined by Slider Tab] [2] |

| Y | Compressor contactor (stage 1) |

| C | 24VAC common [3] |

| O/B Changeover valve [7] | |

| G | Fan relay |

| Aux Auxiliary heat | |

| E | Emergency heat relay |

| Y2 | Compressor contactor (stage 2) |

| L | Heat pump fault input |

Dual Fuel System

| R | Power [1] |

| Rc | [R+Rc joined by Slider Tab] [2] |

| Y | Compressor contactor (stage 1) |

| C | 24VAC common [3] |

| O/B Changeover valve [7] | |

| G | Fan relay |

| Aux Auxiliary heat | |

| E | Emergency heat relay |

| Y2 | Compressor contactor (stage 2 – if needed) |

| L | Heat pump fault input |

| S | Outdoor sensor |

| S | Outdoor sensor |

NOTES

Wire specifications: Use 18- to 22-gauge thermostat wire. Shielded cable is not required

- Power supply. Provide disconnect means and overload protection as required.

- Move R-Slider Tab on UWP to the R setting. For more information, see “Setting Slider Tabs” on page 3

- Optional 24VAC common connection.

- In Installer Setup, set system type to 2Heat/2Cool Conventional.

- In Installer Setup, set changeover valve to O (for cool changeover) or B (for heat changeover).

- In ISU set Heat system type to Heat pump. 1 compressor and 1 stage of backup heat.

- In ISU set Heat system type to Heat pump. 2 compressors and 0 stage of backup heat.

- In ISU set Heat system type to Heat pump. 2 compressors and 1 stage of backup heat.

Thermostat mounting

- Push excess wire back into the wall opening.

- Close the UWP door. It should remain closed without bulging.

- Align the UWP with the thermostat, and push gently until the thermostat snaps in place.

- Turn the power on at the breaker box or switch.

System operation settings

- Press the Mode button to cycle to the next available System mode.

- Cycle through the modes until the required System mode is displayed and leave it to activate.

NOTE:

Available System modes vary by model and system settings.

System modes:

- Auto

- Heat

- Cool

- Em Heat

- Off

Fan operation settings

- Press the Fan button to cycle to the next available Fan mode.

- Cycle through the modes until the required Fan mode is displayed and leave it to activate.

NOTE:

Available Fan modes vary with system settings.

Fan modes:

- Auto: Fan runs only when the heating or cooling system is on.

- On: Fan is always on.

- Circ: Fan runs randomly about 33% of the time.

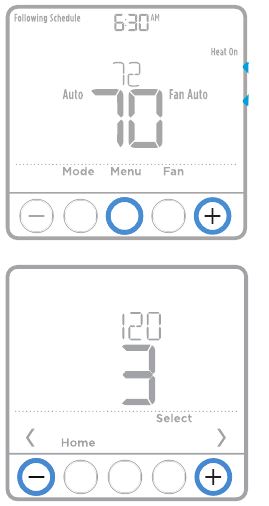

Installer setup (ISU)

- Press and hold CENTER and buttons for approximately 3 seconds to enter advanced menu.

- Press Select to enter ISU.

- Press Select to cycle through menu setup options.

- Press or to change values or select from available options.

- Press Select and confirm your settings or press Back to ignore changes and return to ISU menu screen to continue editing another setup option.

- To finish setup process and save your setting, press Home and return to Home screen.

NOTE:

A complete list of all setup (ISU) parameters and options starts below and continues through page 10.

Advanced setup options (ISU)

NOTE:

Depending on system settings, not all options may be available.

| # ISU | ISU Name | ISU Options (factory default in bold) |

| 120 | Scheduling Options | 0 = Non-Programmable 2 = 5-2 Programmable 3 = 5-1-1 Programmable 4 = 7-Day Programmable |

| 125 | Temperature Indication Scale | 0 = Fahrenheit 1 = Celsius |

| 130 | Outdoor Sensor (TH6320 / TH6220 only) |

0 = None 1 = Wired Outdoor Sensor |

| 200 | Heating System Type | 1 = Conventional Forced Air Heat 2 = Heat Pump 3 = Radiant Heat 5 = None (Cool Only) |

| 205 | Heating Equipment Type | Conventional Forced Air Heat: 1 = Standard Efficiency Gas Forced Air 2 = High Efficiency Gas Forced Air 3 = Oil Forced Air 4 = Electric Forced Air 5 = Hot Water Fan Coil Heat Pump: 7 = Air to Air Heat Pump 8 = Geothermal Heat Pump Radiant Heat: 9 = Hot Water Radiant Heat 12 = Steam |

| 218 | Reversing Valve O/B | 0 = O (O/B in Cool) 1 = B (O/B in Heat) |

| 220 | Cool Stages / Compressor Stages 200=Conv / 200=HP (TH6320 / TH6220 only*) |

0, 1, 2* |

| # ISU | ISU Name | ISU Options (factory default in bold) | |

| 221 | Heat Stages / Backup Heat Stages | Heat Stages: 1, 2 Backup Heat Stages: 0, 1 |

|

| 230 | Fan Control in Heat | 1 = Equipment Controls Fan 2 = Thermostat Controls Fan |

|

| 253 | Aux/E terminal control (TH6320 only) |

0 = Drive both Aux & E together 1 = Aux and E independent |

|

| 255 | Backup Heat Source (Heat Pump Only) |

1 = Electric Forced Air 2 = Gas/Oil Forced Air (or Fossil Forced Air) |

|

| 256 | Emergency Heat Source (TH6320 only) |

1 = Electric Forced Air 2 = Gas/Oil Forced Air (or Fossil Forced Air) |

|

| 260 | External Fossil Fuel Kit (TH6320 / TH6220 only) |

0 = Thermostat Controls Backup Heat 1 = External Fossil Fuel Kit Controls Backup Heat |

|

| 270 | Backup Heat Fan | 1 = Equipment Controls Fan 2 = Thermostat Controls Fan Note: Setting only active with TH6320 in Heat Pump mode. |

|

| 271 | Emergency Heat Fan | 1 = Equipment Controls Fan 2 = Thermostat Controls Fan Note: Setting only active with TH6320 in Heat Pump mode. |

|

| 300 | System Changeover | 0 = Manual 1 = Automatic |

|

| 303 | Auto Changeover Differential | 0 °F to 5 °F 0.0 °C to 2.5 °C Note: Differential is NOT deadband. Differential means how far past the setpoint before switching to the mode selected. Deadband setup is not an option. Honeywell uses an advanced algorithm that fixes deadband at 0 °F. This is more advanced than previous thermostats. |

|

| 340 | Backup Heat Droop | 0 = Comfort 2 = 2 °F 3 = 3 °F 4 = 4 °F 5 = 5 °F 6 = 6 °F 7 = 7 °F 8 = 8 °F |

9 = 9 °F 10 = 10 °F 11 = 11 °F 12 = 12 °F 13 = 13 °F 14 = 14 °F 15 = 15 °F |

| 350 | Upstage Timer for Backup Heat | 0 = Off 1 = 30 minutes 2 = 45 minutes 3 = 60 minutes 4 = 75 minutes 5 = 90 minutes 6 = 2 hours 7 = 3 hours 8 = 4 hours 10 = 5 hours |

|

| 355 | Compressor Lockout / Balance Point | — = Off 5 °F to 60 °F (in 5 °F increments) -15.0 °C to 15.5 °C (in 2.5 °C or 3.0 °C increments) Note: Use a wired sensor to set compressor lockout / balance point on TH6320 / TH6220. |

|

| 356 | Outdoor Lockout Backup Heat | — = Off 5 °F to 65 °F (in 5 °F increments) -15.0 °C to 18.5 °C (in 2.5 °C or 3.0 °C increments) |

|

| 365 | Compressor Cycle Rate (Stage 1) | 1 – 6 | |

| 366 | Compressor Cycle Rate (Stage 1) | 1 – 6 | |

| 370 | Heating Cycle Rate (Stage 1) | 1 – 12 | |

| 371 | Heating Cycle Rate (Stage 2) | 1 – 12 |

| # ISU | ISU Name | ISU Options (factory default in bold) | |

| 375 | Heating Cycle Rate Auxiliary Heat | 1 – 12 | |

| 378 | Heating Cycle Rate Emergency Heat (TH6320 only) |

1 – 12 | |

| 387 | Compressor Protection | 0 = Off 1 – 5 minutes |

|

| 425 | Adaptive Intelligent Recovery | 0 = No 1 = Yes Note: Adaptive Intelligent Recovery (AIR) is a comfort setting. Heating or cooling equipment will turn on earlier, ensuring the indoor temperature will match the setpoint at the scheduled time. |

|

| 430 | Minimum Cool Setpoint | 50 °F to 99 °F (50 °F) 10.0 °C to 37.0 °C (10.0 °C) |

|

| 431 | Maximum Heat Setpoint | 40 °F to 90 °F (90 °F) 4.5 °C to 32.0 °C (32.2 °C) |

|

| 435 | Keypad Lockout | 0 = None 1 = Partial 2 = Full |

|

| 500 | Is Indoor Temperature Sensor WIRED to your system? (TH6320 / TH6220 only) |

0 = No 1 = Yes |

|

| 515 | Indoor Sensor type (TH6320 / TH6220 only) |

0 = 10k 1 = 20k |

|

| 520 | Which Sensors will be used for TEMPERATURE Control? (Multiple Sensors are Averaged) (TH6320 / TH6220 only) |

1 = Thermostat Only 2 = Wired Only 3 = Average |

|

| 702 | Number of Air Filters | 0 – 2 | |

| 711 | Air Filter 1 Replacement Reminder | 0 = Off 1 = 10 Run Time Days 2 = 20 Run Time Days 3 = 30 Run Time Days 4 = 45 Run Time Days 5 = 60 Run Time Days 6 = 90 Run Time Days 7 = 120 Run Time Days 8 = 150 Run Time Days 9 = 30 Calendar Days |

10 = 45 Calendar Days 11 = 60 Calendar Days 12 = 75 Calendar Days 13 = 3 Calendar Months 14 = 4 Calendar Months 15 = 5 Calendar Months 16 = 6 Calendar Months 17 = 9 Calendar Months 18 = 12 Calendar Months 19 = 15 Calendar Months |

| 712 | Air Filter 2 Replacement Reminder | 0 = Off 1 = 10 Run Time Days 2 = 20 Run Time Days 3 = 30 Run Time Days 4 = 45 Run Time Days 5 = 60 Run Time Days 6= 90 Run Time Days 7 = 120 Run Time Days 8 = 150 Run Time Days 9 = 30 Calendar Days |

10 = 45 Calendar Days 11 = 60 Calendar Days 12 = 75 Calendar Days 13 = 3 Calendar Months 14 = 4 Calendar Months 15 = 5 Calendar Months 16 = 6 Calendar Months 17 = 9 Calendar Months 18 = 12 Calendar Months 19 = 15 Calendar Months |

| 1400 | Backlighting | 0 = On Demand 1 = Continuous Note: Common wire needed for continuous. |

|

| 1401 | Backlight brightness | 1 – 5 Note: Only displayed if continuous backlight selected. |

|

| 1410 | Clock Format | 12 / 24 | |

| 1415 | Daylight Saving Time | 0 = Off 1 = On |

|

| 1420 | Temperature Display Offset | -3 to 3F (0) -1.5 to 1.5C (0) |

Installer system test

To perform a System Test:

- Press and hold CENTER and buttons for approximately 3 seconds to enter advanced menu.

- Use to go to TEST. Press Select to enter System Test.

- Use to change between Heat, Cool, Fan, Em Heat, or Ver (thermostat version information). Press Select.

- Press to turn stages on one at a time, and press to turn them off.

- Use the Home button to exit the System Test.

| System test | System status | |

| Shaded areas below apply only to TH6320U/TH6220U or as otherwise noted. | ||

| Heat | 0 | All Off |

| 1 | Heat Stage 1 on | |

| 2 | Heat Stage 2 also on | |

| 3 | Heat Stage 3 also on | |

| Cool | 0 | All Off |

| 1 | Cool Stage 1 on | |

| 2 | Cool Stage 2 also on | |

| Em Heat | 0 | All Off |

| 1 | Em Heat on | |

| Fan | 0 | Fan Off |

| 1 | Fan On |

Specifications

- Temperature RangesHeat: 40 °F to 90 °F (4.5 °C to 32.0 °C)

Cool: 50 °F to 99 °F (10.0 °C to 37.0 °C) - Working Ambient Temperature

32 °F to 120 °F (0 C° to 48.9 °C) - Operating Ambient Temperature

37 °F to 102 °F (2.8 °C to 38.9 °C) - Shipping Temperature

-20 °F to 120 °F (-28.9 °C to 48.9 °C) - Operating Relative Humidity

5% to 90% (non-condensing) - Physical Dimensions in inches (mm) (H x W x D)

4-1/16” H x 4-1/16” W x 1-5/32” D

103.5 mm H x 103.5 mm W x 29 mm D

Electrical Ratings

| Terminal | Voltage (50/60Hz) |

Running Current |

| W Heating | 20-30 Vac | 0.02-1.0 A |

| (Powerpile) | 750 mV DC | 100 mA DC |

| W2 (Aux) Heating | 20-30 Vac | 0.02-1.0 A |

| E Emergency Heat | 20-30 Vac | 0.02-0.5 A |

| Y Compressor Stage 1 | 20-30 Vac | 0.02-1.0 A |

| Y2 Compressor Stage 2 | 20-30 Vac | 0.02-1.0 A |

| G Fan | 20-30 Vac | 0.02-0.5 A |

| O/B Changeover | 20-30 Vac | 0.02-0.5 A |

| L/A Input | 20-30 Vac | 0.02-0.5 A |

CAUTION: MERCURY NOTICE

If this product is replacing a control that contains mercury in a sealed tube, do not place the old control in the trash. Contact your local waste management authority for instructions regarding recycling and proper disposal.

CAUTION: EQUIPMENT DAMAGE HAZARD

Compressor protection is bypassed during testing. To prevent equipment damage, avoid cycling the compressor quickly.

CAUTION: ELECTRICAL HAZARD

Can cause electrical shock or equipment damage. Disconnect power before beginning installation.

Customer assistance

For assistance with this product, please visit customer.honeywell.com.

Or call Honeywell Customer Care toll-free at 1-800-468-1502.

Customer assistance

Pull to remove the thermostat from the UWP.

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® U.S. Registered Trademark.

© 2016 Honeywell International Inc.

33-00181EFS—01 M.S. 06-16

Printed in U.S.A.

FAQs for Honeywell T6 Pro Installation Instructions Manual

Has auto changeover been added to the Honeywell t6 Pro?

The thermostats made by Lyric T6 Pro have auto-changeover. As a result, depending on the ambient temperature and the heating and cooling set points, the thermostat can switch between heating and cooling as needed. Your thermostat has not been set up for automatic changeover if “auto” is not listed as an option.

Has the Honeywell t6 Pro WiFi?

Your T6 Pro Smart Thermostat can interface with smart home systems like Apple HomeKit and Amazon Echo when it is connected to your existing WiFi, enabling you to change the temperature as easily as you would a song on your playlist. The phases of your heating system, up to 2 Heat/1 Cool with a heat pump, are likewise compatible with this WiFi thermostat.

How can a Honeywell T6 be placed on indefinite hold?

Adjust the temperature setting on your thermostat’s display to “Permanent Hold.” The following schedule change’s time will display after a “HOLD UNTIL” notification. When you tap the HOLD UNTIL message, the messages PERMANENT HOLD and RUN SCHEDULE will also appear. To maintain the new setting permanently, press PERMANENT HOLD.

Can the Honeywell T6 show humidity?

A system’s status You can show the current temperature, the relative humidity in percent, or if your heating or cooling system is on.

Honeywell Pro Series is high voltage, right?

Both low voltage (24 volts) and line voltage (120 or 240 volts) systems can use Honeywell thermostats. 24 volts is the most typical voltage from a central heating and/or cooling system (24Vac).

Is the Honeywell T6 battery operated?

Both a hardwired connection and two AA batteries can power the T6 Pro.

Do you need C wire for the Honeywell T6 Pro?

The common wire, commonly referred to as a “C” wire, is necessary for the T5/T6 pro Wi-Fi thermostats. The thermostat can run without batteries thanks to the “C” or common wire. It must be linked to the furnace control board’s common connection, marked C.

Honeywell: Does it function without wifi?

Yes, even if your Wi-Fi network is down, the thermostat will still control your heating and/or cooling system.

My Honeywell t6 has an auto mode, how do I activate it?

1 On the thermostat’s home screen, tap Mode until Auto appears. Next, tap or to select your chosen temperature setting for the presently selected mode (heating or cooling). 2 To transition to the inactive mode, next touch the text area where the active mode is visible.

Can I use my phone to operate my Honeywell thermostat?

You can program your thermostat from a computer, tablet, or smartphone, whether you’re nearby or halfway over the world, thanks to Honeywell’s dependable and highly regarded app.

How do I adjust my Honeywell thermostat?

Setting the temperature on your Honeywell thermostat is easy if you have a manual thermostat. To adjust the temperature, simply push the up and down buttons. Until you adjust it again, the temperature you set will remain.

Pdf – Honeywell T6 Pro Installation Instructions Manual

For More Posts Visit: ManualsDock