![]()

SAFETECH Dock Leveller

About SafeTech

SAFETECH offers a comprehensive range of services and personal protective equipment to all businesses that require workers to be at heights. The heart of the SAFETECH team is Mr. Sudipto Bose, a self-driven businessman who founded SAFETECH on his own with the goal of REDEFINING HEIGHT SAFETY STANDARDS.

Overview

Why choose the Safetech Dock Leveller?

The only Australian designed dock leveller built tough to suit Australian conditions

- Designed to AS3990, AS3000 and ANSI MH-30.9-2007.

- Extensive load bearing cycle testing conducted to prove design longevity.

- Design confi rmed through the latest computer generated fi nite element analysis.

- Deck features narrowly spaced support beams (max 200mm) for superior structural integrity.

- High tensile reinforced anti-slip steel checker plate load lip offers added strength and the smoothest transition between chamfered lip edge and trailer floor.

The Australian market leader for more than 40 years

Used and proven by all major Australian retailers, transport and logistics companies. constant improvements have been made to keep our dock levellers ahead of the rest. These include:

- Upgrading the mechanical operating system to hydraulic/electric.

- Reversing the operation of the deck cylinder to minimise wear on the rear welds.

- Various safety mechanisms including the improved one man operation maintenance prop, velocity fuse system and low voltage controls to prevent electric shock.

Features

STRUCTURAL STRENGTH

- Designed to AS4100, AS0418/8 and AMSI MH-30-2007.

- Extensive load bearing cycle testing to prove design longevity.

- Simple and proven geometry. Designed to accommodate truck beds canted up to 100mm.

FULLY ENCLOSED HINGE DESIGN

- Pieces of broken pallet or other waste cannot jam in the hinge, maintaining smooth unrestricted operation.

- Reduces product damage.

- Rear Hinge provides a seamless and soft transition between the warehouse fl oor and dock leveller.

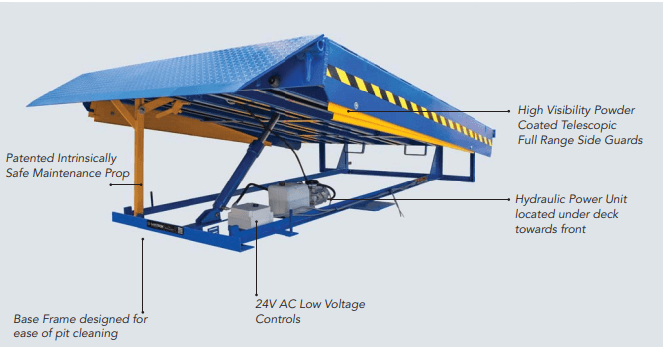

HYDRAULICS

- Deck floats on hydraulics. Adjusts to match trailer height during loading or unloading.

- Smooth and quiet hydraulic power unit located under dock.

MOUNTING OPTIONS

Safety

MAINTENANCE PROP – INTRINSICALLY SAFE

- Engaged and disengaged by a single person from the upper dock level without needing to reach under the Dock Leveller.

- Stays in place if the deck is accidentally impacted.

- Provides a lockout facility with visual confi rmation.

- Securely supports both the deck and lip for safe servicing.

- Reduced servicing costs (only need 1 person to service). Most other designs require servicing by 2 persons.

FORWARD MOUNTED COMPONENTS

- Reduces technician fatigue by bringing all components within arms reach.

- Allows ease of access for maintenance, cleaning or repair.

- Removal of unnecessary cabling and other components.

- No need to enter the often dirty, unsanitary, confi ned space for simple servicing and periodical inspection.

DURADOCKTM – 2 PART COMPOSITE DOCK BUMPERS

- Long lasting high impact protection for docks and trucks.

- Superior low friction contact surface .

- Revolutionary design with shock absorbing backing material.

- Lighweight, can be easily retrofi tted to existing docks.

- Specification: 250W x 460H x 100D Weight: 9.0 kg each.

OPERATION

- Constant pressure button. This prevents accidental injury to personnel or damage to surrounding objects.

- Small enclosure (70W x 70L x 50D) mounted on wall giving more room for other services on an often crowded internal dock wall.

- Low voltage control minimises the risk of electrical shock and ease of interlocking with all types of dock door systems.

Operation

The Safetech Dock Leveller can be operated by just 1 button. (2 button independent lip controls optional)

TO ENGAGE THE DOCK LEVELLER

Push and hold the button

- Deck raises

- The Load Lip will then fold out

Release the button

- Deck lowers onto the truck bed with the Load Lip extended.

LOADING AND UNLOADING

- Once engaged, loading and unloading can occur.

- Dock Leveller deck will float up and down with the truck.

TO STOW THE DOCK LEVELLER

Push and hold the button

- The deck will raise until the Lip has retracted.

Specifications

COMPONENTS

- Power

Unit 1.1kW / 415V / 3 Phase / 10A / 50 Hertz - Power Requirement

415V / 3 Phase / 10 Amp 4 Pin Switched Outlet Protected by a D Curve circuit breaker - Controls

Low voltage 24V AC wall mounted controls - Side Guards

Full Range Hi Visibility Telescopic Side Protection

Powder Coated for durability - Product Finish

Blue Industrial Spray Enamel

Leveller Structure primed with anti-rust undercoat

Options

HYDRAULIC DOCK LEVELLER CAPACITY

To assess the required capacity, all Safetech Dock Levellers have a rated static capacity, which is measured when the Dock Leveller is stowed. Safetech Dock Levellers are market leaders in their safe operating dynamic load capacities, which is approximately 65% of the rated static capacity. These measurements assume that any forklift or loader does not exceed 5km/hr and the operating grade does not exceed 10%.

For conditions which exceed these standards, please contact Safetech for your individual requirements.

* Higher capacity levellers available based on gross fork / load weights, servicing gradients, speed and usage frequency

OPTIONS

- Independent Lip Control Dual push button panel – “Dock Raise” and “Lip Raise”

- Custom Sizes For replacements and where spatial issues exist

- Seal Strips Brush or rubber side pit seals for environmental and vermin control

- Single Phase Power Pack Phase / 240V / 50 Hertz power unit available

- Modified Base Frame To suit deep or shallow pit installations

- Heavy Duty Models For Heavy Duty applications (e.g Paper Industry). Contact Safetech to discuss

- Steel Faced Dock Bumpers DuraDock™ Steel faced bumpers for extra strength, durability and protection.

- Custom Finishes For corrosive environments, hot dipped galvanised & marine grade non slip surfaces

- Self Supporting Pitless frames

- Interlocking Dock door interlocking provision standard

- Controls Panels Integrated control panels for sequencing with other dock equipment

Further information

Contact your local Safetech sales representative for a copy of our Dock Products, Palift or Lift Tables brochures.

DOCK PRODUCTS BROCHURE

For more information about our full range of Dock Products, including popular items such as:

- Shelters

- Seals

- Wheel and Trailer Restraints

- Pit Box’s

- Control Panels

- plus much more.

Head office 39-45 Della Torre Road

Moe Victoria 3825

t: 1800 674 566

e: sales@safetech.com.au

- National offices Victoria/South Australia 03 8546 5600

- New South Wales/ACT 02 9725 2699

- Queensland/NT 07 3267 0483

- Western Australia 08 6140 6644

- Authorised agents Tasmania 03 6335 9500

- New Zealand 0800 40 40 60

FAQ’s SAFETECH Dock Leveller

Need electricity for hydraulic dock levellers?

The drawbacks of hydraulic dock levellers include the fact that, in contrast to mechanical dock levellers, they use power and are substantially more expensive to buy and instal.

What is the weight of levellers?

Weighing between 1,225 pounds (6′ x 6′ dock leveller) and 1,650 pounds (7′ x 8′ dock leveller), our mechanical dock levellers have the same weight capacity (27,000 pounds) but are lighter.

A dock leveller can support how much weight?

Dock levellers typically have capacities ranging from 25,000 to 80,000 pounds. In this capacity range, dock leveller installations make up more than 90% of the total.

How durable are dock levellers?

Hydraulic dock levellers must also be replaced since the motors deteriorate and the welds crack, especially if they are operated past their 10-year life expectancy and/or beyond their capacity. Keep in mind that over time, this equipment can suffer serious damage, necessitating replacement at some point.

What makes dock levellers so crucial?

A dock leveller is one component that has grown significantly in importance, primarily because it is essential for loading and unloading trailers and trucks. Most notably, dock levellers work to lower the likelihood of mishaps.

How often does a dock leveller need maintenance?

To check for proper operation and any potential risks, the Dock Leveller should be run through at least one complete cycle. Exams must be performed at least once a year.

What is the time required to instal a dock leveller?

In just one day, a new dock leveller may be fitted.

Just how precise is a leveller?

The vials in a spirit level typically have a yellowish-green hue and additives for UV protection and optimum operation in temperatures between -20 and 130 degrees Fahrenheit. The most accurate spirit level is accurate to +/- 0.5 millimeters/meter, 0.005 inches/inch, or. 029 degrees.

How far can floor levellers be used?

Installers can choose between QUIKRETE® Self-Leveling Floor Resurfacer (No. 1249-50) thicknesses of 5/8 inch (16 mm) and a feather edge. Apply QUIKRETE® Self-Leveling Floor Resurfacer (No. 1249-50) in layers no thicker than 5/8 inch (16 mm) apiece for areas deeper than that.

What thickness is ideal for levellers?

Many levelling compounds only recommend a minimum thickness of 2 or 3 millimetres (some require a minimum of 5mm).