Carrier EB-STATE3LTCR-01 ecobee3 lite Pro Smart Thermostat

Safety Considerations

Read and follow manufacturer instructions carefully. Follow all local electrical codes during installation. All wiring must conform to local and national electrical codes. Improper wiring or installation may damage the Thermostat. Recognize safety information. This is the safety alert symbol. When you see this symbol on the equipment and in the instruction manual, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, and CAUTION. These words are used with the safety-alert symbol. DANGER identifies the most serious hazards which will result in severe personal injury or death. WARNING signifies a hazard that could result in personal injury or death.

CAUTION is used to identify unsafe practices which may result in minor personal injury or product and property damage. NOTE is used to highlight suggestions that will result in enhanced installation, reliability, or operation.

Introduction

The ecobee Smart Thermostat Pro with voice control, Powered by ventilator, HRV, or ERV. When used with a boiler they cannot be installed with the PEK if a C wire isn’t present, the C wire must come from the air handler, not the boiler. Carrier and the ecobee3 lite Pro, Powered by Carrier provides your customers with freedom and flexibility to manage their home environment. These thermostats help homeowners conserve energy, save money, and reduce their environmental impact.

They support a furnace with AC and up to 2-stages of heat. For heat pumps (air to air or Geothermal) they support up to four stages of heat (2-stage heat pump, 2-stage auxiliary heat) and two stages of cool. For these systems, the thermostats can control a single accessory, such as a humidifier, dehumidifier, ventilator, HRV, or ERV. Also, the thermostats can be installed with the PEK if a C wire isn’t present. Additionally, the thermostats can control boilers with or without an AC. When connected to a boiler, the thermostats support up to 2-stage of heat and 2-stages of cooling and a single accessory, such as a humidifier, or dehumidifier.

How to use this document

The advanced installation and configuration instructions are intended to supplement the standard installation instructions shipped with the thermostat or are available for download on www.HVACpartners.com. The advanced settings and configuration options detailed in this document are intended for professional installers only. Incorrect configuration may lead to improper operation and equipment damage.

Each section of this document is outlined in the following structure:

Section Title

Location of this section within the thermostat menus. Image showing available features in this section on the thermostat.

Feature Title

- Feature Description

- Default Configuration

- Configuration Options

WARNING

ELECTRICAL OPERATION HAZARD Failure to follow this warning could result in personal injury or death. Before installing, modifying, or servicing the system, the main electrical disconnect switch must be in the off position. There may be more than 1 disconnect switch. Lock out and tag the switch with a suitable warning label.

CAUTION

ELECTRICAL OPERATION HAZARD Failure to follow this caution may result in equipment damage or improper operation. Improper wiring or installation may damage the thermostat. Check to make sure the wiring is connected before proceeding with installation or turning on the unit.

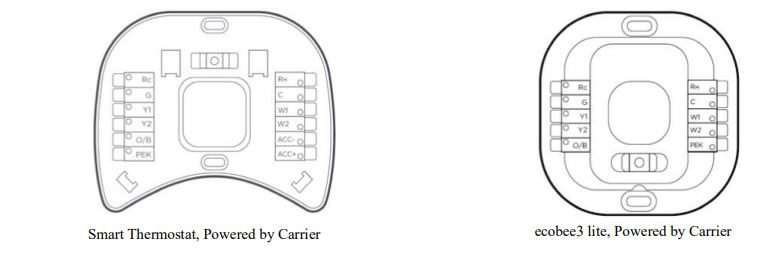

Hardware Differences

Print Label

Print Label

Reference the print label on the back of your ecobee device to identify the final assembly number, model name, country of origin, and device serial number.

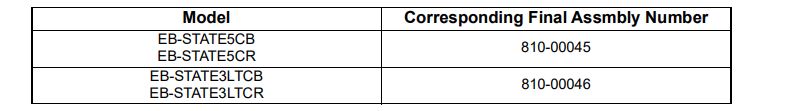

The following final assembly numbers and corresponding model names are as follows:

Table 1 – Final Assembly Number

Wiring Diagrams

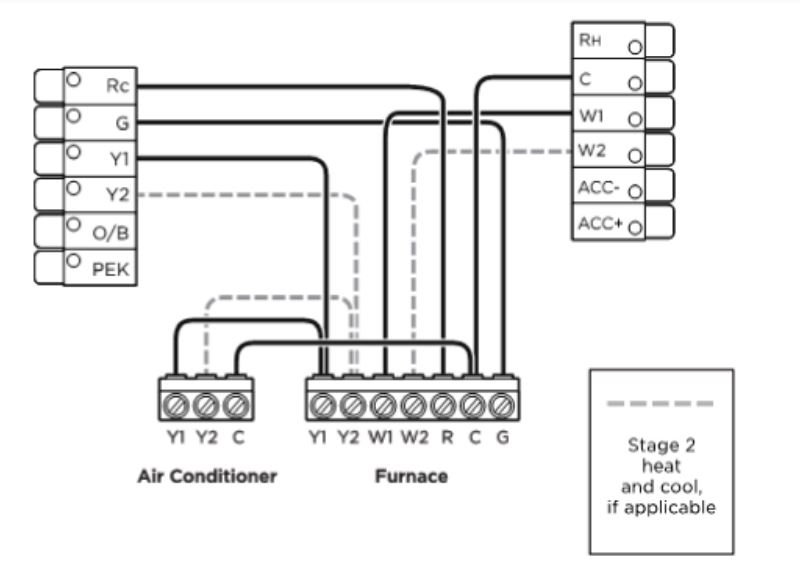

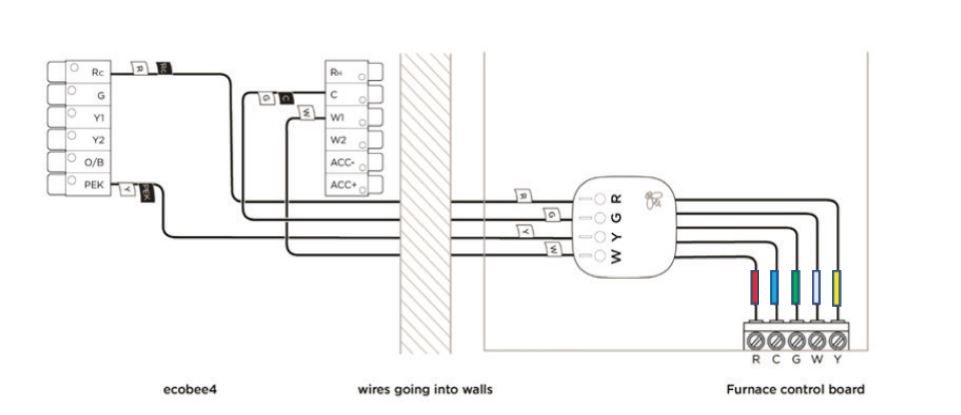

Conventional System

For single-stage heat and single-stage cooling applications, 5 wires are required instead of the traditional 4.

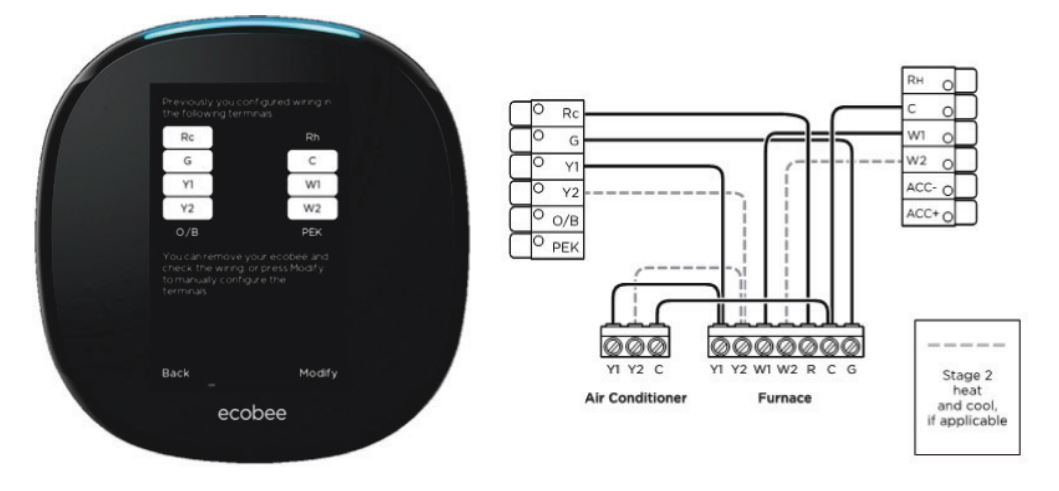

A common wire to power is needed to power the thermostat. Additional wires are shown as dotted lines for 2-stage equipment. Most Carrier 2-stage furnace equipment can be operated with a single-stage thermostat using the algorithm in the furnace circuit board to engage the 2nd stage.

While a 2-stage thermostat can control the equipment, it is preferred to allow the Carrier equipment to determine the staging by not connecting W2. See furnace installation instructions for heat staging setup.

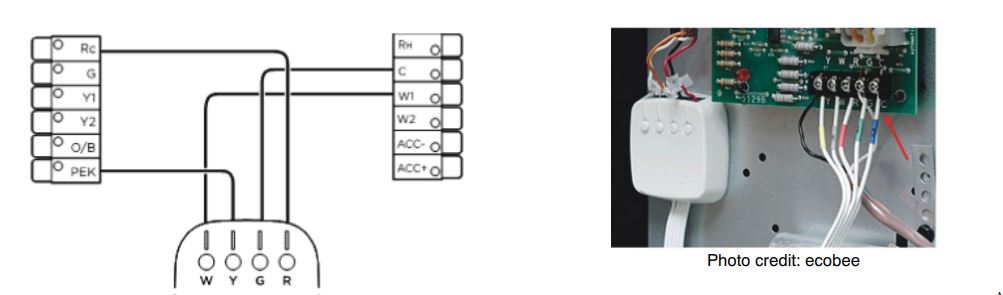

Power Extender Kit (PEK)

The Power Extender Kit, also known as the PEK, allows the thermostat to operate with 4 wires instead of 5, which helps with retrofit applications. The thermostat has a PEK terminal which digitally combines the G and Y1 signal.

The PEK device, which gets installed at the equipment, separates that combined signal back into separate 24v wires. The PEK can go from 5 to 6 wires or from 8 to 9 wires. It can always add one more wire to the available wires. The 4 wires at the thermostat should be wired as shown above. Additional wires would bypass the PEK and connect directly to the equipment.

Power Extender Kit (PEK)

In the example above, the PEK is shown with wire labels. The Red wire goes to Rc and the White wire goes to W. However, the Green wire, which is labeled G in the drawing does not go to G. Instead it becomes the common wire. The Yellow wire, labeled Y, goes to the PEK terminal.

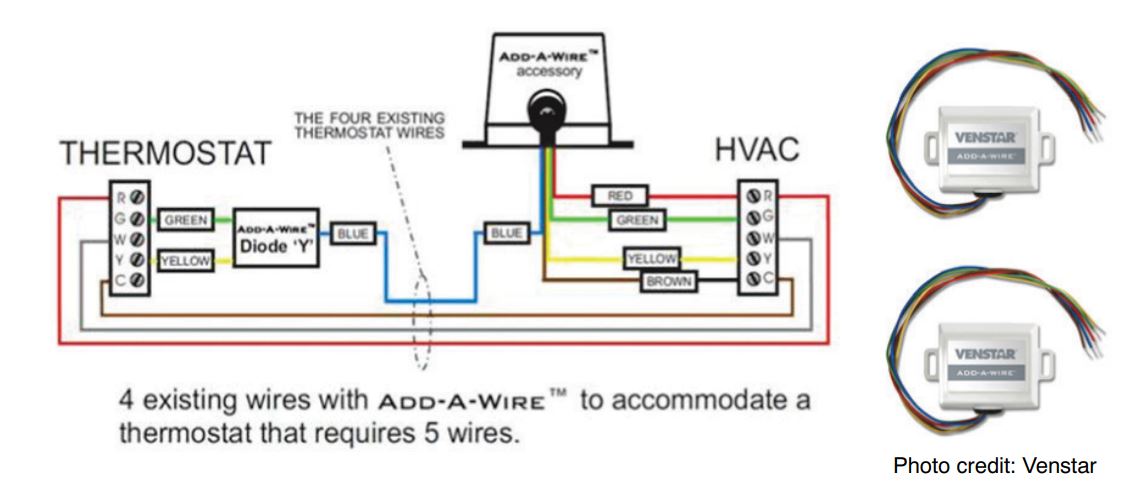

Add-A-Wire Kit

The Venstar Add-a-Wire Kit works similarly to the PEK. Normally this would not be needed because the PEK comes with the ecobee. However, the PEK is limited to one extra wire and only one PEK can be used per system. Several Add-a-Wire Kits can be used if needed. Each wire in the wall can be split using the diode to take care of two terminals on the thermostat. The only rule is that R and C cannot be split.

For example, if 6 wires are needed and only 4 wires are in the wall and you need 6, two kits could accomplish it. A Fast-Stat Wiring Extender can be used instead of an Add-a-Wire. The Honeywell Wiresaver cannot be used since it has a proprietary language and only works with certain Honeywell thermostats.

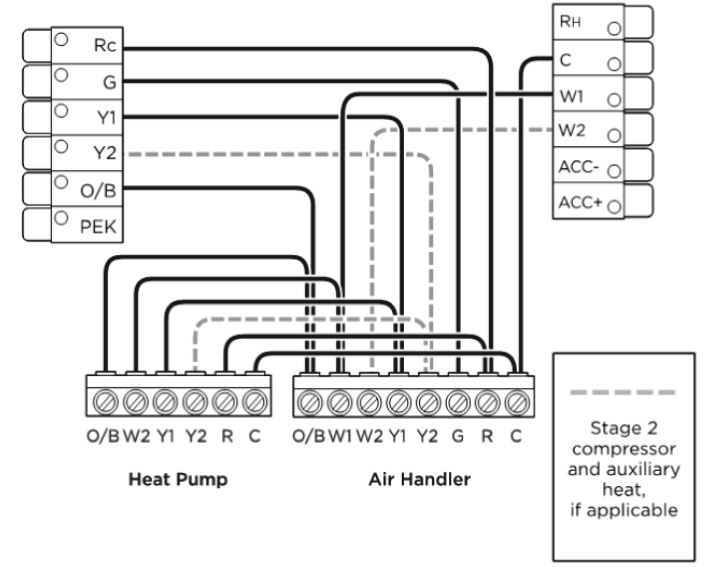

Heat Pump With Auxiliary Heat

For a traditional heat pump, Y1 is the compressor and O/B is the reversing valve. During the startup process, the O/B should be configured to act as an O terminal with Carrier equipment, since the equipment defaults to heating and needs the reversing valve to be energized on a cooling call. W1 is used for the auxiliary heat – typically, electric resistance.

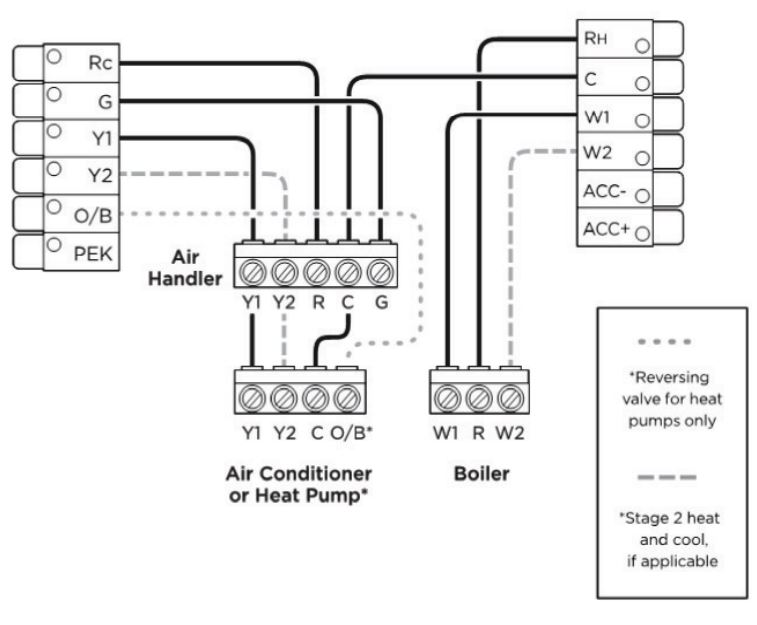

Boiler with Fan Coil

The ecobee thermostat can control two pieces of equipment where each has its transformer, such as a fan coil with a boiler. Both Rc and Rh are needed in this application.

Boiler-Only System

A boiler-only system still needs a common. The best solution is to run a 3rd wire to the boiler and tie it into the common. Many boilers will only have T-T terminals and not have a common terminal. In these cases, the common can be picked up directly from the transformer.

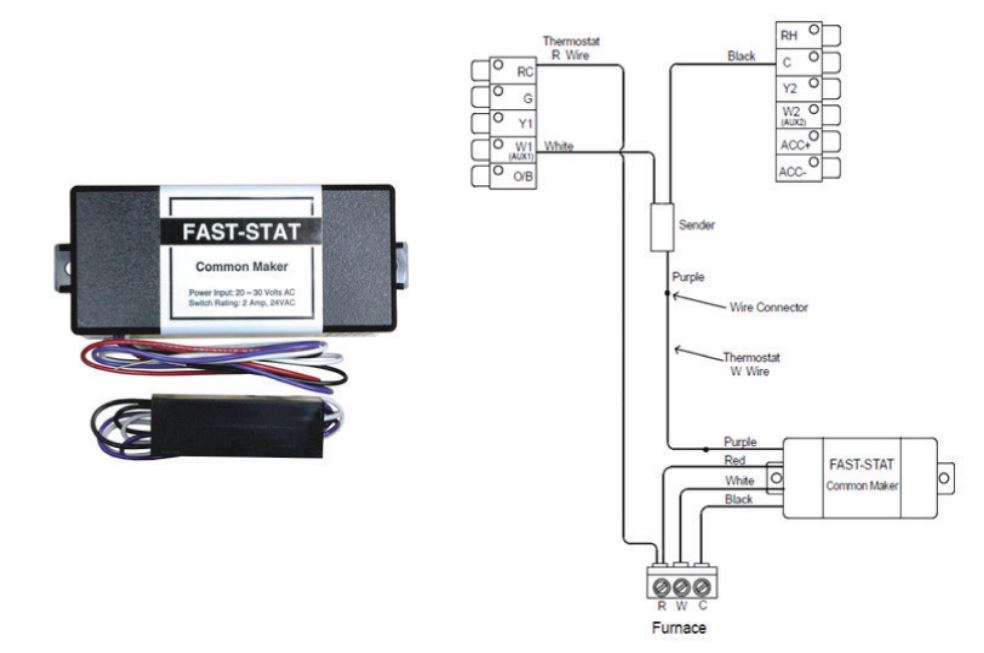

If it is not possible to run a wire, Fast-Stat makes a different accessory called a Common Maker that can be used. The ecobee PEK, Venstar Add-a-Wire, or Fast-Stat Wiring Extender accessories mentioned above cannot be used. The W call gets piggy-backed on the common wire with the small black sender module installed at the thermostat. Then the Common Maker is installed at the boiler where it separates the W signal from the common.

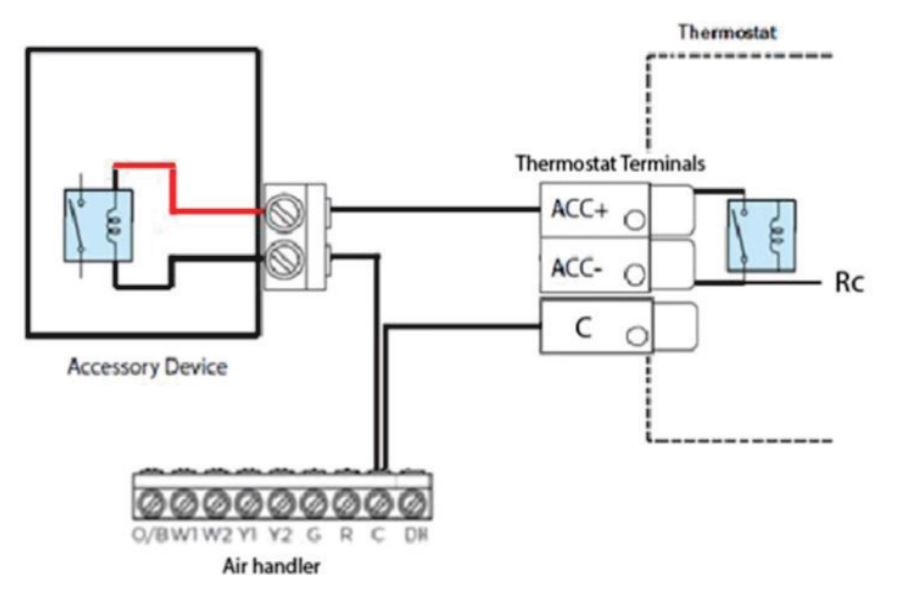

Humidifier (1-wire)

When the accessory is NOT internally powered, it needs power from the furnace or fan coil. Connect one wire to the ACC+ terminal on the thermostat and the other wire should be connected to Common. Because there is already a common wire from the start to the air handler, and since the humidifier is likely right next to the furnace, this is referred to as a 1-wire application because only one extra wire needs to run through the walls.

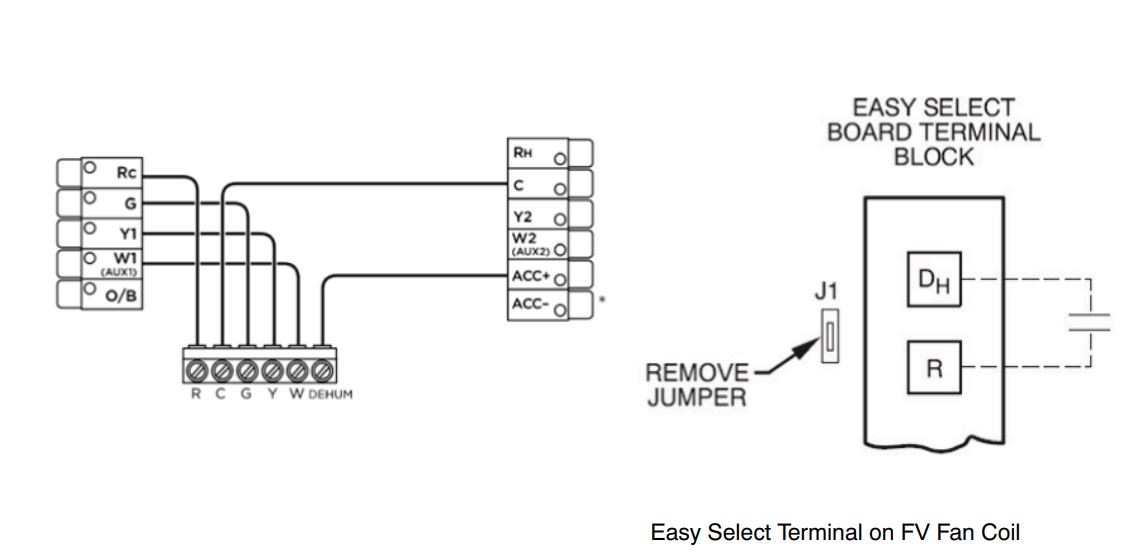

Dehumidification with DH or DEHUM Terminal (FV Fan Coil and Variable Speed Furnaces)

f the accessory terminals are not being used for a humidifier or whole house dehumidifier, then they may be used for the dehumidification feature integrated into Carrier FV fan coils and select variable speed furnaces. The ACC+ terminal will wire to the DH or DHUM terminal on the equipment in these applications. On the FV fan coils, remove jumper J1 from the Easy Select board to enable this feature.

Please also note that the equipment is expecting DH or DHUM to be energized during normal operation and DE-ENERGIZED on a dehumidification call from the thermostat. It is a reverse logic input, as compared to Y, G, W, etc.

Initial Start-Up

When the thermostat is first powered up, or after resetting the stat, a bee will be buzzing around the screen. This will be followed by the start of the initial configuration.

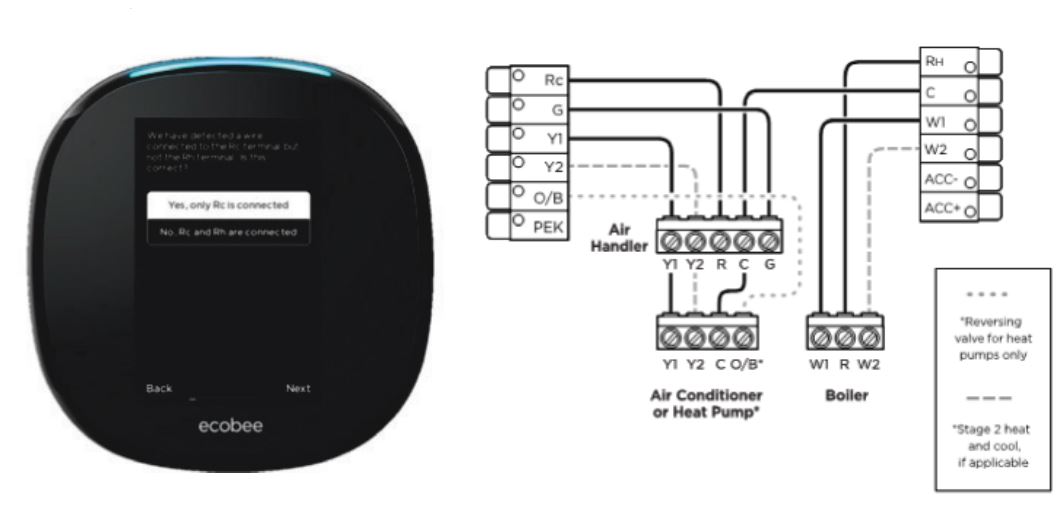

Initial Start-Up –> Power Source

A standard furnace with A/C or a fan coil with a heat pump will only have a single transformer and so only Rc is connected. It is important to note that in these applications, Rc must be used instead of Rh like some Carrier thermostats. If the heating and cooling equipment have separate transformers, such as a boiler with a fan coil and A/C, then both Rc and Rh are connected.

Start-Up –> Wiring -> Standard

In rare cases, the thermostat will not be able to detect certain wires. When this happens they can be added manually by selecting modify and then the connected wires on the thermostat display.

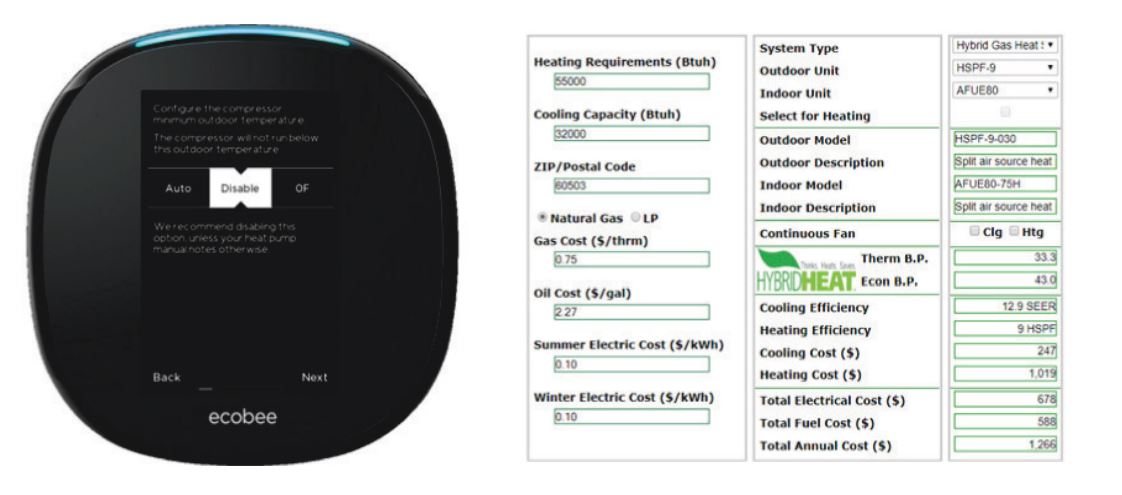

Select Enable If the auxiliary heat source is electric resistant and it is desired to have a heat pump and electric heat run at the same time. The system will provide heat pump heating at the lower stage and then turn on electric heat along with the heat pump at higher stages.

If it is a “dual fuel system,” meaning the auxiliary heat is a fossil fuel furnace, including natural gas, propane, or oil, then select Disable. Do not run the compressor and furnace at the same time to condition the home.

The minimum compressor outdoor temperature is based on the specific model of heat pump used in the system. Nearly all heat pumps can operate in the heating mode down to at least 17 degrees, as this temperature, along with 47 degrees, are the two AHRI standard testing points. The best temperature to disable the compressor depends on a lot of factors.

If the auxiliary heat is electric resistance, then shut off the compressor when either…Until that low temperature is reached, it is best to use the heat pump as the primary heat source and use the electric resistance as additional stages. Then below that temperature, shut off the compressor and use the electric heat only.

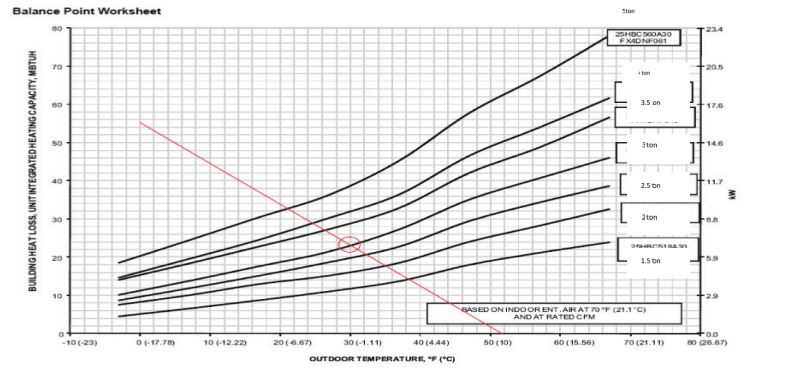

If the auxiliary heat is fossil fuel, then consider the cost of the fuel vs the cost of electricity, as well as the load of the house, the size of the equipment, and the models of the equipment. The online OpCost Calculator found on HVAC Partners can be used to determine the “thermal balance point” and the “economic balance point.”

This tool takes only a couple of minutes to use. The thermal balance point is the outdoor temperature at which the heat pump can no longer handle the load of the house on its own. The economic balance point is the outdoor temperature at which the furnace would be less expensive to run. Set the thermostat for the higher of these two numbers, so 43 degrees in the example above.

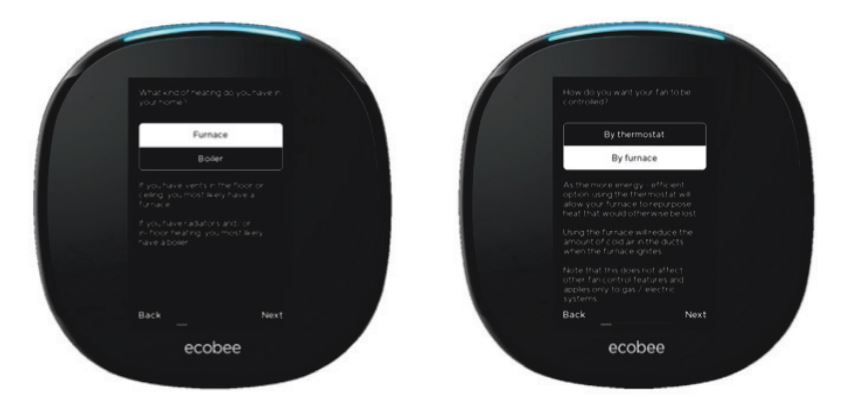

Initial Start-Up –> Furnace

The fan should be controlled by the furnace for all current CBP and ICP furnaces. This allows the furnace to delay the fan on a W1 allowing the heat exchanger to warm up before engaging airflow so the occupants do not get a blast of cold air. This setting only affects the gas heat startup sequence, it will not delay continuous fan or ventilation schedules, etc.

Initial Start-Up –> Humidifier

Typically, Steam should be selected as the humidifier choice even when an evaporative humidifier is installed. The ONLY difference between the two choices is that steam provides the option to humidify with a fan. There are no other differences.

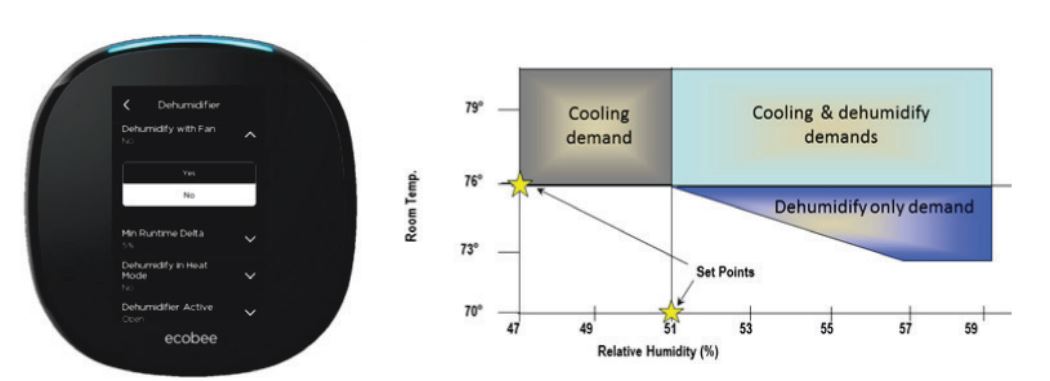

Installation Settings > Equipment > Humidifier > DeHum for Fan Coil or Furnace

When this feature is wired and set up along with AC Overcool Max, it allows multiple modes of cooling operation, including temperature-only demand, dehumidification demand, and both. When the DH or DHUM terminal on the equipment is energized, it will slow down the variable speed blower to increase the latent capacity of the evaporator coil, while reducing sensible capacity.

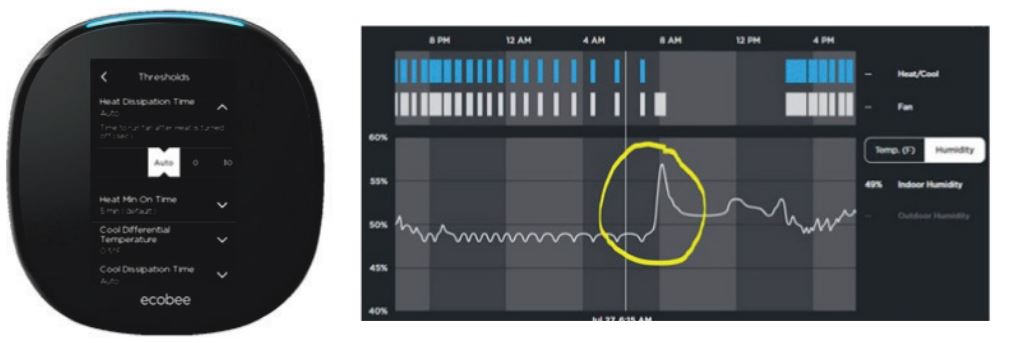

Installation Settings > Thresholds > Cool Dissipation

Cool Dissipation Time is the default, but the feature should only be used in very dry climates, such as Phoenix or Las Vegas. For the rest of the country, the fan should not tun at all after the cooling cycle is over.

Setting the Cool Dissipation Time from Auto to 0 will allow the moisture on the evaporator coil to run down into the drain pain and leave the system. If the fan were to continue running, much of that moisture would re-evaporate back into the home. The graph on the right illustrates humidity going back into the home after a cooling cycle as the fan blows air across a wet evaporator.

The Auxiliary Heat Maximum Outdoor Temperature specifies when the heat pump should be able to handle the heating load solo without the need for auxiliary electric heat to assist. Aux heat will be locked out above this temperature.

The OpCost Calculator mentioned on page 13 above can be used to determine the “Thermal Break Point” based on the house load and the heat pump model selected. The “Thermal Break Point” number often varies between 10 and 35 degrees. The default number is conservatively high at 35, and this should be lowered for most modern systems.

Alternatively, the house’s load profile can be manually plotted on the balance point worksheet in the product data book for each heat pump.

If Manual staging is selected instead of Automatic, then 5 additional staging options for the Auxiliary heat need to be configured. Unlike straight cooling projects where Manual Staging is recommended to be enabled so Reverse Staging could be utilized, the same recommendation is not made for heat pumps.

The Auxiliary Staging adds an extra layer of complexity into the mix, especially if there are 2 compression stages plus 2 auxiliary stages, so Automatic Staging should be selected on heat pump applications.

Installation Settings > Thresholds > Thermal Protect

The Thermal Protect range tells the thermostat the maximum difference allowed between the thermostat and the hottest or coldest rooms in the home. If a sensor measures a temperature that is significantly outside of this range, it probably means the reading is inaccurate. The thermostat will ignore this inaccurate reading to prevent the heating or cooling from running excessively. This setting is adjustable from 10 to 25 degrees.

Installation Settings > Thresholds > Installer Code

It is recommended that professionally installed thermostats be locked out by enabling the Installer Code. This prevents the homeowner from accidentally changing any of the settings in the Equipment, Thresholds, or Test Equipment settings.

This lockout feature is separate from the Access Control lockout and password that the homeowner can set for the homeowner settings. Write this code down as it is not well documented or easy to find online. The code cannot be changed, as is the same for all thermostats.

Training

My Learning Center is your central location for professional residential HVAC training resources that help strengthen careers and businesses. We believe in providing high-quality learning experiences both online and in the classroom. Access My Learning Center with your HVAC partner’s credentials at www.mlctraining.com.

FOR MORE MANUALS BY ECOBEE3, visit by MANUALSDOCK

FAQS About Carrier EB-STATE3LTCR-01 ecobee3 lite Pro Smart Thermostat

What is the Carrier EB-STATE3LTCR-01 ecobee3 lite Pro Smart Thermostat?

The Carrier EB-STATE3LTCR-01 ecobee3 lite Pro Smart Thermostat is a cutting-edge HVAC control device designed to optimize comfort and energy efficiency in homes and commercial spaces.

What are the key features of the ecobee3 lite Pro Smart Thermostat?

Key features include remote temperature sensing, energy usage tracking, smart scheduling, compatibility with voice assistants, and integration with smart home systems.

How does the ecobee3 lite Pro Smart Thermostat help save energy?

The thermostat uses advanced algorithms and occupancy sensors to adjust heating and cooling based on occupancy patterns, weather forecasts, and user preferences, resulting in significant energy savings.

Is installation difficult?

Installation is typically straightforward, especially for those familiar with basic HVAC wiring. However, it’s recommended to consult a professional installer for precise setup and compatibility verification.

Is the ecobee3 lite Pro compatible with my HVAC system?

It’s compatible with most heating, cooling, and heat pump systems, including multi-stage systems, but it’s essential to check compatibility with Carrier or consult a professional installer before purchasing.

Can I control the thermostat remotely?

Yes, the ecobee3 lite Pro can be controlled remotely using the ecobee app on your smartphone or tablet, allowing you to adjust temperature settings and monitor energy usage from anywhere.

Does it support voice commands?

Yes, the thermostat is compatible with voice assistants like Amazon Alexa, Google Assistant, and Apple HomeKit, enabling hands-free temperature control and other voice-activated features.

What is the warranty coverage for the ecobee3 lite Pro Smart Thermostat?

Carrier typically offers a limited warranty covering defects in materials and workmanship for a specified period from the date of purchase. Specific warranty details can be found in the product documentation.

Can I integrate it with other smart home devices?

Yes, the ecobee3 lite Pro supports integration with a wide range of smart home platforms and devices, allowing for seamless automation and control of your entire smart home ecosystem.

Where can I purchase the Carrier ecobee3 lite Pro Smart Thermostat?

You can purchase the thermostat through authorized Carrier dealers, HVAC contractors, or online retailers. Be sure to verify the authenticity of the product and warranty coverage before making a purchase.