Arlyn Scales 3200 Series

About Arlyn Scales

Arlyn Scales is a company that specializes in manufacturing and selling a wide range of industrial and laboratory scales and weighing equipment. The company is known for producing high-quality scales that are used in various industries, including manufacturing, healthcare, agriculture, and more. Here are some key points about Arlyn Scales:

- History: Arlyn Scales was founded in 1983 and is based in Long Island, New York. The company has decades of experience in designing and manufacturing scales.

- Product Range: Arlyn Scales offers a diverse range of scales, including bench scales, floor scales, platform scales, counting scales, crane scales, and more. They also provide specialized scales for specific industries and applications, such as hazardous area scales for use in potentially explosive environments.

- Technology and Innovation: Arlyn Scales is known for its commitment to innovation and technology. They have developed advanced weighing technologies, including ultrasonic distance sensors and digital signal processing, to enhance the accuracy and performance of their scales.

- Customization: The company offers customization options for their scales, allowing customers to tailor the equipment to their specific needs. This includes options for different sizes, capacities, and features.

- Software Integration: Arlyn Scales provides software solutions and integration capabilities to connect their scales to various data management systems, making it easier for businesses to track and manage their weighing data.

- Industries Served: Arlyn Scales serves a wide range of industries, including manufacturing, pharmaceuticals, logistics, agriculture, food processing, and more. Their scales are used for various applications, such as inventory management, quality control, and shipping and receiving.

- Customer Support: The company is known for its excellent customer support, assisting with scale selection, installation, calibration, and ongoing maintenance.

- Warranty: Arlyn Scales typically offers a warranty on their products, ensuring the quality and durability of their scales.

Features

- Easy to read, LCD Graphics display

- Automatic Calibration

- Multiple Tare Weights

- No Moving Parts

- Positive Overload Stops (most models)

- Large Memory Capacity

- Eight Unit Conversions Standard

- High Accuracy Parts Counting on Many Models

- Automatic or Numeric Entry Tare

- Sealed “Click-Type” Control Panel

- Abuse Resistant Stainless Steel Load Cell (most models)

- Computerized Self Testing

- Automatic Zero Tracking

- Full Text and Floating Point Entry

- On-Line Help

- Optional Time and Date

- Optional Battery Operation

- Optional Weight Average Function

- Optional Configurable RS-232 Port

- Optional Setpoints

- Optional Analog Output

- Optional Multiple Platforms

- Optional Windows Interface Software

Precautions

- Prevent inflammables and liquids from entering the scale head.

- Always use the included wall transformer when using an AC outlet. NEVER replace the wall transformer with a plug. This could cause electrical shock and severe damage to the scale.

- Allow clearance on all sides of the scale platform for accurate weighing.

- Do not drop large loads on a scale platform.

- NEVER EXCEED THE RATED CAPACITY OF THE SCALE.

- Do not pull on the connecting electrical cables.

- Make sure that the scale and ramps are properly secured to the floor (most models).

Initial Set-Up and Operation

- Carefully unpack the scale from the shipping carton. Save packing material for possible future use.

- If the level legs are included separately, then screw one into each corner underneath the scale.

- Place the scale on a level surface and adjust the level legs so that all four legs are touching the surface.

- If your scale comes equipped with ramps, fix them to the floor using the mounting holes provided. This way the ramp will not move during normal use. Be careful not to let the scale platform rub up against the ramp or any other surface, as this would cause non-repeatability of other inaccuracies.

- Plug into 117 VAC wall outlet.

- For non-battery pack-equipped scales, the scale will run a self-test procedure to check its load sensors and electronic

circuitry. Upon proper completion, the scale will display the prompt (“ready”). Press the ON/OFF key to activate the unit. Press and hold the ON/OFF key to return the scale to the ready state. For battery-pack-equipped scales, the screen will remain blank until you press the ON/OFF key. To shut the scale down, press and hold the ON/OFF key until the display blanks out. - Allow a five-minute warm-up time for stabilization and the most accurate results. Items to be weighed may be placed anywhere on the platform, but if heavy items are to be weighed, it is advisable to place them near the center. Many models are equipped with shock absorbers and positive overload stops for protection. Still, care should be taken to avoid putting excessive stress on the load cell system, as when heavy weights are dropped on the platform. It is normal for a small amount of drift to occur over periods. For the most accurate readings, the scale may re-acquire a true zero by using the ZERO button before weighing.

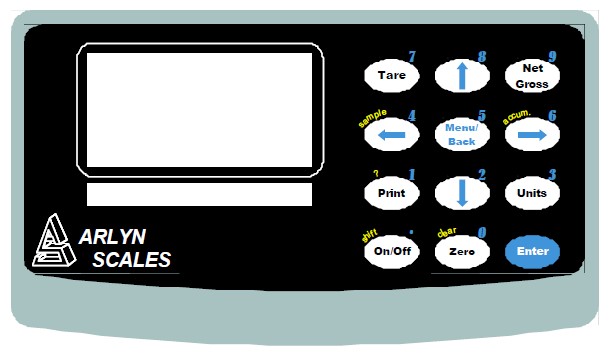

Front Panel / Keyboard

The front panel has a twelve-button, click-touch key panel that allows easy menu navigation as well as full text and floating point entry.

The main scale functions are shown in black, menu navigation and floating point numeric entry keys are blue, and the

secondary functions are yellow.

Main Function Keys

ON/OFF: Press once to place the scale in its normal operating mode. Pressing and holding the key will return the scale

to the “ready” mode. On battery pack equipped scales, press and hold this key to power it down.

TARE: Pressing this key will take any weight on the platform and switch the scale to the net mode. Holding this key

down will clear any active tare weight.

NET/GROSS: Will toggle the indicator between the net and gross mode. The net mode will show the weight on the platform minus any tared weight.

UNITS: Pressing this key allows you to step through the various conversions. By default, the conversions available are

pounds, kilograms, grams, and ounces. There are four other conversions available that can be activated in the setup menu. This will add troy ounces, pennyweights, grains, and a user-defined conversion to the list.

ZERO: Will zero the indicator.

Menu Navigation Keys

MENU/BACK: Using this key from the weight display will access the setup menu. In all other areas, it is used to back out from menus or to complete an operation.

ENTER: This key is used to select items and to complete operations in the various menus.

ARROWS: These are used to navigate and select menu items.

Secondary Function Keys

SAMPLE: In counting, scales are used to acquire a quick parts counting sample from the platform. Pressing and holding

this key down will clear the active sample.

ACCUM: In counting, scales are used to add the piece count to the accumulated register allowing the totaling of parts. Pressing and holding this key will clear the accumulated register.

? KEY: This can be used in various areas to call up help screens. In some areas, this key needs to be pressed and held.

SHIFT: Used by the text-editing screen to toggle caps on/off.

CLEAR: Used in some editing screens to clear input lines and numbers. In some areas, this key needs to be pressed

and held.

NUMBER KEYS: These are used in various places to input floating point numbers.

System Operation

Basic Menu Operation

The scale operating system uses a menu-driven interface that is both intuitive and easy to use. To access the setup menu press the MENU/BACK key.

There are two basic menu types. The first is a simple list of items. To select an item in the list, use the UP and DOWN

ARROW keys to line up on the desired item and then press ENTER.

The second type of menu is a horizontal list displayed at the bottom of the screen. These menu items indicate operations to be performed. To select one, use the RIGHT and LEFT ARROW keys to select the desired item and then press ENTER.

Horizontal menus may show a single or double-headed arrow on the right side to indicate that there are more selections to the left and/or right that are not displayed.

Horizontal menus and lists are often used together to operate on a specific item. For example, to delete a tare entry, use the UP and DOWN ARROWS to select the desired tare from the list, then use the LEFT and RIGHT ARROWS to select the menu item “DEL” in the horizontal menu. Pressing ENTER will operate.

Selecting menu items will often lead to other menus, sometimes drilling down several levels deep. Use the MENU/BACK key to back your way out. Continuing back will eventually bring you back to the top, which is the main weight display screen. Consult the menu tree in the back of the manual for help in navigating menus.

Parts Counting Functions (Series 8200)

Parts counting mode enables you to count parts automatically on the platform. To be accurate, the parts you are counting must be of a consistent weight from piece to piece and be heavy enough to be detectable by the scale. Scales that have low maximum capacities can count very light parts while scales of heavier capacities can only count heavier parts. Attempting to count parts that are too light will cause the indicator to drift and become non-repeatable.

Parts counting is a two-step process, first, the scale needs to know how much each part weighs. This is called

sample acquisition. Second, the counting mode must be activated with the desired sample.

There are two ways to acquire a sample. One way is to take a quick sample on the platform from the front panel. The other way is to use the setup menu where samples can be taken, named, stored, and activated similarly to tares. Multiple platform scales have the distinct advantage of allowing you to take your sample on a low-capacity platform (to get a very accurate sample) and do the actual counting on a large-capacity platform.

Sample Acquisition

There are two methods for acquiring samples. The first is the “Quick Sample” method and the second is to define a sample in the scale’s memory for permanent storage. In general, the more parts that you use during your sample acquisition the more accurate your parts counting will be. Using a quick sample restricts you to sample sizes of 10, 25, 50, or 100 pieces. This is acceptable in many circumstances, especially when the parts are fairly heavy. Saving a sample in memory allows you to choose any size sample, and is far more accurate.

Quick Sample

The quick sample is limited to sample sizes of 10, 25 50, and 100 pieces, which is all that is required for many operations. To take a quick sample, press the SAMPLE key. The number 10 will be displayed. Press the LEFT ARROW until the desired sample size is displayed, and then press ENTER. For best general accuracy use the largest convenient sample size. Remove all weight, place an empty container on the platform, and press ENTER.

Place the correct amount of parts on the platform and then press ENTER. The scale will now automatically switch to a

counting screen. Quick samples can not be stored for future use and will remain active only until the power is removed, a new sample is taken or the sample is cleared through the keyboard. Proceed to the section “Counting Parts”.

Accumulate Function

Your scale has an accumulate function that will allow you to keep a running total of parts counted. To activate, place your parts on the platform and then press the ACCUM key. “Acc” will be shown on the display and the number of parts that were on the platform will be added to the accumulated register. While in the accumulate mode, the display will show what is in the accumulate register PLUS the number of parts on the platform. To clear the accumulated register, press and hold the ACCUM key until it clears.

The System Menu

The system menu contains many useful features for checking and configuring your scale. To access, select menu SETUP

MENU/SYSTEM. Each feature is outlined below.

- Scale Description / Scale ID Number

Each scale can be assigned a unique description and ID number. This is useful for printing labels and other processes. - Udef Conversion Multiplier

Allows you to enter the multiplier (from pounds) for the user-defined conversion. - Auto Increment Weight Number

This number will increment each time the PRINT button is pressed. It can be useful in label printing and statistical operations. Its starting value can be set here. - Display Contrast

Allows you to adjust the contrast of the display for optimum viewing. - Memory Status

Will give a detailed breakdown of memory slot usage and free memory available. The number indicated is the number of slots, not the number of definitions. Each definition uses memory differently. See the section above entitled “System Memory Allocation and Usage”. - Display Update Speed

The display update speed can be adjusted from .1 to six seconds. - Startup Parameters

The following startup parameters can be set here;

a) The startup screen and conversion units can be set here.

b) The “ready” prompt and the splash screen can be enabled/disabled.

c) Zero lock can be enabled/disabled. Zero lock disables the front panel ZERO key. When this function is enabled the user must press the ZERO and the PRINT key simultaneously to zero the scale. - Erase User Memory

The entire user memory can be erased at one time, if necessary, using this option. It will erase all user-defined tares, counting samples, text definitions, print frames, and setpoints but will leave platforms and other system memory intact. - Revision Number

Reads out the current operating system revision number. - Auto Shut-Off

Auto Shut-Off allows you to set your scale to automatically shut off when a preset time limit has been reached and there has been no activity on the scale. This feature is mainly used on battery pack-equipped scales to prevent the battery from inadvertently being deep discharged. Auto Shut-Off can also work on non-battery equipped scales but its operation is slightly different. In a battery-equipped scale, the unit will completely shut down and the display will blank. The scale can later be turned on again using the normal means. On non-battery equipped scales, the display will blank but the scale will remain in the same condition as when it shut down. Zero, active tare, and active parts counting samples as well as the current screen will all be retained. Pressing any key will return the scale to its normal operating mode.

An inactive scale can be defined as no keys being pressed, and there has been no activity on the platform. It should be noted that anything that causes a small increase or decrease in the platform reading will be considered an active platform. Avoid vibrating surfaces, digital filtering constants of non-factory default values, or anything else that causes the platform reading to drift if this feature is used. To configure Auto Shut-Off, go to the menu SETUP MENU/SYSTEM/AUTO SHUT-OFF. There are two settable options available.

ACT: Activates/deactivates the auto shutoff feature.

TIME: This is the time, in minutes, that the unit will shut off due to inactivity. Any time from 1 to 25 minutes can be used.

Calibration and Troubleshooting

Your scale has been precisely calibrated at the factory before shipping. It can adjust its calibration to a certain degree to compensate for aging electronics and temperature changes. This being the case, you may never have to calibrate the scale. Doing so may leave you with a worse calibration than you started with. Does your scale need to be calibrated? If so what steps are needed? Follow the steps outlined below to help make this determination.

The scale reads zero and will not move.

- Make sure that any shipping screws are removed from the platform.

- On platform scales, check that all four level legs are contacting solidly against the floor.

- If level legs are screwed in all the way then the stud from the level leg may be contacting the underside of the platform

not allowing the load sensor to flex.

Scale reading fluctuates wildly.

- The scale must be on a non-vibrating surface. Breezes may affect scales of lighter capacities.

- The scale must be installed on a clean power line. Electric motors, computers, or any other devices can cause power line interference.

- RF interference can cause scale readings to fluctuate. Are there any transmitters nearby like cell phones or walkie-talkies?

- If the scale is a remote platform type, check to see if the cable from the platform to the indicator in plugged in properly. If so then remove the plug temporarily to check for bent or missing pins.

- Check for nicks or cuts on the platform cable.

Scale reading is different in different areas on the platform.

- On platform scales, check that all four level legs are solid against the floor. If a level leg is screwed in all the way then the stud from the level leg may be contacting the underside of the platform not allowing the load sensor to flex.

- Check for any mechanical interference. Is there anything rubbing against the platform? Scale corners properly but do not indicate the correct weight.

- On platform scales check that all four level legs are solid against the floor.

- Check for any mechanical interference. Is there anything rubbing against the platform?

- Perform span calibration.

Limited Warranty

Arlyn Scales warrants that your Arlyn Scales equipment and systems, when properly installed will operate per written

specifications. All systems and components are warranted against defects in materials and workmanship for one year.

Arlyn Scales warrants that the equipment sold hereunder will conform to the written specifications authorized by Arlyn

Scales. Arlyn Scales warrants the equipment against faulty workmanship and defective materials. If any equipment fails to conform to these warranties, Arlyn Scales will, at their option, repair or replace such goods returned within the warranty period subject to the following conditions:

- Upon discovery by Buyer of such nonconformity, Arlyn Scales will be given prompt written notice with a detailed

explanation of the alleged deficiencies. - Individual electronic components returned to Arlyn Scales for warranty purposes must be packaged to prevent electrostatic discharge (ESD) damage in shipment.

- Examination of such equipment by Arlyn Scales confirms that the nonconformity exists, and was not caused by accident, misuse, neglect, alteration, improper installation, improper repair, or improper testing; Arlyn Scales will be the sole judge of all alleged non-conformities.

- Such equipment has not been modified, altered, or changed by any person other than Arlyn Scales.

- Arlyn Scales will have reasonable time to repair or replace the defective equipment. The buyer is responsible for shipping both ways.

- In no event will Arlyn Scales be responsible for travel time, or on-location repairs, including assembly or disassembly of equipment, nor will Arlyn Scales be liable for the cost of any repairs made by others.

For more manuals by Arlyn Scales, Visit Manualsdock

[embeddoc url=”https://manualsdock.com/wp-content/uploads/2023/10/Arlyn-Scales-3200-Series-Instruction-Manual.pdf” download=”all”]