Whirlpool Super Capacity 465 Freestanding Gas & Electric Ranges

About Whirlpool

“Whirlpool” is a brand of home appliances that include refrigerators, freezers, washing machines, dryers, dishwashers, ovens, and ranges. The brand is known for its innovative features, including the AccuBake temperature management system for ovens, the 6th Sense technology for washing machines and dryers, and the TotalCoverage spray arm for dishwashers. The Whirlpool brand is owned by the Whirlpool Corporation, which is an American multinational manufacturer and marketer of home appliances. The company has a presence in over 170 countries and is one of the world’s largest manufacturers of home appliances.

FORWARD

This Job Aid will introduce the technician to the Whirlpool Ranges. This Job Aid is a reference guide for experienced technician. It is not designed as a replacement to basic training. This Job Aid does not replace the Service Manual or the Use and Care Guide. It is designed to be used in conjunction with these manuals.

OBJECTIVE

The objective of this Job Aid is to have the experienced appliance technician become familiar with the operation and service of the Whirlpool Ranges. It is designed as reference material and is not a replacement for basic training.

FIVE KEY BENEFITS & FEATURES

- The Largest Oven Capacity In The Industry

- The Super Capacity 465™ Range offers more oven space than any other range in the industry—4.65 cubic feet.

- Large meals are never a problem with the spacious capacity.

- Save time by cooking multiple meals and freezing them for the busy days ahead.

- Consistent Cooking Results

- AccuSimmer™ burners on gas ranges provide precise low-heating for delicate sauces and chocolates (Models SF385 & SF395).

- Food cooks evenly throughout the oven cavity.

- Electronic controls maintain oven temperature swings within ±20˚F.

- AccuBake™ Triple Cycling Elements on electric models with EZ-Touch 200 & EZ-Touch 300 oven controls.

- Custom Broil allows the selection of temperature from 300˚F to 525˚F (300˚F to 500˚F on electric ranges) so that everything from fish to steaks broil perfectly (on all Touch Control models).

- Easy-To-Use Controls

- Whirlpool EZ-Touch™ Electronic Controls offer the following innovative features:

- One-Touch operation sets Bake at 350˚F, and Self-Clean for 3.5 hours.

- Exclusive Preheat Countdown visually indicates the time required for oven preheating. The oven control beeps when the preset temperature is reached.

- Child Lockout disables the control panel to prevent children from accidentally turning the oven on.

- Easy to understand left-to-right programming logic.

- Color-Keyed touch pads.

- Whirlpool EZ-Touch™ Electronic Controls offer the following innovative features:

- Easy To Clean

- Spillguard™ Cooktop has raised edges to help contain spills. Porcelain surfaces wipe clean with a damp sponge.

- CleanTop™ Ranges offer radiant elements under a one-piece, smooth ceramic glass surface for easy clean up.

- Seamless cooktop on coil ranges lifts easily for cleaning the burner box.

- Automatic door lock for self-clean ovens requires no external latch to lock the oven door for the Self-Clean cycle.

- Modern Design

- Stylish cabinet depth design offers a built-in look.

- A modern curved console and a one-piece solid handle are designed with no exposed screws or unsightly trim.

- A hidden vent.

- 200-degree rotation infinite flame setting valves on gas ranges (SF385 & SF395) offer optional ergonomic, one-turn operation, while allowing precise burner management.

- Whirlpool “Family Look” styling compliments an entire kitchen of Whirlpool appliances.

WARNING LABELS

This manual is intended for factory-service technicians only. We recommend that customers DO NOT service their own units, because of the complexity and risk of high-voltage electrical shock.

The following information is used throughout this manual, and should be read carefully.

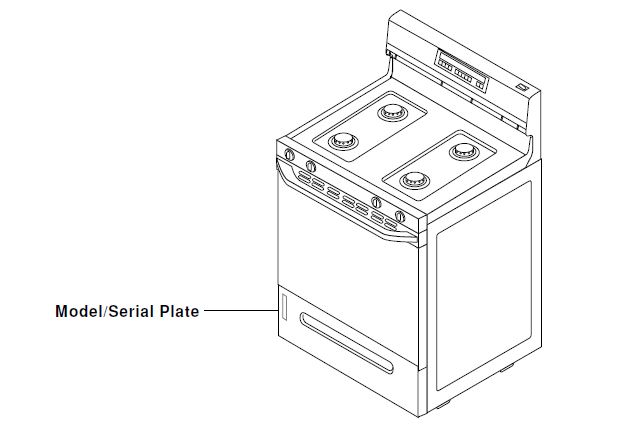

MODEL & SERIAL NUMBER LOCATION

The Model/Serial Number Plate is located behind the broiler/storage drawer.

SERIAL NUMBER DESCRIPTION

The serial number can be decoded by using the following example:

SERIAL NUMBER: RF 36 50001

- R = Manufacturing Location (Tulsa, OK)

- F = Year of Manufacture (1996)

- 36 = Week of Production (36th week)

- 50001 = Sequence of Range

GAS RANGE MODEL NUMBER

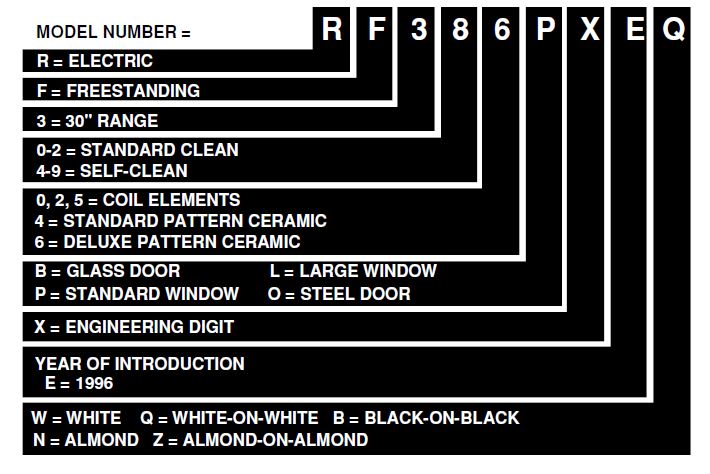

ELECTRIC RANGE MODEL NUMBER

MODELS WITH ELECTRONIC CONTROLS Gas Ranges

The following chart shows the gas range models with electronic controls:

| OVEN CONTROL | WHIRLPOOL | ROPER | ESTATE |

| K.E.T. | SF350BEE** | FGS335E** | |

| EZ-100 | SF360BEE** | ||

|

EZ-150 |

SF315PEE |

TGS325E** |

|

| SF372BEE** | |||

| SF375BEE** | |||

|

EZ-200 |

SF325PEE | ||

| SF385PEE** | |||

| EZ-300 | SF395LEE** |

Self-Clean Model

Electric Ranges

The following chart shows the gas range models with electronic controls:

| OVEN CONTROL | WHIRLPOOL | ROPER | ESTATE |

|

K.E.T. |

RF350PXE** | FES330E** | |

| RF354BXE** | FES364E | ||

|

EZ-100 |

RF360BXE** |

TES325E** |

|

| RF364BXE** | |||

| RF375BXE** | |||

|

EZ-150 |

RF315PXE** | ||

| RF372BXE** | |||

| RF375PXE** | |||

| RF376PXE** | |||

|

EZ-200 |

RF324PXE | ||

| RF325PXE | |||

| RF385PXE** | |||

| RF386PXE** | |||

|

EZ-300 |

RF395LXE** | ||

| RF396LXE** |

Self-Clean Model

Electric Ranges

The following chart shows the electric range models with electronic controls:

Self-Clean Model

OVEN CONTROLS

The Super Capacity 465 ranges use one of the following five electronic controls:

K.E.T. Single-Knob Control

(Knob With Electronic Thermostat)

This oven control includes: Bake Temperature settings with Broil and Clean, Oven On, Oven Heating, & Door Locked/Cleaning indicators

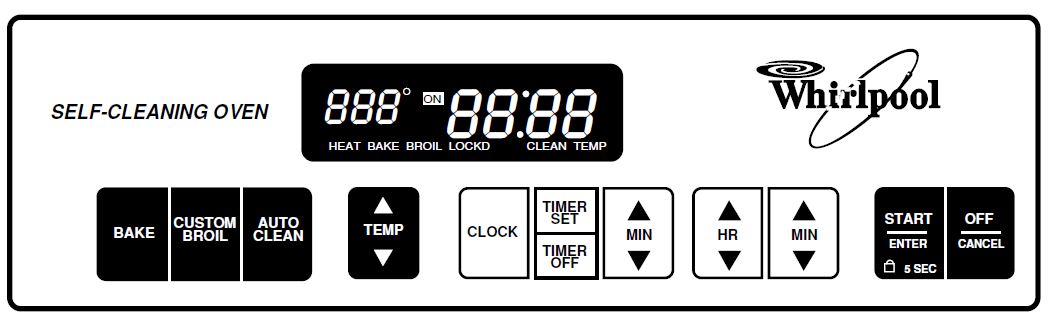

EZ-Touch™ 100

This oven control offers an electronic LED Display, Indicator Lights, Custom Broil, Auto Clean, Child Lockout, and Start Prompt (no Time-Of-Day function).

EZ-Touch™ 150

Adds a Time-Of-Day Clock, Color-Keyed Temperature and Clock/Timer Pads, Electronic Minute Timer and Signal.

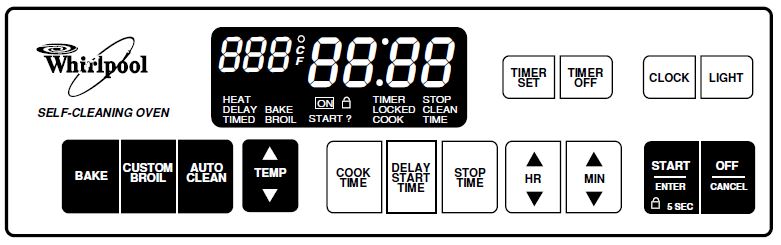

EZ-Touch™ 200

Adds an Illuminated Vacuum Fluorescent Display, AccuBake Tempera-ture Management System, Separate Time/Temp Displays, and Inte-grated Light Touch Pad.

EZ-Touch™ 300

Adds Delay Cook and Off functions.

USING THE OVEN CONTROLS

To set the various oven control functions, use the following procedures:

- CHILD LOCKOUT

- Press and hold START for 5 seconds.

- TEMPERATURE ADJUSTMENT

- Press and hold BAKE for 4 seconds.

- Press TEMP UP or DOWN arrow.

- Press START.

- FAHRENHEIT/CELSIUS CONVERSION

- Press and hold the CUSTOM BROIL for 5seconds.

- ADJUSTABLE AUDIBLE SIGNAL

- Press and hold STOP TIME for 5 seconds.

- CLOCK DISABLE

- Press and hold CLOCK for 5 seconds.

- DEMO FEATURE

- Press and hold TIMER SET for 5 seconds.

- PREHEAT COUNTDOWN TIMER AND SIGNAL

- Press BAKE.

- Press START.

- CUSTOM BROIL

- Press CUSTOM BROIL

- Press TEMP.

- Press START.

- SELF-CLEAN COUNTDOWN TIMER

- Press AUTO CLEAN.

- Press START.

- CANCEL OR STOP

- Press CANCEL.

- ELECTRONIC TIME-OF-DAY CLOCK

- Press CLOCK.

- Press TEMP.

- Press START.

- ELECTRONIC MINUTE TIMER AND SIGNAL

- Press TIMER.

- Press TEMP.

- Press START.

- To cancel or turn off the Timer, press TIMER twice.

- TO USE COOK TIME

- Press COOK TIME.

- Press HR & MIN.

- Press START.

- TO USE STOP TIME

- Press STOP TIME.

- Press HR & MIN.

- Press START.

- TO USE COOK TIME AND DELAY START TIME

- Press COOK TIME.

- Press HR & MIN.

- Press START.

- Press STOP TIME.

- Press HR & MIN.

- Press START.

- START PROMPT

- Press START to begin the selected function.

ACCUSIMMER™ BURNER

The AccuSimmer™ (right rear) burner is designed to provide 550 B.T.U.s for precise, low-heat cooking.

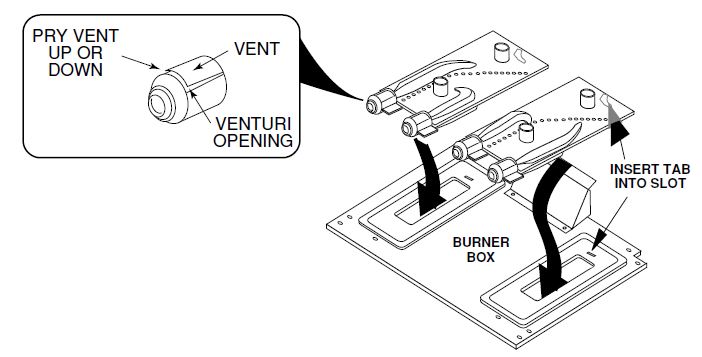

THE VENTURI SYSTEM

The exclusive sealed gas venturi burners provide precise, even flame control so that each burner stays lit, even under sudden draft conditions. Airflow to the front and rear burners is adjusted at the front of the venturi by prying the slots open or closed, or by rotating the air shutters.

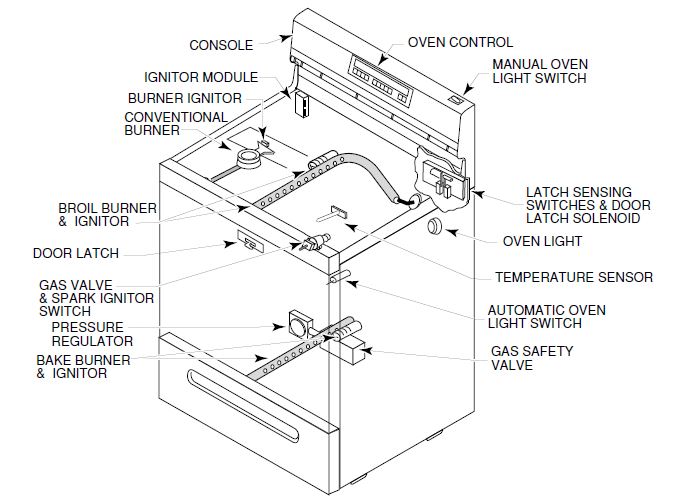

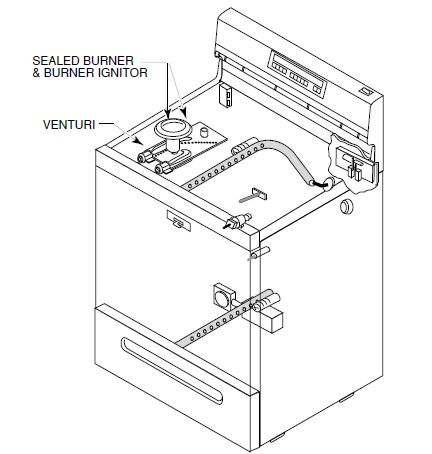

GAS RANGE COMPONENT LOCATIONS Conventional Burners

Sealed Burners

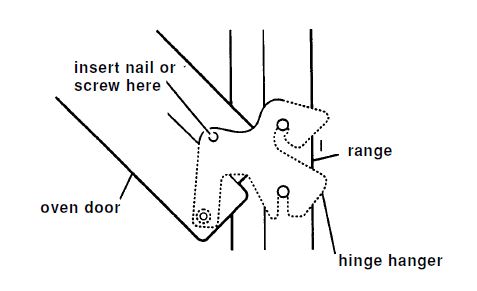

OVEN DOOR REMOVAL

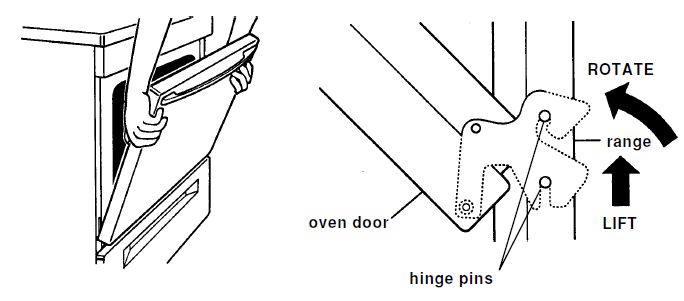

The procedure for removing the oven door is the same for both gas and electric ranges. The door removal is different from previous ranges. To remove the door:

- Open the door half way and install a nail or a screw into the hinge hanger holes on both sides of the door.

- Close the oven door as far as the nails or screws will allow, lift the door off the two hinge pins, pull the door towards you so that the hinges are free of the slots, and remove it.

REMOVING A MAINTOP

- Push the front of the maintop to the left and lift the left corner, then unclip and lift the other corner, and raise the front of the maintop

- Slide the maintop to the right and remove the left hinge pin from the hinge bracket,then free the right hinge pin from its bracket, and remove the maintop

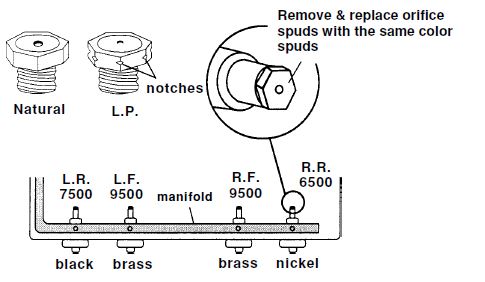

L.P. CONVERSION

L.P. Conversion Kits will be shipped with the product. Kits include four top burner orifice spuds. The kit numbers are as follows:

Kit #3196473—Sealed Burner Models

- (2) #65 spuds–8500 B.T.U. (brass)

- (1) #68 spud–6500 B.T.U. (black)

- (1) .7 mm spud–5500 B.T.U. (nickel)

Kit #3196471—Open Burner Models

- (4) #66 spuds (8000 B.T.U. each)

ORIFICE SPECIFICATIONS

| SUGGESTED DRILL SIZE |

COLOR |

STAMPING |

BTU RATING |

| 1.45 MM | BRASS | NAT | 9,500 |

| NO. 65 | BRASS | L.P. | 8,500 |

| NO. 55 | BLACK | NAT | 7,500 |

| NO. 68 | BLACK | L.P. | 6,500 |

| 1.2 MM | NICKEL | NAT | 6,500 |

| .7 MM | NICKEL | L.P. | 5,500 |

| NO. 54 | BRASS | NAT | 9,000 |

| NO. 66 | BRASS | L.P. | 8,000 |

| SPUD KIT NUMBER | SPUD # & QTY. | DESCRIPTION |

| 3196471 | 3196211 (4) | L.P. Conversion (Open Burner) |

| 3196450 (2) | L.P. Conversion (Sealed Burner) | |

| 3196473 | 3196335 (1) | |

| 3196336 (1) | ||

| 3196474 | 3196643 (4) | Nat. Gas Spud Kit (Open Burner) |

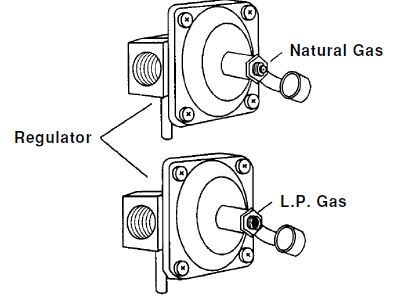

L.P. CONVERSION

Turn the orifice hoods on the oven burner(s) down 2-1/2 – turns.

Reverse the regulator cap so that LP faces up.

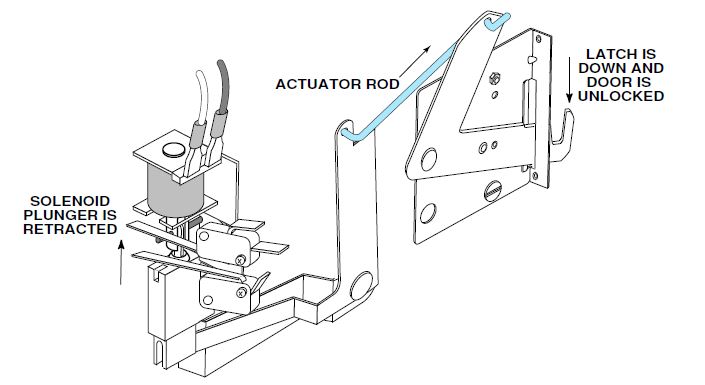

OVEN DOOR LOCK SYSTEM

The oven door lock system uses a solenoid-activated, push-push mechanism. The oven door will lock as soon as it is closed and the CLEAN function is programmed into the Electronic Oven Control (EOC). When the solenoid is activated, the plunger extends, and the actuator rod moves the latch to lock the door.

After the CLEAN cycle is completed and the temperature inside the oven cavity falls below 500˚F, the latch solenoid relay closes and activates the door lock solenoid. The solenoid plunger retracts, and actuator rod pulls the latch and unlocks the oven door.

IGNITION SYSTEM OPERATION

OHMS LAW:

I = E/R

AMPS = VOLTAGE DIVIDED BY RESISTANCE

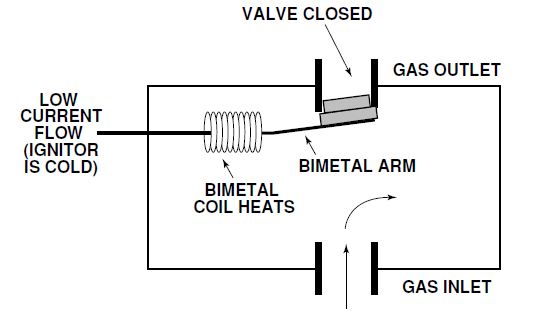

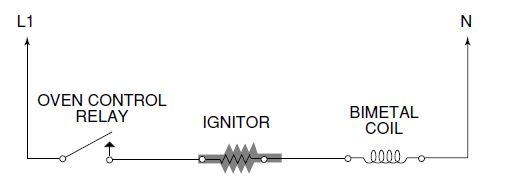

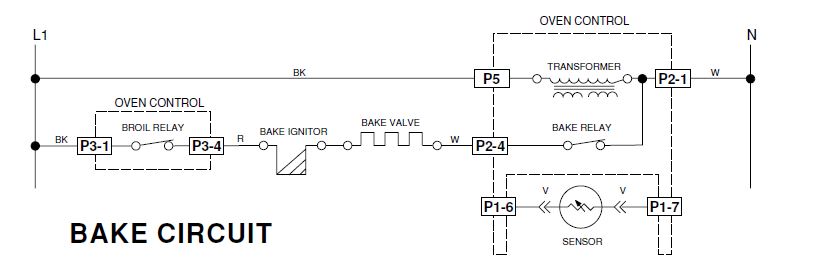

A cold ignitor has a high resistance. When the oven control relay closes

Current flows through the ignitor and the bimetal coil.

High ignitor resistance causes low current flow through the bimetal coil. As the ignitor heats up, its resistance decreases.

Lower ignitor resistance increases the current flow through the bimetal coil. When the ignitor is fully heated, its resistance is low. Low resistance causes maximum current to flow through the bimetal coil (2.5 to 3.6 amps).

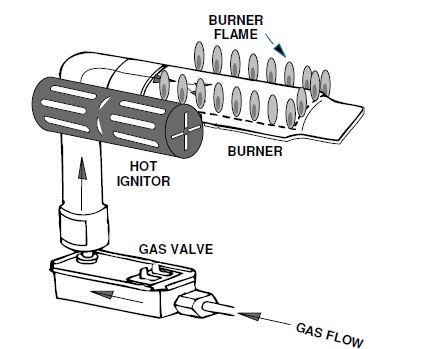

As the bimetal coil heats, it heats the bimetal arm inside the gas safety valve.

As the bimetal arm heats, it bends and opens the gas safety valve outlet to the burner.

The gas at the burner is lit by the hot ignitor and a flame is produced.

When the oven reaches its selected temperature, the oven control relay opens, and power is removed from the circuit. With no voltage applied, the ignitor and bimetal coil start to cool.

The bimetal arm cools, bends to its original position, and closes the gas safety valve.

The burner flame is extinguished.

TYPICAL GAS RANGE WIRING DIAGRAM

K.E.T., EZ-100 & EZ-150 Controls

GAS RANGE STRIP CIRCUITS

K.E.T., EZ-100 & EZ-150 Controls

OVEN DOOR LOCK SYSTEM CURRENT FLOW

Voltage is supplied to the control transformer whenever the range is plugged in. Current flows from L1, through the transformer, to the neutral side of the line. When voltage is supplied to the EOCs Latch Solenoid Relay, current flows through the Latch Solenoid, to the neutral side of the line.

THE OVEN TEMPERATURE SENSOR

The oven temperature sensor is a “Resistance Temperature Detector” (RTD), and is composed of a stainless steel tube with a thin film of platinum at the end. It is located at the upper left rear corner of the oven cavity. The RTD is a nonadjustable assembly, but may be checked at room temperature, or at 350˚F. A sensor resistance of less than 550 ohms is regarded as a shorted sensor, and a resistance greater than 3000 ohms is regarded as an open sensor. When the oven control senses a resistance of less than 550 ohms, and greater than 3000 ohms, the bake and broil functions will be turned off.

To test the oven temperature sensor, perform the following steps:

| Temperature (˚F) | Resistance (W) |

| 32 ± 1.9 | 1000 ± 4.0 |

| 75 ± 2.5 | 1091 ± 5.3 |

| 250 ± 4.4 | 1453 ± 8.9 |

| 350 ± 5.4 | 1654 ± 10.8 |

| 450 ± 6.9 | 1853 ± 13.5 |

| 550 ± 8.2 | 2047 ± 15.8 |

| 650 ± 8.6 | 2237 ± 18.5 |

| 900 ± 13.6 | 2697 ± 24.4 |

- Use an ohmmeter and set the range switch to R x 10.

- With no power applied, touch the leads of the ohmmeter to the connector pins of the sensor (you do not have to separate the connectors). Depending upon the oven temperature, you should obtain the corresponding reading shown in the chart:

ELECTRIC RANGE COMPONENT LOCATIONS

For a description and test procedure for the Oven Temperature Sensor, refer to the previous page.

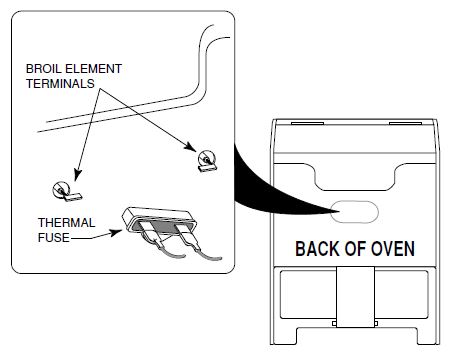

OVEN THERMAL FUSE

The oven thermal fuse is located on the back of the range. A thermal fuse is used on electric models with EZ-200 and EZ-300 oven controls.

ACCUBAKE™ TEMPERATURE MANAGEMENT SYSTEM

The AccuBake™ Temperature Management System provides better baking results. Both the Bake and Broil elements can cycle independently or together to maintain more even temperatures.

The following “Relay Cycling Chart” shows how the relays operate the two elements to obtain various bake and broil temperatures.

Relay Cycling Chart

| Electric (Pyro) | Gas (Pyro) | Electric (Non-Pyro) | Gas (Non-Pyro) | |

|

Bake Preheat Time & Temperature Ranges |

170˚ – 245˚

2 min. 30 sec. 250˚ – 445˚ 4 min. 15 sec. 450˚ – 500˚ 6 min. 30 sec. |

170˚ – 245˚

4 min. 250˚ – 445˚ 10 min. 450˚ – 500˚ 15 min. |

170˚ – 245˚

2 min. 30 sec. 250˚ – 445˚ 4 min. 15 sec. 450˚ – 500˚ 6 min. 30 sec. |

170˚ – 245˚

4 min. 250˚ – 445˚ 10 min. 450˚ – 500˚ 15 min. |

| Bake Preheat Relay “ON” Time | Bake % = 100 Broil % = 40 | Bake % = 100 | Bake % = 100 Broil % = 40 | Bake % = 100 |

| Bake Relay “ON” Time | Bake % = 60 Broil % = 20 | Bake % = 100 | Bake % = 60 Broil % = 20 | Bake % = 100 |

| Broil Relay “ON” Time | Broil % = 100 | Broil % = 100 | Broil % = 100 | Broil % = 100 |

| Clean Preheat Relay “ON” Time | Bake % = 60 Broil % = 40 | N.A. | N.A. | N.A. |

| Clean Relay “ON” Time | Bake % = 80 Broil % = 70 | Bake % = 100 | N.A. | N.A. |

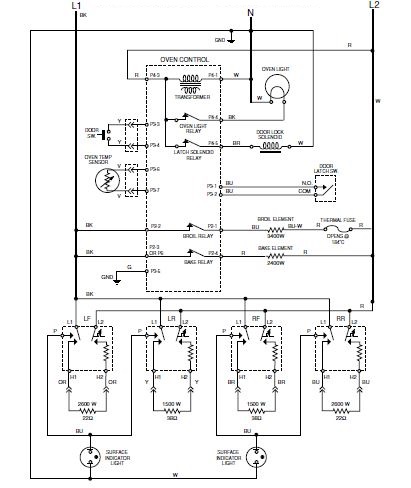

ELECTRIC RANGE WIRING DIAGRAM

EZ-200 & EZ-300 Oven Controls

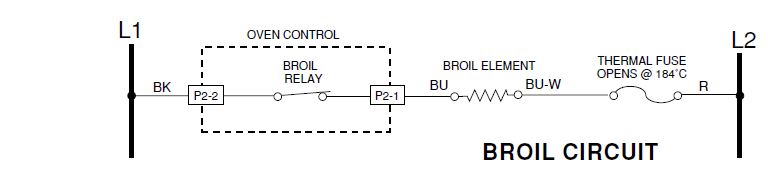

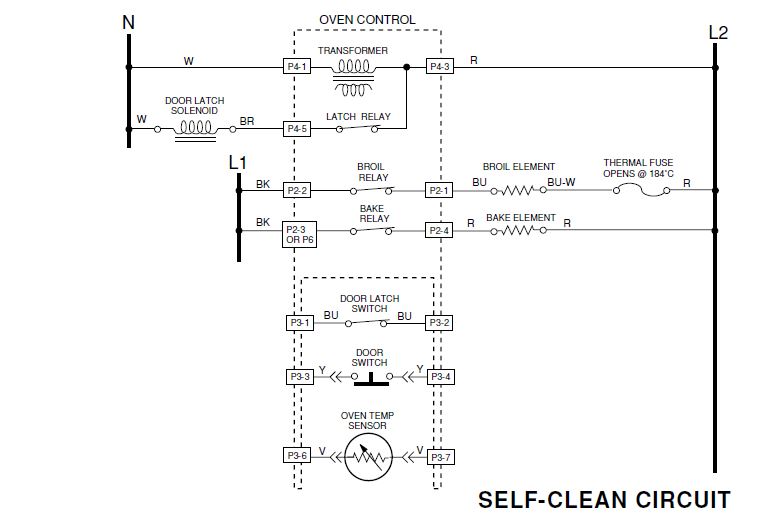

ELECTRIC RANGE STRIP CIRCUITS

EZ-200 & EZ-300 Oven Controls

CONFIRMATION OF UNDERSTANDING

- The oven door lock mechanism is a

- push-push design.

- push-pull design.

- dual-solenoid design.

- manually operated design.

- The oven door is removed by

- `loosening the two screws at the inner door panel and lifting up.

- removing the oven side panel and loosening the retaining brackets.

- opening the door to the broil stop position, inserting screws or nails in the hinge holes and lifting the door, then rotating it forward.

- sliding the lower part of the door forward to release the hinges.

- The surface burners are converted to L.P. by

- adjusting the universal type hoods at the burner valves.

- replacing the spuds in the burner valves with L.P. spuds.

- adjusting the venturi at the burner valve.

- These burners cannot be converted to L.P.

- The oven cavity in the SC465 range line is

- the largest in the industry.

- the smallest in the industry.

- average size within the industry.

- within 5% of being the largest in the industry.

- AccuBake in the electric range line indicates

- the bake and broil elements are controlled by sensitive percentage switches.

- the oven temperature is held to within 5 degrees of the set temperature.

- the oven rack position is no longer important.

- the bake and broil elements will cycle independently.

- EZ-Touch indicates the

- feel of the oven door handle.

- operation of the surface burner knobs.

- programming of the electronic oven control.

- None of the above.

- The sealed gas burner venturi can be adjusted by

- loosening the screw at the slide cover and turning the cover to the desired setting.

- prying the venturi slot open with a flat-bladed screwdriver.

- replacing the venturi assembly with an L.P. venturi assembly.

- Sealed gas burners do not have venturi adjustments.

- All SC465 ranges utilize an oven thermal fuse.

- True

- False

- On ranges using the K.E.T., EZ-Touch 100, and EZ-Touch 150 oven controls, the bake and broil relays are both in the circuit whenever either the bake or broil elements are in use.

- True

- False

- The resistance in an oven burner ignitor in the gas models is relatively low when cold, then increases as the ignitor heats.

- True

- False

WARRANTY

Whirlpool ® Gas Range

| LENGTH OF WARRANTY | WHIRLPOOL WILL PAY FOR: |

| FULL ONE YEAR WARRANTY

From Date of Purchase. |

FSP® replacement parts and repair labor to correct defects in materials or workmanship. Service must be provided by an authorized Whirlpool service company. |

| WHIRLPOOL WILL NOT PAY FOR: | |

| A. Service calls to:

1. Correct the installation of the range. 2. Instruct you how to use the range. 3. Replace house fuses or correct house wiring or plumbing. 4. Replace owner-accessible light bulbs. B. Repairs when range is used in other than normal, single family household use. C. Pickup and delivery. Your range is designed to be repaired in the home. D. Damage to your range caused by accident, misuse, fire, flood, acts of God, or use of products not approved by Whirlpool. E. Repairs to parts or systems caused by unauthorized modifications made to the appliance. |

|

Whirlpool ® Electric Range

| LENGTH OF WARRANTY | WHIRLPOOL WILL PAY FOR: |

| FULL ONE-YEAR WARRANTY

From Date of Purchase. |

FSP® replacement parts and repair labor to correct defects in materials or work- manship. Service must be provided by an authorized Whirlpool service company. |

| FULL FIVE-YEAR WARRANTY

From Date of Purchase. |

Ceramic cooktop only; FSP replacement parts and repair labor for CLEANTOP™ ceramic cooktop to the original purchaser of this product.

Whirlpool warrants that: – The ceramic cooktop will not discolor – The ceramic cooktop pattern will not wear off – The rubber seal between the ceramic cooktop and porcelain edge will not crack – The ceramic cooktop will not crack due to thermal shock – The surface units will not burn out |

| WHIRLPOOL WILL NOT PAY FOR: | |

| A. Service calls to:

1. Correct the installation of the range. 2. Instruct you how to use the range. 3. Replace house fuses or correct house wiring or plumbing. 4. Replace owner-accessible light bulbs. B. Repairs when range is used in other than normal, single family household use. C. Pickup and delivery. Your range is designed to be repaired in the home. D. Damage to your range caused by accident, misuse, fire, flood, acts of God, or use of products not approved by Whirlpool. E. Ceramic cooktop only; Repairs to CLEANTOP ceramic cooktop if it has not been cared for as recommended in the Use and Care Guide. F. Repairs to parts or systems caused by unauthorized modifications made to the appliance. |

|

WHIRLPOOL CORPORATION SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

- Some states do not allow the exclusion or limitation of incidental or consequential damages, so this exclusion or limitation may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

- Outside the United States, a different warranty may apply. For details, please contact your authorized Whirlpool distributor or military exchange.

- If you need service first see the “Troubleshooting” section of the Use and Care Guide. After checking “Troubleshooting,” additional help can be found by checking the “Requesting Assistance or Service” section, or by calling our Consumer Assistance Center telephone number, 1-800-253-1301, from anywhere in the U.S.A.

® Registered Trademark/TM of Whirlpool Corporation.

Making your world a little easier.

FAQs Whirlpool Super Capacity 465 Freestanding Gas & Electric Ranges

How should my Whirlpool Super Capacity 465 be cleaned?

The cleaning cycle to begin

Select Clean from the menu.

Choose the cycle time or clean setting you want.

Select Start from the menu.

Allow the range to cool after the cycle is finished, then clear any leftover ashes

What about Whirlpool electric ranges?

Are Whirlpool’s electric ranges up to par? For your baking and culinary needs, Whirlpool manufactures good electric ranges that work well. You can rely on Whirlpool to provide high-quality electric ranges given their lengthy experience in the appliance industry.

How should my Whirlpool gas range be used?

Turning the knob anticlockwise to IGNITE will ignite a match held close to a burner. After the burner has lit, adjust the knob. Important: Keep the airflow around the burner grate edges clear for ventilation and combustion. Burner cap: When using a surface burner, keep the burner cap in place at all times.

How is a Whirlpool Super Capacity 465 oven unlocked?

When using or starting the oven, the door is locked. For one minute, switch off the electricity at the circuit breaker or fuse box before turning it back on. After allowing the oven to cool for 30 to 90 minutes, unlock the door by moving the latch arm to the left.

Exist self-cleaning features in all Whirlpool ovens?

The majority of contemporary Whirlpool ovens offer a self-cleaning oven feature that makes cleaning your oven quick and simple. Your oven is heated to a very high temperature to burn off all the loose food and other debris as part of the self-cleaning process.

Exist self-cleaning features in all Whirlpool ovens?

The majority of contemporary Whirlpool ovens offer a self-cleaning oven feature that makes cleaning your oven quick and simple. Your oven is heated to a very high temperature to burn off all the loose food and other debris as part of the self-cleaning process.

Why won’t my oven from Whirlpool heat up?

Damaged or Broken Bake Element The bake element in your Whirlpool oven may be damaged or broken if the oven won’t even begin to heat up. To begin, look for physical damage by visually evaluating the heating element. If everything appears to be in order, a multimeter test of the element is required.

How can a Whirlpool stove be reset?

Reset the product’s power:

By shutting off the circuit breakers for one (1) minute, you can turn the unit off.

By turning on the circuit breaker, turn on the unit (s).

begin the baking cycle.

For one (1) minute, keep an eye on the oven to make sure the error code doesn’t appear again.

Check the oven’s functionality.

For more Whirlpool Manuals visit ManualsDock