SAFETECH DL714 F Series Dock Leveller

About SafeTech

SAFETECH offers a comprehensive range of services and personal protective equipment to all businesses that require workers to be at heights. The heart of the SAFETECH team is Mr Sudipto Bose, a self-driven businessman who founded SAFETECH on his own with the goal of REDEFINING HEIGHT SAFETY STANDARDS.

Standard Specifications

| Safetech Hydraulic Dock Levellers | |||||

| Model | DL703-F | DL708-F | DL710-F | DL712-F | DL714-F |

| Deck Width | 2110mm | 2110mm | 2110mm | 2110mm | 2110mm |

| Deck Length | 600mm | 2210mm | 2820mm | 3440mm | 4040mm |

| Lip Length | 490mm | 490mm | 490mm | 490mm | 490mm |

| Nominal Overall Travel Up | 350mm | 750mm | 750mm | 1000mm | 1075mm |

| Nominal Overall Travel Down | 75mm | 180mm | 180mm | 180mm | 180mm |

| Nominal Travel Up At 10% Gradient |

60mm |

210mm |

275mm |

335mm |

400mm |

| Nominal Travel Up At 15% Gradient |

N/A |

310mm |

410mm |

500mm |

600mm |

| Static Capacity | 7000kg | 12,500.00kg | |||

| Type of Installation | Pit Mounted | Pit Mounted or Tailgate Recess | |||

| Pit Types available | Pit Mounted- Available on all models

Tailgate Recess- Available on 708, 710, 712 & 714 Step Down – Available on 710 & 714 Only Ezy Pit – Standard -Available on 710 & 714 Only Ezy Pit – Tailgate – Available on 710 & 714 Only |

||||

| Dock Bumpers | Rubber (Standard), Composite (Optional) | ||||

| Pit Surround | Galvanised (Supplied by Safetech, installed by others) | ||||

| Finish | The Dock leveller is shot blasted, primed with a rust-inhibiting primer and finished with two (2) coats of industrial enamel.

Colour – Blue RAL 5010. Dry Film Thickness – 40 microns |

||||

| Toe Guards | Telescopic guards on both sides are painted safety yellow | ||||

| Power pack | 1.1kW 415V 3 Phase 50Hz Mounted to the base frame underneath the deck | ||||

| Controls | Low voltage 24V wall-mounted push button | ||||

| Power Requirements | 415V (3 Phase) 10amp 50Hz outlet in the pit and Isolating switch on the wall by others | ||||

| Operation | Constant Pressure Single Push Button Control for Operation of Deck Platform and Loading Lip. Incorporating Full Hydraulic System with Hydraulic Fail Safe Valve on Deck Cylinder. | ||||

| Dock Levellers is fitted with the Intrinsically Safe Safety Prop | |||||

| The Safety Prop will support both the Lip and Deck and can withstand A 4,500 Kg Moving Load and has a Lockout / Tag-Out Capability. | |||||

| The Safety Prop is activated from above the platform and is a one-man operation to both engage and disengage. | |||||

Introduction

Scope of this Manual

This manual covers the operation of the Dock Leveller after it has been installed and commissioned. Do not attempt to install or commission a Dock Leveller unless you have been trained and authorised by Safetech.

Disclaimer

Although every effort is made to ensure the accuracy, currency and completeness of the information contained in this manual, Safetech does not guarantee, warrant, represent or undertake that the information is correct, accurate or current. Safetech is not liable for any loss, claim, cost or expense of any kind arising in any way whatsoever from the information contained in this manual.

Copyright © 2016

Safetech of 39-45 Della Torre Road, Moe Victoria, 3825, all rights reserved. No part of this document may be reproduced or utilised in any means, by any means, electronic or mechanical, including photocopying, recordings or any information storage or retrieval system, without the express permission from Safetech.

Owner’s Responsibility

To ensure both your safety and the safety of others, and the continued effective operation of your Safetech Dock Leveller, your responsibilities are as follows:

- Before operating the Dock Leveller, please read and ensure you understand both the safety instructions and the operating instructions.

- If you do not fully understand these instructions, contact either Safetech or an authorised Safetech agent for clarification before operating your Dock Leveller.

- The Owner must review the Risk Assessment in this manual.

- Please Note: In the Risk Assessment, a number of items have been flagged as Completed. = No. The Owner must include these hazards in their own operational risk assessment and ensure that action is taken to address the hazard.

- The owner is responsible to ensure all operators have been adequately trained on the safe operation of the Dock Leveller.

- The owner is responsible to ensure that a risk assessment on the Dock Leveller in their operating environment is done.

Safety Instructions

Before operating the dock leveller, please read and ensure you understand both the safety instructions and the operating instructions.

If you do not fully understand these instructions, contact either Safetech or an authorised Safetech agent for clarification before operating your dock leveller.

- Improper operation of this dock leveller may result in serious personal injury. Do not operate unless you have been properly trained and have read, and understand both the safety and operating instructions.

- DO NOT allow any unauthorised access to, or under the dock leveller.

- Ensure all personnel are clear of the boom gate when the boom gate is operating.

- DO NOT allow any person near the dock leveller when it is operating or near a truck when it is reversing toward, or leaving the dock.

- DO NOT exceed the rated capacity as indicated on the serial plate.

- DO NOT allow any equipment on the Dock Leveller when the truck is leaving the dock.

- DO NOT attempt to lift the Dock Leveller with personnel or equipment on the unit.

- DO NOT drive loading equipment (eg forklift) onto the Dock Leveller when the Dock Leveller is in the below cross-traffic position and is NOT resting on the truck. Ensure the load lip rests securely on the truck bed during loading/unloading operations.

- Trucks should be restrained by an effective restraint system during loading/unloading operations to prevent movement of the truck.

- DO NOT use a damaged or broken Dock Leveller.

- DO NOT drive loading equipment close to the edge of the Dock Leveller.

- DO NOT operate Dock Leveller if the height of the truck bed is more than 14% above the cross-traffic position or more than 3% below the cross-traffic position.

- The excessive incline of the Dock Leveller may result in unsafe operating conditions for loading equipment.

- Loading equipment should not exceed 5 kph whilst on the Dock Leveller.

- DO NOT operate Dock Leveller if under the influence of drugs or alcohol.

- If you have an ‘AUTO RETURN TO CROSS TRAFFIC’ model, when the truck departs the dock will automatically return to the ‘cross traffic’ position. You need to :

- Ensure no personnel are in the area of the truck and the dock leveller when the truck departs.

- Do a risk assessment and develop and implement a safe working procedure

- Train your personnel on the safe work procedure

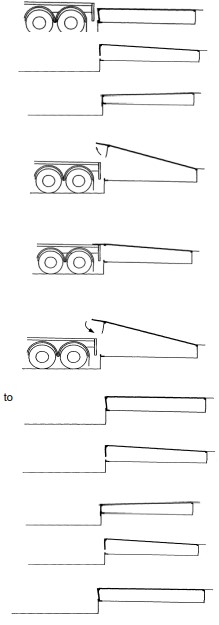

- When not in use the Dock Leveller should be in the cross-traffic position with the lip tucked inside the base frame front angle.

Dock Leveller in cross-traffic position with lip tucked in

- DO NOT enter under the dock leveller for cleaning unless you have been trained and authorised to do so.

- The owner must also do a risk assessment and develop safe work procedures for ergonomically sound cleaning practices.

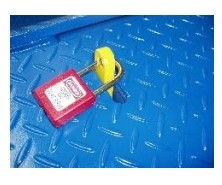

- For routine cleaning, the Dock Leveller must be securely resting on the maintenance prop as per the following instructions, the area must be cordoned off with a suitable safety barrier to prevent access by personnel or equipment and the main power to the Dock Leveller must be isolated by an effective Lockout / Tag out system.

- Clean from outside the dock using a long-handled cleaning device.

- DO NOT spray the electrical system with high-pressure water.

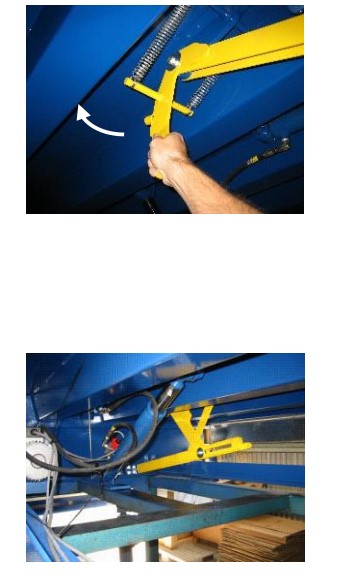

Dock levellers fitted with the Intrinsically Safe Maintenance Prop To Engage the Maintenance Prop:

Engaging the maintenance prop is a one-man operation.

- With the dock leveller in the parked position, stand on top of the dock leveller.

- Insert a screwdriver (approx 250mm long) or similar device through the hole in the deck and push down on the maintenance prop lever. The screwdriver needs to be inserted approximately 40mm. The tension spring will then pull the safety lever down and the maintenance prop will be activated.

- Stand clear of the dock leveller and raise the deck until the lip fully extends. When the deck is fully raised and the lip fully extended, release the dock leveller raise button.

- The lock-out section of the maintenance prop will automatically protrude through the hole in the deck as the deck lowers onto the maintenance prop.

- The maintenance prop should now be automatically engaged with the lip fully supported.

To Safety Release the Maintenance Prop:

- Stand at the front of the dock leveller at ground level. Firmly push back on the release arm until the release arm hits the underside of the deck. Note: When pushing back the release arm by hand take care as the release arm is under spring tension and if not firmly pushed, the arm may pull back under tension and the hand may hit on the maintenance prop. A force of approx 20 kg is required to push the release arm back.

- After activating the release arm stand on top of the deck and remove the padlock from the tongue protruding through the deck. Take care when walking on a raised deck.

- Remove Lock out /Tag out system.

- From the control station fully raise the deck then release the raise button. The maintenance prop will automatically disengage as the deck begins to lower. Lower the deck to the parked position

- The dock leveller is now ready for normal use.

- Maintenance and service on all dock levellers must only be carried out by a person who has been trained and accredited by Safetech or has been trained and authorised by the Owner. A Safetech Service maintenance prop, or equivalent, properly engaged must be used when doing service or maintenance.

- DO NOT enter under the Dock leveller for service or maintenance purposes unless you have been trained and authorised to do service work. A Safetech Service maintenance prop, or equivalent, properly engaged must be used when doing service or maintenance work.

- Maintenance and service on the dock leveller must be done at regular intervals to ensure trouble-free and safe operation. For high cycle or heavy load environments, service should be done every 3 months. For medium or low-cycle environments, service should be done every six months.

- If the dock leveller is not operating correctly or is undergoing maintenance or service work, an effective ‘LOCKOUT / TAG OUT’ procedure must be used.

eg: Lock-out isolating switch with an assigned individual key-padlock and danger tag to prevent the possibility of inadvertent energisation

- DO NOT modify, dismantle or dispose of the Dock Leveller unless you have been trained and authorised to do so.

Static and Dynamic Load Capacities

- To assess the required capacity, all Safetech Dock Levellers have a rated static capacity, which is measured when the Dock Leveller is stowed.

- Safetech Dock Levellers are market leaders in their safe operating dynamic load capacities, which is approximately 65% of the rated static capacity.

- These measurements assume that any forklift or loader does not exceed 5km/hr and the operating grade does not exceed 10%.

- For conditions which exceed these standards, please contact Safetech for your individual requirements.

Safety Instructions

Abide by the requirements defined in the ‘Good Safety Practices’ sign when operating the dock leveller

Good Safety Practices

Operating Instructions

Before operating the Dock Leveller Please read and & ensure you understand Both the Safety Instructions & the Operation Instructions are applicable to your unit. If you do not fully understand these Instructions, contact another Safetech or an Authorised Safetech Agent for clarifications Before the operation of your Dock Leveller.

Caution When access to the Underside of the Dock Leveller Is required for cleaning or any other purpose refers to the Safety Instructions.

Operating Instructions with Single Push Button

WARNING: Do not exceed 14% Gradient on Deck

IMPORTANT: – STAND CLEAR WHEN OPERATING UNIT

- Open the vehicle loading hinge doors, and reverse the vehicle into position against the dock bumpers.

- Press the dock leveller RAISE button until the deck is raised and lip is fully extended.

- Release the RAISE button. The dock leveller will lower until the loading lip rests on the vehicle floor. When unloading, as the vehicle floor raises with decreased load, the deck will automatically adjust upwards to loading height. When loading, as the vehicle floor lowers with increased load, the deck will readjust to the new lowered height.

- PRIOR to the vehicle leaving the dock, press the RAISE button. As the deck raises the lip will lower into the vertical position. HOLD button only until the lip is completely vertical and clear of any obstruction

- Release the RAISE button to allow the deck to float into the cross-traffic position.

- If the dock leveller is below level, to shut away press the RAISE button until the deck lifts to approximately 300mm (12”) above horizontal.

- Release the RAISE button and the dock leveller will return to the cross-traffic position.

NOTE: If the dock leveller has been servicing the vehicle below dock height, follow instructions 6 & 7 to return it to cross traffic position.

Operating Instructions with Independent Lip Control

WARNING: Do not exceed 14% Gradient on Deck

IMPORTANT: -STAND CLEAR WHEN.OPERATING UNIT

- Reverse the vehicle into position against dock bumpers.

- Press and hold the dock leveller “dock raise” button. While the dock leveller is raising, jog the lip out to clear the lip supports using independent lip control. Release the dock leveller “dock raise” button and the dock leveller will lower to the lowered position.

- Open vehicle hinge doors.

- Press the dock leveller raise button until the lip clears the rear of the vehicle. Whilst holding down the “dock raise” button, simultaneously press the “lip raise” button until the lip fully extends.

- Release the “dock raise” button. The dock leveller will lower until the Loading lip rests on the vehicle floor. When unloading, as the vehicle Floor raises with decreased load, the deck will automatically adjust upwards to loading height. When loading, as the vehicle floor lowers with increased load, the deck will readjust to the new lowered height.

- Prior to the vehicle leaving the dock, press the “dock raise” button. As the deck raises the lip will lower into the vertical position. HOLD button only until the lip is completely vertical and clear of any obstruction.

- Release the “dock raise” button to allow the deck to fall to cross traffic position.

- To close vehicle hinge doors, press and hold the dock leveller “dock raise” button. While the dock leveller is raising, jog the lip out to clear the lip supports using independent lip control. Release the dock leveller “dock raise” button and the dock leveller will lower to the lowered position.

- Close the vehicle hinge doors.

- To shut away press the “dock raise” button until the deck raises to approximately 300mm (12”) above horizontal.

- Release the “dock raise” button and the dock leveller will return to the cross traffic position.

Maintenance

Maintenance & Repair Personnel: Safetech Equipment should be serviced and maintained by a qualified Safetech representative. If you require servicing you can entering into a service agreement with Safetech. Please click on the link to obtain the Safetech Service Agreement. http://www.safetech.com.au/safetech-serviceagreement

If this is not possible, then the Owner must:

- Develop & implement a preventive maintenance plan for the unit.

- Create a competency-based training program for servicing the unit.

- Train & authorise personnel on the safe & correct service of the unit.

- Permit only suitably trained & skilled personnel to service the unit.

Planned Maintenance

To prolong the operational life and ensure the safe operation of your Dock Leveller table we recommend regular planned maintenance by Safetech or a Safetech-authorised agent. For high cycle or heavy load environments, service should be done every three (3) months. For medium or low-cycle environments, service should be done every six (6) months. Please contact either Safetech or a Safetech-authorised agent to discuss your maintenance requirements.

Troubleshooting

If, for any reason, your Dock Leveller does not work, check the following:

- Is the power supply switched on?

- Has the Dock Leveller been operated with loads in excess of the stated capacity?

- If the power supply is switched on and the Dock Leveller has not been operated with loads in excess of the stated capacity, and the Dock Leveller does not work, contact an authorised agent to rectify the problem. Damage to the Dock Leveller or lack of prescribed maintenance may result in the Dock Leveller being inoperable.

For Repairs or Services or a Planned Maintenance Program: Contact Safetech at 03 8546 5600

Warranty

Refer to Safetech’s complete Terms of Sale and Warranty at http://www.safetech.com.au/termssale-warranty/

Safetech’ Divisions

| Head Office | |

| Head Office – Moe, Victoria | Address: 39-45 Della Torre Road, Moe, Victoria, 3825 Postal Address: PO Box 360, Moe, Victoria, 3825 Phone: 1800 674 566

Email: sales@safetech.com.au |

| Service | |

| Service Enquiries | Phone: 03 8546 5600

Email: service@safetech.com.au |

| Sales offices | |

| Victoria | Address: 1a/21 Lionel Road Mt Waverley VIC 3149 |

Risk Management

Risk Assessment:

| Safetech Hydraulic Dock Leveller | |||||||

|

Hazard No |

Hazard / Risk |

Probability |

Consequence |

Control |

Risk control implementation | ||

| Responsibility of: | Completed

? |

||||||

| 1 | Inadequate information supplied to enable the safe installation of the Dock leveller. | Possible | Catastrophic | · Provide Installation Manuals to Installers that have all the necessary information to safely install the unit and ensure that it operates correctly. | Product designer | Yes | |

| 2 | Untrained personnel installing the equipment could result in injury to personnel and damage to equipment. | Possible | Catastrophic | · Read & understand the Installation manual.

· Create a competency-based training program for installation personnel. · Train & authorise installers on the safe & correct installation of the unit using a Safetech Service maintenance prop or equivalent. · Only suitably trained & skilled personnel to install the unit. |

Installer | Yes if Safetech.

No, if not Safetech. |

|

| 3 | Inadequate information supplied to enable the safe operation of the Dock Leveller could result in damage to equipment and injury to personnel. | Possible | Catastrophic | · Provide Owners Manuals, Operating Instructions & Signage to the Owner that has all the necessary information for people to safely operate, maintain in good condition during its operating life and then finally dispose of the equipment after its useful life. | Product designer | Yes | |

| 4 | Untrained operators using the Dock Leveller could result in damage to equipment and injury to personnel. | Possible | Catastrophic | · Read & understand the Owner’s Manual.

· Create an adequate competency-based training program for operators · Train & authorise operators on the safe & correct use of the unit. · Only trained & authorised personnel to use Dock leveller. |

Owner | No | |

| 5 | Untrained personnel attempting to service or do maintenance on a Dock Leveller could result in damage to equipment or injury to personnel.

Also refer to Hazard Nos 15, 16 & 17 (Hydraulic & Electrical) |

Possible | Catastrophic | · Owner to ensure only Safetech-trained and accredited people carry out service or maintenance.

OR

· Develop & implement a preventive maintenance plan for the unit. · Create a competency-based training program for servicing the unit. · Train & authorise personnel on the safe & correct service of the unit using a Safetech Service maintenance prop or equivalent. · Only suitably trained & skilled personnel to service the unit. |

Owner | No |

| 6 | Untrained personnel modifying the Dock Leveller could result in injury to personnel and damage to equipment. | Possible | Catastrophic | · Owner to ensure only Safetech-trained and accredited people modify the unit.

OR

· Develop & implement a plan for modifying the unit. · Create a competency-based training program for modifying the unit. · Train & authorise personnel on the safe & correct modification of the unit using a Safetech Service maintenance prop or equivalent. · Only suitably trained & skilled personnel to modify the unit. |

Owner | No |

| 7 | Untrained people dismantling the Dock Leveller could result in damage to equipment and injury to personnel. | Possible | Catastrophic | · Owner to ensure only Safetech-trained and accredited people dismantle the unit.

OR

· Develop & implement a plan for the dismantling of the unit. · Create a competency-based training program for personnel dismantling of the unit. · Train & authorise personnel on the safe & correct dismantling of the unit using a Safetech Service maintenance prop or equivalent. · Only suitably trained & skilled personnel to dismantle the unit. |

Owner | No |

| 8 | Untrained people disposing of the Dock Leveller could result in damage to equipment, injury to personnel and non-compliance to regulations. | Possible | Catastrophic | · Owner to ensure only Safetech-trained and accredited people dispose of the unit.

OR

· Develop & implement a plan for the disposal of the unit. · Create a competency-based training program for personnel disposing of the unit. · Train & authorise personnel on the safe & correct disposal of the unit using a Safetech Service maintenance prop or equivalent. · Only suitably trained & skilled personnel to dispose of the unit. |

Owner | No |

| 9 | Inadequate service & maintenance of the unit results in unsafe operation and potential injury to personnel. | Possible | Catastrophic | · Contact Safetech for the regular servicing of your Dock leveller. (3 monthly service intervals for a heavy workload unit & 6-month service intervals for a low workload unit.)

OR

· Develop & implement a preventive maintenance plan for the unit. · Create a competency-based training program for servicing the unit. · Train & authorise personnel on the safe & correct service of the unit using a Safetech Service maintenance prop or equivalent. · Only suitably trained & skilled personnel to service the unit. |

Owner | No |

| 10 | Unknown safety hazards are existing in the area due to unknown local practices or the impact of the Dock Leveller in the area could result in injury to personnel and damage to equipment. | Possible | Catastrophic | · Owner must ensure that a risk assessment on the unit in their operating environment is done | Owner | No |

| 11 | When the Dock Leveller is above the cross traffic position there is a risk of a shear/crush injury between the Dock Leveller sides & the dock pit edge. | Possible | Major | · Side Safety Guarding fitted to the sides of the Dock Leveller to prevent foot/hand intrusion.

· Provide clear instructions in the Owner’s manual that specify that the unit must only be operated when all personnel are clear of the Dock Leveller area. |

Designer | Yes |

| · Ensure that the unit is only operated when all personnel are clear of the dock area.

· Include this hazard in your risk assessment. |

Owner | No | ||||

| 12 | If side safety guards are missing or damaged there is a risk of a shear/crush injury between the Dock Leveller sides & the dock pit edge. | Possible | Major | · Provide clear instructions in the Owner’s manual that specify that the unit must only be operated when all personnel are clear of the Dock Leveller

area. |

Designer | Yes |

| · Ensure that the unit is only operated when all personnel are clear of the dock area.

· Include this hazard in your risk assessment. |

Owner | No | ||||

| 13 | When the Dock Leveller is lowered onto the truck bed there is a risk of a shear/ crush injury at the contact point between the load lip and the vehicle floor. | Possible | Major | · Provide clear instructions in the Owner’s manual that specify that the unit must only be operated when all personnel are clear of the Dock Leveller area. | Designer | Yes |

| · Ensure that the unit is only operated when all personnel are clear of the dock & truck.

· Include this hazard in your risk assessment. |

Owner | No |

| 14 | With one-button operation, when the raise button is released the Dock Leveller automatically lowers to a resting point (either truck bed or lowered position), and there is a risk of a shear /crush injury at any contact point. | Unlikely | Major | · Provide clear instructions in the Owner’s manual that specify that the unit must only be operated when all personnel are clear of the Dock Leveller area. | Designer | Yes |

| · Ensure that the unit is only operated when all personnel are clear of the dock area.

· Include this hazard in your risk assessment. |

Owner | No | ||||

| 15 | When Dock Leveller is being moved to the cross traffic position or fully lowered position there is a risk of a shear/crush injury at the pivot edge of the Dock Leveller and load lip. | Unlikely | Major | · Provide clear instructions in the Owner’s manual that specify that the unit must only be operated when all personnel are clear of the Dock Leveller

area. |

Designer | Yes |

| · Ensure that the unit is only operated when all personnel are clear of the dock area.

· Include this hazard in your risk assessment. |

Owner | No | ||||

| 16 | Electrical Hazard (: 240V and 3 phase 415V) created if the power cable is damaged could result in shock, burns or seizure to personnel. | Rare | Catastrophic | · Wiring to relevant Aust. Stds. & to the requirements of the Chief Electrical Inspector | Designer | Yes |

| 17 | Operators in contact with 3 phase 415V supply voltage could suffer shock, burns or seizure. | Rare | Catastrophic | · 3 Phase, 415V supply outlet mounted to the rear of the pit to be inaccessible to unauthorised persons.

· Supply to outlet run in protective conduit. |

Designer | Yes |

| · Wiring complies with all Relevant Standards and requirements. | Installer | Yes if Safetech.

No if not Safetech. |

||||

| 18 | Hydraulic failure allowing the collapse of the unit can result in injury to personnel under or near Dock Leveller. | Rare | Major | · Fit a Velocity Control device to prevent the sudden collapse of the unit, and ensure the specifications of manufacture comply with relevant standards.

· Provide clear instructions in the Owner’s manual that specify that the unit must only be operated when all personnel are clear of the Dock Leveller area. · Provide clear instructions in the Owner’s manual that specify the requirements for access under the unit. |

Designer | Yes |

| · Develop & implement a safe work procedure for cleaning under the dock.

· Include this hazard in your risk assessment. |

Owner | No | ||||

| 19 | Load Lip collapse due to excessive load placed on the lip could result in injury to personnel and damage to equipment. | Rare | Catastrophic | · Provide clear instructions in the Owner’s manual on load limits. | Designer. | Yes |

| · Do not overload the Dock Leveller.

· Include this hazard in your risk assessment. |

Owner. | No |

| 20 | Structural damage to Dock Leveller if the dock is subjected to loads greater than the specified capacity could result in damage to equipment and injury to personnel. | Rare | Catastrophic | · Provide clear instructions in the Owner’s manual on load limits. | Designer | Yes |

| · Do not overload the Dock Leveller.

· Include this hazard in your risk assessment. |

Owner | No | ||||

| 21 | Damage to the Power Pack and/or Control Box could result in injuries to personnel from exposure to live power and equipment failure. | Rare | Catastrophic | · Install the Powerpack and control box as specified by the Designer. | Installer | Yes if Safetech.

No if not Safetech. |

| 22 | Unauthorised access to the dock leveller could result in injury to personnel and damage to equipment. | Possible | Catastrophic | · Include this hazard in your risk assessment. | Owner | No |

| 23 | Material handling equipment or personnel on Dock Leveller when the truck departs could result in injury to personnel or damage to equipment. | Possible | Major | · Provide clear instructions in the Owner’s manual that specify that Dock Leveller must be clear of personnel & equipment when the truck departs. | Designer | Yes |

| · Ensure that the Dock Leveller is clear of all equipment & personnel when the truck departs.

· Include this hazard in your risk assessment. |

Owner | No | ||||

| 24 | Operators attempting to lift the Dock Leveller with equipment or personnel on the Dock Leveller could result in injury to personnel and damage to equipment. | Possible | Major | · Provide clear instructions in the Owner’s manual that specify that Dock Leveller must be clear of personnel & equipment when operating. | Designer | Yes |

| · Ensure that the equipment & personnel are clear of Dock Leveller when the unit is operating.

· Include this hazard in your risk assessment. |

Owner | No | ||||

| 25 | When cleaning under Dock Leveller and another person operating the dock there is a risk of a shear/crush injury to the person under the dock. | Possible | Catastrophic | · Provide clear instructions in the Owner’s manual that specifies the requirements for cleaning under the Dock Leveller. | Designer | Yes |

| · Ensure that procedures for safe & effective cleaning under Dock Leveller are developed & implemented.

· Include this hazard in your risk assessment. |

Owner | No | ||||

| 26 | Loading equipment driven onto Dock Leveller when the Dock leveller is in the lowered position and not resting on a truck may cause loading | Possible | Catastrophic | · Provide clear instructions in the Owner’s manual that specifies not to drive loading equipment onto Dock Leveller when the unit is in the lowered position and not resting on the truck bed. | Designer | Yes |

| equipment to go out of control resulting in injury to personnel and damage to equipment. | · Ensure that loading equipment is not driven onto Dock Leveller when Dock Leveller is in the lowered position and not resting on a truck.

· Include this hazard in your risk assessment. |

Owner | No | |||

| 27 | If auto return to cross traffic is installed, when the truck departs dock automatically returns to cross traffic position which could result in injury to personnel standing close to the Dock Leveller | Possible | Catastrophic | · Provide clear instructions in the Owner’s manual that specifies the operation of automatic return to cross traffic. | Designer | Yes |

| · Ensure Dock Leveller is clear of personnel when operating.

· Include this hazard in your risk assessment. |

Owner | No | ||||

| 28 | Trucks entering or leaving the dock area to create a traffic hazard that could result in injury to personnel or damage to equipment. | Possible | Catastrophic | · Develop & implement procedures for traffic management in the docking area.

· Include this hazard in your risk assessment. |

Owner | No |

| 29 | If the truck is not restrained during loading/unloading truck may move to result in injury to personnel or damage to equipment. | Possible | Catastrophic | · Provide clear instructions in the Owner’s manual that specify that the truck should be restrained during loading/unloading operations. | Designer | Yes |

| · The Owner must use suitable restraining equipment and/or procedures to ensure that the truck does not move.

· Include this hazard in your risk assessment. |

Owner | No | ||||

| 30 | Use of a damaged or broken Dock Leveller could result in injury to personnel and further damage to equipment. | Possible | Catastrophic | · Provide clear instructions in the Owner’s manual that specify not to use a damaged or broken Dock Leveller. | Designer | Yes |

| · Ensure regular service is carried out.

· If damaged, use an effective Lockout/Tag out system and arrange for repair. · Include this hazard in your risk assessment. |

Owner | No | ||||

| 31 | If the load lip does not rest securely on the truck bed, the Dock Leveller may fall under the load resulting in injury to personnel & damage to equipment. | Possible | Catastrophic | · Provide adequate instruction in Owner’s manual that specifies load lip should rest securely on the truck bed. | Designer | Yes |

| · Ensure that the load lip is resting securely on the truck bed before placing a load on the unit.

· Include this hazard in your risk assessment. |

Owner | No | ||||

| 32 | If the truck bed is too high or too low, unsafe loading conditions may occur resulting in injury to personnel or damage to equipment. | Possible | Catastrophic | · Provide adequate instruction in Owner’s manual | Designer | Yes |

| · Ensure that Dock Leveller is not operated if a truck bed is too high or too low.

· Include this hazard in your risk assessment. |

Owner | No |

| 33 | The excessive incline on Dock Leveller may result in unsafe forklift operating conditions | Possible | Major | · Provide adequate instruction in Owner’s manual | Designer | Yes |

| · Include this hazard in your risk assessment. | Owner | No | ||||

| 34 | If loading equipment is operated too close to the edge of the Dock Leveller the loading equipment may become unstable and go out of control. | Possible | Catastrophic | · Include this hazard in your risk assessment. | Owner | No |

| 35 | Operation of the Dock Leveller may not be controlled if the operator is under the influence of drugs or alcohol and could result in injury to personnel and damage to equipment. | Possible | Catastrophic | · Include this hazard in your risk assessment. | Owner | No |

| 36 | High-pressure water sprayed on the electrical boxes or control panel may result in electrical faults and potential electrical shock to personnel. | Unlikely | Catastrophic | · Provide adequate instructions in Owner’s manual. | Designer | Yes |

| · Do not spray high-pressure water on electrical boxes or control panels.

· Include this hazard in your risk assessment. |

Owner | No | ||||

| 37 | When reversing up to the Dock Leveller truck may hit Dock Leveller resulting in damage to equipment. | Possible | Minor | · Provide adequate instructions in Owner’s manual. | Designer | Yes |

| · Ensure the truck does not make contact with the Dock leveller.

· Include this hazard in your risk assessment. |

Owner | No | ||||

| 38 | Forklift speeds exceeding 5 kph result in high impact to the Dock Leveller resulting in damage to equipment. | Possible | Minor | · Provide adequate instructions in Owner’s manual. | Designer | Yes |

| · Ensure forklift speed does not exceed 5 kph.

· Include this hazard in your risk assessment. |

Owner | No | ||||

| 39 | If manual maintenance prop fitted, raising the maintenance prop whilst under the Dock Leveller may result in injury to personnel. | Possible | Catastrophic | · Provide clear instructions in the owner’s manual for engaging maintenance prop | Designer | Yes |

| · Ensure safety instructions for engaging maintenance prop are adhered to.

· Include this hazard in your risk assessment. |

Owner | No |

| 40 | If a hydraulic boom gate is fitted, there is a risk of injury to personnel standing under or close to the boom gate or boom. | Possible | Catastrophic | · Design to incorporate

– a pressure limiting valve so that the boom gate will stop if light contact is made.

– flow control valves to limit the velocity of the boom gate.

– solenoid check valves fitted to the cylinder to prevent the sudden collapse of the gate in case of hydraulic failure.

· Design to incorporate an 85 mm gap between boom gates to eliminate shear/crush point and a 50 mm gap between boom gate & boom to eliminate shear/crush point. · Provide a warning sign near the boom gate. · Provide clear instructions in Owner’s manual to stand clear when the boom gate operating |

Designer | Yes |

| · Include this hazard in your risk assessment. | Owner | No | ||||

| 41 | If a hydraulic boom gate is fitted, there is a risk of injury to personnel standing under or close to the boom gate or boom. | Possible | Catastrophic | · Design to incorporate

– a pressure limiting valve so that the boom gate will stop if light contact is made.

– flow control valves to limit the velocity of the boom gate.

– solenoid check valves fitted to the cylinder to prevent the sudden collapse of the gate in case of hydraulic failure. · Design to incorporate an 85 mm gap between boom gates to eliminate shear/crush point and a 50 mm gap between boom gate & boom to eliminate shear/crush point. · Provide a warning sign near the boom gate. · Provide clear instructions in Owner’s manual to stand clear when the boom gate operating |

Designer | Yes |

| · Include this hazard in your risk assessment. | Owner | No | ||||

| 42 | If a manual boom gate is fitted, when the boom gate is being operated, there is a risk of injury to personnel standing under or near the boom gate or boom. |

Possible |

Major |

· Design to incorporate a system to control lowering speed using gas air struts | Designer | Yes |

|

· Include this hazard in your risk assessment. |

Owner |

No |

| 43 | If a manual boom gate is fitted, there is a possibility of damage to the gas air strut. This might cause the booms to fall. |

Possible |

Major |

· Gas struts enclosed within the boom gate structure thus removing the risk of damage | Designer | Yes |

| · Gas struts to have regular maintenance inspection.

· Include this hazard in your risk assessment. |

Owner | No | ||||

| 44 | If Dock Leveller is fitted with an intrinsically safe maintenance prop, incorrect/uncontrolled operation of the maintenance prop release arm could result in a crush injury. | Possible | Catastrophic | · Provide clear instructions in the owner’s manual for the operation of the release arm. | Designer | Yes |

| · Ensure safety instructions for the operation of the release arm are adhered to.

· Include this hazard in your risk assessment. |

Owner | No | ||||

| 45 | If the Dock leveller is fitted with an intrinsically safe maintenance prop, the threaded bolts holding the maintenance prop could break causing the dock leveller to lower. This could result in a shear/crush injury. | Possible | Catastrophic | · Fit a Velocity Control device to prevent the sudden collapse of the unit, and ensure the specifications of manufacture comply with relevant standards.

· Provide clear instructions in the Owner’s manual that specify the requirements for access under the unit. |

Designer | Yes |

| · Develop & implement a safe work procedure for cleaning under the dock.

· Include this hazard in your risk assessment. |

Owner | No | ||||

| 46 | If Dock Leveller is fitted with an intrinsically safe maintenance prop, if the arm of the maintenance prop that supports the lip breaks, the lip will fall which could possibly result in injury to personnel. | Possible | Catastrophic | · Provide clear instructions in the Owner’s manual that specify the requirements for access under the unit. | Designer | Yes |

| · Develop & implement a safe work procedure for cleaning under the dock.

· Include this hazard in your risk assessment. |

Owner | No | ||||

| 47 | If the Dock Leveller is fitted with an intrinsically safe maintenance prop, if the springs on the maintenance prop release arm break, part of the spring could be forcibly propelled and could possibly cause injury to personnel. | Possible | Major | · Include this hazard in your risk assessment. | Owner | No |

Risk Matrix

Risk = Probability (likelihood) x consequence Risk score is calculated by multiplying the points assigned to the probability (likelihood) by the points assigned to the consequence. A risk score is indicative of if action is required to reduce the risk, and when action is to be done.

| Consequence | ||||||||

| Catastrophic | Major | Moderate | Minor | Insignificant | ||||

| Death | Extensive injuries- Amputation | Medical treatment – Doctor | Minor-First Aid | No Injuries | ||||

| Points | 40 | 15 | 7 | 3 | 1 | |||

| Likelihood | Almost Certain | Expected to occur in most circumstances | 100 | 4000 | 1500 | 700 | 300 | 200 |

| Likely | Probably occur in many circumstances | 36 | 1440 | 540 | 252 | 108 | 36 | |

| Possible | Might occur at some time | 9 | 360 | 135 | 63 | 27 | 9 | |

| Unlikely | Could occur at some time | 2 | 80 | 30 | 14 | 6 | 2 | |

| Rare | May occur in exceptional circumstances | 1 | 40 | 15 | 7 | 3 | 1 | |

Risk Score Rating:

| Risk Score

(=Probability points consequence points) |

Risk Rating | Action |

| More than 320 | Very High | Immediate |

| 160-320 | High | Prompt |

| 70-160 | Significant | Correction required |

| 40-70 | Moderate | Attention is needed |

| Less than 40 | Low | Perhaps acceptable |

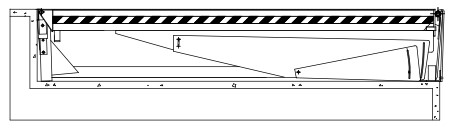

Drawings

| Attachment 1 | As-Built General Arrangement Drawings |

| Attachment 2 | Electrical Schematics |

FAQs SAFETECH DL714 F Series Dock Leveller

What is a dock leveller?

A dock leveller is a hydraulic or mechanical platform that bridges the gap between a loading dock and a trailer bed, allowing forklifts and other equipment to move freely between them.

What are the features of the Safetech DL714 F Series Dock Leveller?

The Safetech DL714 F Series Dock Leveller is a hydraulic dock leveller that comes with various features such as a steel tread plate deck, adjustable spring counterbalance, single-acting hydraulic cylinders, and a weather-resistant control box.

What is the weight capacity of the Safetech DL714 F Series Dock Leveller?

The weight capacity of the Safetech DL714 F Series Dock Leveller ranges from 6,000 to 10,000 pounds, depending on the model chosen.

What is the maximum height range of the Safetech DL714 F Series Dock Leveller?

The maximum height range of the Safetech DL714 F Series Dock Leveller is 12 inches above and below dock level.

How is the Safetech DL714 F Series Dock Leveller installed?

The Safetech DL714 F Series Dock Leveller is typically installed by bolting it to the loading dock using anchor bolts. Professional installation is recommended.

What are the benefits of using the Safetech DL714 F Series Dock Leveller?

The benefits of using the Safetech DL714 F Series Dock Leveller include improved safety, increased efficiency, reduced material handling costs, and greater productivity.

Can the Safetech DL714 F Series Dock Leveller be customized to fit specific needs?

Yes, the Safetech DL714 F Series Dock Leveller can be customized to fit specific needs, including different weight capacities and sizes.

Is regular maintenance required for the Safetech DL714 F Series Dock Leveller?

Yes, regular maintenance is required to ensure the safe and efficient operation of the Safetech DL714 F Series Dock Leveller. It is recommended to have a professional technician perform maintenance and inspections on a regular basis.

For more manuals by SAFETECH, Visit Manualsdock

[embeddoc url=”https://manualsdock.com/wp-content/uploads/2023/03/SAFETECH-DL714-F-Series-Dock-Leveller.pdf” download=”all”]