Maytag MVWB880BW Washer

About Maytag

Maytag is a brand of home appliances, including washing machines, dryers, dishwashers, refrigerators, and ranges. The brand is known for its durable and reliable products, with many models featuring a 10-year limited warranty on certain parts.

Maytag is a subsidiary of Whirlpool Corporation, one of the largest appliance manufacturers in the world. Maytag appliances are available for purchase through a variety of retailers, both online and in-store.

WASHER SAFETY

SAFETY INSTRUCTIONS

TOOLS AND PARTS

Gather the required tools and parts before starting installation.

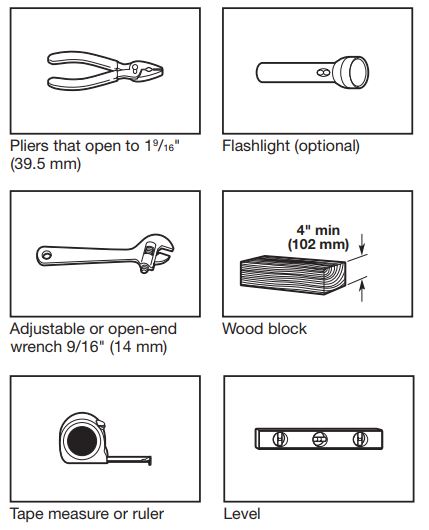

Tools needed:

Parts supplied (located in the washer basket):

Parts needed (Not supplied with washer) :

To order, please refer to the phone number or website on the back page of your “Use and Care Guide.”

- 8212656RP 10 ft. (3.0 m) Inlet hose, Black EPDM (2 pack)

- 8212641RP 5 ft. (1.5 m) Inlet hose, Black EPDM (2 pack)

- 8212646RP 4 ft. (1.2 m) Inlet hose, Black EPDM (2 pack)

- 8212545RP 5 ft. (1.5 m) Inlet hose, Red and Blue EPDM (2 pack)

- 8212487RP 5 ft. (1.5 m) Nylon braided inlet hose (2 pack)

- 8212638RP 6 ft. (1.8 m) Nylon braided inlet hose, space-saving 90° elbow, hyper-blue steel couplings (2 pack)

- 8212637RP 6 ft. (1.8 m) Inlet hose, Black EPDM, space-saving 90° elbow, hyper-blue steel couplings (2 pack)

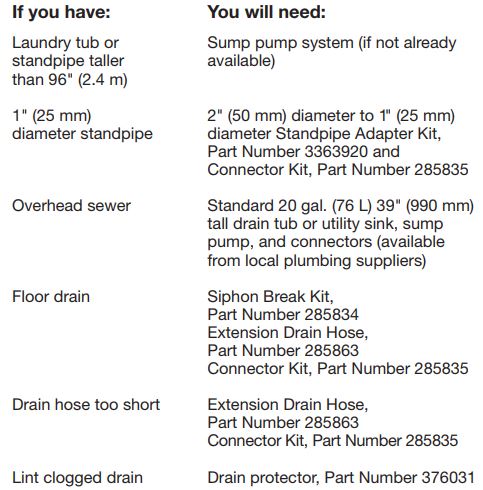

Alternate parts (Not supplied with washer) :

Your installation may require additional parts. To order, please refer to the phone number or website on the back page of your “Use and Care Guide.”

LOCATION REQUIREMENTS

Select a proper location for your washer to improve performance and minimize noise and possible “washer walk.” Install your washer in a basement, laundry room, closet, or recessed area.

Proper installation is your responsibility.

You will need:

- A water heater is set to deliver 120°F (49°C) water to the washer.

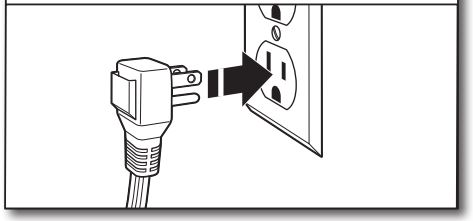

- A grounded electrical outlet is located within 4 ft. (1.2 m) of where the power cord is attached to the back of the washer. See “Electrical Requirements.”

- Hot and cold water faucets located within 3 ft. (900 mm) of the hot and cold water fill valves, and water pressure of 20–100 psi (138–690 kPa) for best performance.

- Level floor with a maximum slope of 1″ (25 mm) under the entire washer. Installing the washer on the carpet is not recommended.

- A sturdy floor to support the washer weight (washer, water, and load) of 315 lbs (143 kg).

IMPORTANT:

Do not operate, install, or store the washer where it will be exposed to water, weather, or at temperatures below 32° F (0° C). Some water can remain in the washer and can cause damage in low temperatures. See your “Use and Care Guide” for information on winterizing.

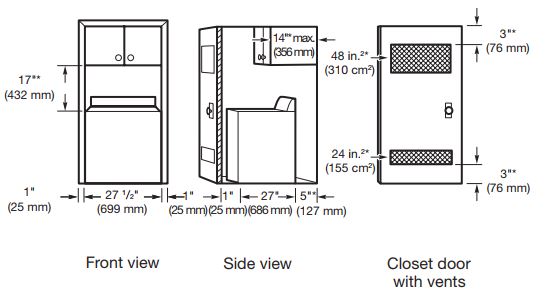

Spacing for the recessed area or closet installation

All dimensions show recommended spacing allowed, with tested spacing of 0″ (0 mm) clearance on sides.

- Additional spacing should be considered for ease of installation and servicing.

- Additional clearances might be required for wall, door, and floor moldings.

- Additional spacing should be considered on all sides of the washer to reduce noise transfer.

- For closet installation, with a door, minimum ventilation openings in the top and bottom of the door are required. Louvered doors with equivalent ventilation openings are acceptable.

- Companion appliance spacing should also be considered.

DRAIN SYSTEM

Drain system can be installed using a floor drain, wall standpipe, floor standpipe, or laundry tub. Select the method you need.

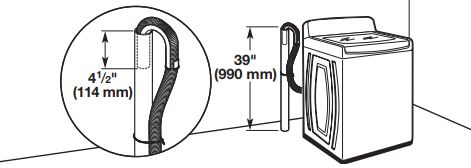

Floor standpipe drain system

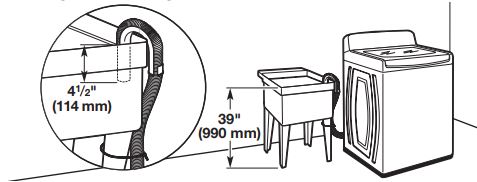

Minimum diameter for a standpipe drain: 2″ (51 mm). Minimum carry-away capacity: 17 gal. (64 L) per minute. Top of standpipe must be at least 39″ (990 mm) high; install no higher than 96″ (2.4 m) from the bottom of the washer. If you must install higher than 96″ (2.4 m), you will need a sump pump system.

Wall standpipe drain system

See requirements for floor standpipe drain system.

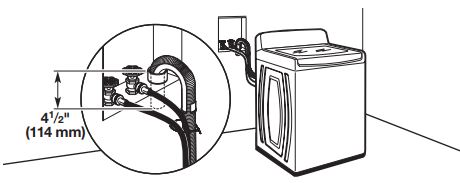

Floor drain system

The floor drain system requires a Siphon Break Kit (Part Number 285834), 2 Connector Kits (Part Number 285835), and an Extension Drain Hose (Part Number 285863) that may be purchased separately. To order, please see toll-free phone numbers in your “Use and Care Guide.” Minimum siphon break: 28″ (710 mm) from the bottom of the washer. (Additional hoses may be needed.)

Laundry tub drain system

Minimum capacity: 20 gals. (76 L). The top of the laundry tub must be at least 39″ (990 mm) above the floor; install no higher than 96″ (2.4 m) from the bottom of the washer.

IMPORTANT:

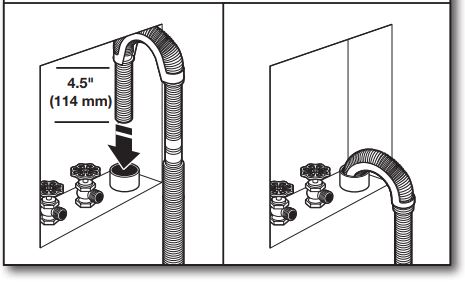

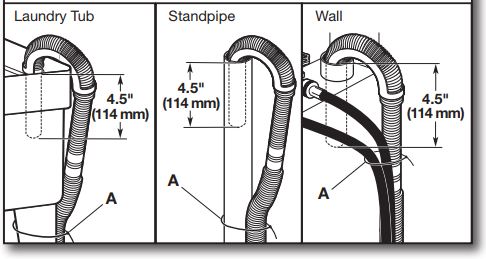

To avoid siphoning, no more than 4 1 ⁄ 2 ” (114 mm) of drain hose should be inside the standpipe or below the top of the wash tub. Secure the drain hose with a cable tie.

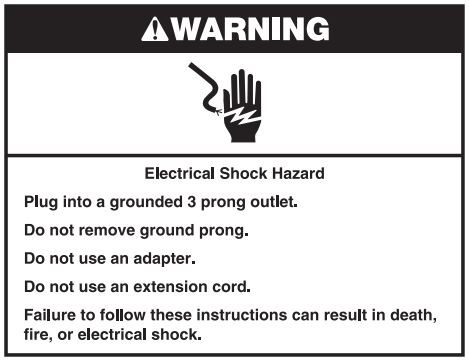

ELECTRICAL REQUIREMENTS

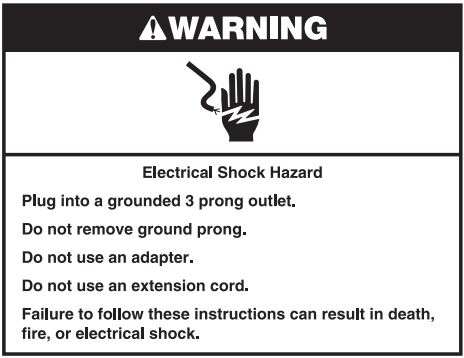

- A 120 volt, 60 Hz., AC only, 15- or 20-amp, fused electrical supply is required. A time-delay fuse or circuit breaker on a separate circuit serving only this washer is recommended

- This washer is equipped with a power supply cord having a 3-prong grounding plug.

- To minimize possible shock hazards, the cord must be plugged into a mating, 3-prong, grounding-type outlet, grounded in accordance with local codes and ordinances. If a mating outlet is not available, it is the personal responsibility and obligation of the customer to have the properly grounded outlet installed by a qualified electrician.

- If codes permit and a separate ground wire is used, it is recommended that a qualified electrician determine that the ground path is adequate.

- Do not ground to a gas pipe.

- Check with a qualified electrician if you are not sure the washer is properly grounded.

- Do not have a fuse in the neutral or ground circuit.

GROUNDED INSTRUCTIONS

INSTALLATION INSTRUCTIONS

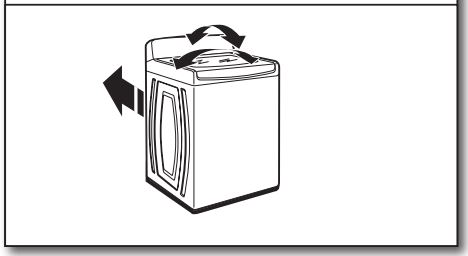

Before you start: remove shipping materials. It is necessary to remove all shipping materials for proper operation and to avoid excessive noise from the washer.

NOTE:

To avoid floor damage during installation, set the washer onto cardboard before moving it across the floor.

IMPORTANT:

- Be sure the foam shipping base has been removed from the bottom of the washer as directed in the “Remove Shipping Base and Packing Ring” section.

- If the foam shipping base has not been removed, be sure the lid is secured with tape before laying the washer on its back.

- Removing the foam shipping base is necessary for proper operation.

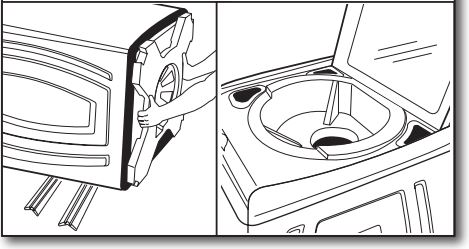

REMOVE THE SHIPPING BASE AND PACKING RING

- Remove the shipping base and packing ring

Place cardboard supports from the shipping carton on the floor behind the washer for support. Secure the lid with tape. Using two or more people, tip the washer onto its back and place it on cardboard supports. Remove foam shipping base. Then, set the washer back upright, and remove the tape from the lid so that you can open the lid and remove the foam packing ring from the washer tub.

NOTE: Keep the foam packing ring in case you need to move the washer in the future

CONNECT DRAIN HOSE

IMPORTANT:

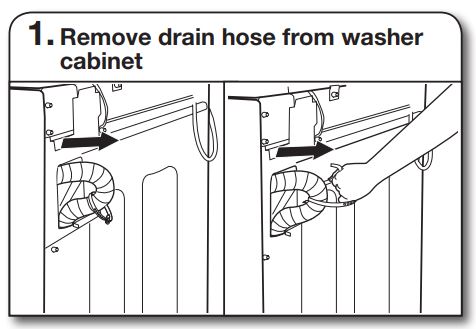

Proper connection of the drain hose helps to avoid water leakage and damage to your floors. The drain hose is connected to your washer and is stored inside the washer cabinet

- Remove drain hose from washer cabinet

Gently pull the hose out of the back of the washer cabinet from the top until the end emerges.

IMPORTANT: Do not force the excess drain hose back into the rear of the washer. - Connect the drain hose form

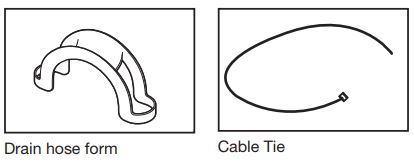

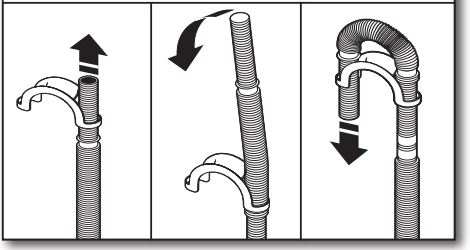

For a laundry tub or standpipe drain, connect the drain hose form. For a floor drain, do not install a drain hose form. You may need alternate parts with separate directions. See “Tools and Parts” to determine what you may need. Feed the hose into one end of the form. Bend the hose and feed through another side, anchoring form on smooth sections of the hose. The hose must extend 4.5″ (114 mm) beyond the form.

For a laundry tub or standpipe drain, connect the drain hose form. For a floor drain, do not install a drain hose form. You may need alternate parts with separate directions. See “Tools and Parts” to determine what you may need. Feed the hose into one end of the form. Bend the hose and feed through another side, anchoring form on smooth sections of the hose. The hose must extend 4.5″ (114 mm) beyond the form. - Place the drain hose in the standpipe

Place the hose into the standpipe (shown in the picture) or over the side of the laundry tub.

IMPORTANT: To keep drain water from going back into the washer:- Do not force the excess drain hose into the standpipe. The hose should be secure but loose enough to provide a gap for air.

- Do not lay an excess hose on the bottom of the laundry tub.

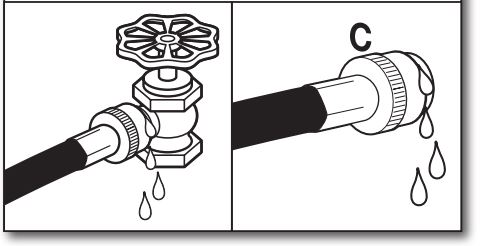

CONNECT INLET HOSES

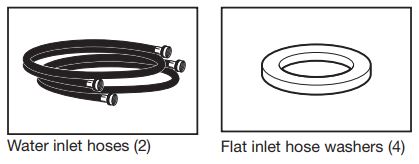

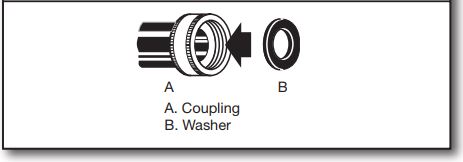

- Insert new flat washers

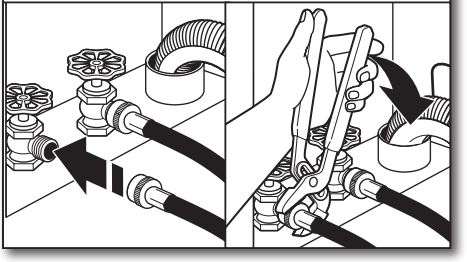

IMPORTANT: To avoid leaks, check that your water inlet hoses have flat washers at both ends. The washer must be connected to water faucets with new inlet hoses with flat washers (not provided). Do not use old hoses. Do not use hoses without washers. - Connect inlet hoses to water faucets

Make sure the washer basket is empty. Attach the hose labeled hot to a hot water faucet. Screw on the coupling by hand until it is seated on the washer. Use pliers to tighten couplings an additional two-thirds turn. Repeat this step with the hose labeled cold for the cold water faucet. Both hoses must be connected for the washer to work properly.

IMPORTANT: Do not overtighten or use tape or sealants on the valve when attaching it to faucets or washers. Damage can result.

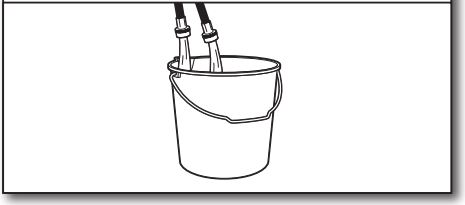

HELPFUL TIP: Make note of which hose is connected to hot water to help in attaching hoses to the washer correctly. - Clearwater lines

Run water for a few seconds through hoses into a laundry tub, drainpipe, or bucket to avoid clogs. Water should run until clear. Check the temperature of the water to make sure that the hot water hose is connected to the hot water faucet and the cold water hose is connected to the cold water faucet. - Connect inlet hoses to the washer

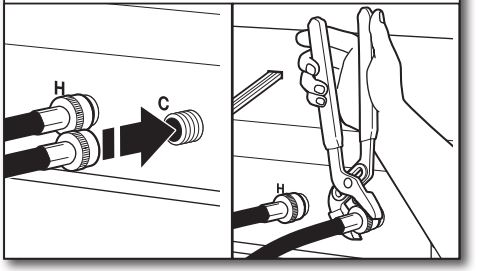

Attach the hot water hose to the hot water inlet valve. Screw coupling by hand until it is snug. Use pliers to tighten couplings an additional two-thirds turn. Repeat with cold water inlet valve. Both hoses must be connected for the washer to work properly.

Attach the hot water hose to the hot water inlet valve. Screw coupling by hand until it is snug. Use pliers to tighten couplings an additional two-thirds turn. Repeat with cold water inlet valve. Both hoses must be connected for the washer to work properly.

IMPORTANT: Do not overtighten or use tape or sealants on the valve when attaching it to faucets or washers. Damage can result.

NOTE: To reduce the risk of hose failure, replace the hoses every 5 years. Record hose installation or replacement dates for future reference.

Periodically inspect and replace hoses if bulges, kinks, cuts, wear, or leaks are found. - Check for leaks

Turn on the water faucets to check for leaks from the faucet and at the washer connection. A small amount of water may enter the washer. You will drain this in a later step.

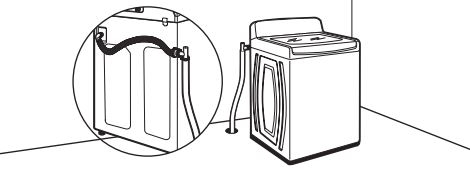

Turn on the water faucets to check for leaks from the faucet and at the washer connection. A small amount of water may enter the washer. You will drain this in a later step. - Secure drain hose

Secure the drain hose to the laundry tub leg, drain standpipe or inlet hoses for the wall standpipe with a cable tie (A). This will help reduce the chance of drain water splashing on the floor.

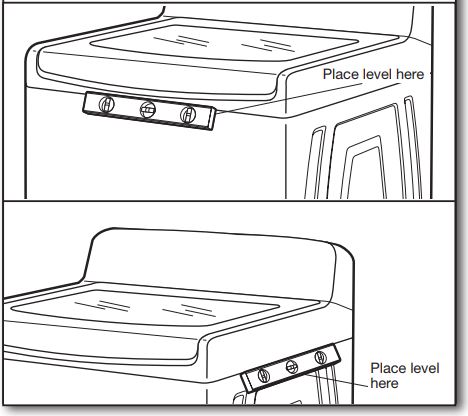

LEVEL WASHER

IMPORTANT: Leveling your washer properly reduces excess noise and vibration.

- Move washer to the final location

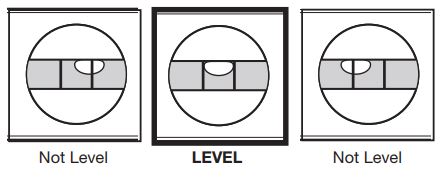

Move the washer to its final location. Rock the washer back and forth to check whether all four feet are stable and in firm contact with the floor. If the washer rocks, minor adjustments may be needed to level the washer on your floor. - Check the levelness of the washer

Check the level of the washer. First, place a level on the lid near the console. Then place the level on the side of the washer in the crease between the top of the washer and the cabinet.

Check the level of the washer. First, place a level on the lid near the console. Then place the level on the side of the washer in the crease between the top of the washer and the cabinet.

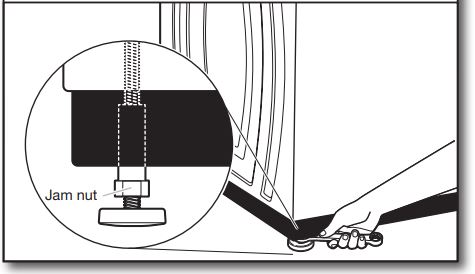

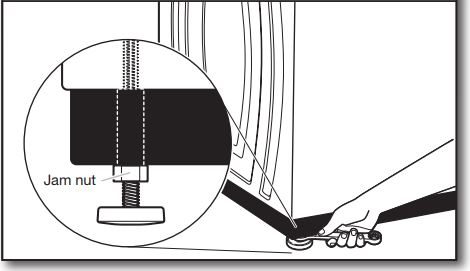

- Adjust leveling feet

If the washer is not level, use a 9/16″ or 14 mm open-end or adjustable wrench to turn jam nuts clockwise on feet until they are about 1/2″ (13 mm) from the washer cabinet. Then turn the leveling foot clockwise to lower the washer or counterclockwise to raise the washer. Recheck the level of the washer and repeat as needed.

If the washer is not level, use a 9/16″ or 14 mm open-end or adjustable wrench to turn jam nuts clockwise on feet until they are about 1/2″ (13 mm) from the washer cabinet. Then turn the leveling foot clockwise to lower the washer or counterclockwise to raise the washer. Recheck the level of the washer and repeat as needed.

HELPFUL TIP: You may want to prop up the front of the washer about 4″ (102 mm) with a wood block or similar object that will support the weight of the washer - Tighten leveling feet

When the washer is level, use a 9/16″ or 14 mm open-end or adjustable wrench to turn jam nuts counterclockwise on leveling feet tightly against the washer cabinet.

HELPFUL TIP: You may want to prop the washer with a wooden block.

- Plug into a grounded 3-prong outlet

COMPLETE INSTALLATION CHECKLIST

- Check electrical requirements. Be sure you have the correct electrical supply and recommended grounding method. See “Electrical Requirements.”

- Check that all parts are now installed. If there is an extra part, go back through the steps to see what was skipped.

- Check that you have all of your tools.

- Keep the foam packing ring from the washer tub for future relocation of the washer. Dispose of/recycle all packaging materials.

- Check that both water faucets are on.

- Check for leaks around faucets and inlet hoses.

- Remove the film from the console and any tape remaining on the washer.

- Check that washer is plugged into a grounded 3-prong outlet.

- Read “Washer Use” in your “Use and Care Guide.”

- To test and clean your washer, measure 1/2 of the normal recommended amount of High Efficiency (HE) powdered or liquid detergent for a medium-sized load and pour it into the detergent dispenser. Close lid. Press POWER. Select a normal cycle and press START. Allow it to complete one whole cycle.

FAQs Maytag MVWB880BW Washer

What is the Maytag Bravos washer’s lifespan?

A Maytag washing machine lasts 11 years on average. If your laundry appliance is a high-end model, Consumer Reports advises waiting to replace it until it is at least eight years old.

Why won’t a Maytag washer turn on?

Examine the outlet: The power wire for the washer should be correctly plugged in. Unplug the washer and plug in a small electronic item to test the outlet’s functionality. Keep extension cords away: The voltage that the washer needs to operate cannot be consistently transmitted by these cords, which causes power interruptions.

What is a Maytag mvwb880bw0’s capacity?

Size: 4.8 cubic feet

How long does a Maytag washer’s typical cycle last?

The average wash cycle lasts between one and two hours, however, actual wash times depend on the model and cycle option. Before you start washing, check your owner’s manual for information on specific cycles, such as how long it takes your washing machine to finish various wash cycles and usage and maintenance guidelines.

Do Maytag washers have a good build?

Many consumers who purchase their laundry appliances believe that Maytag is a dependable brand. Since it is not a luxury brand, you can purchase a durable washer and dryer for a reasonable price. The majority of its items are created in the United States and include customer service protection and extended warranties.

Is there a reset button on Maytag?

Although Maytag washers lack a reset button, it is possible to reset them by pushing a specific set of buttons together. The easiest approach to attempt is this: first press power or cancel. Choose a new cycle to run next.

What’s wrong with the Maytag washer?

Not spinning or agitating, as well as having trouble draining or filling with water, are some of the common Maytag front-load washer issues. It’s possible that your washing machine makes noises or vibrates during the spin and wash cycles. Don’t tolerate misconduct from laundry appliances of this nature.

How long does a typical Maytag wash require?

For a typical wash cycle, front-load washing machine cycle periods might range from 60 to 80 minutes.

What is the lifespan of a Maytag washer?

Maytag washers typically last ten years with proper care and excellent usage practices. A 10-year limited guarantee is also offered with many models, which can help keep the laundry appliance in peak condition.

What is the Maytag washer’s quickest cycle?

Small, lightly soiled loads can be cleaned in 30 minutes using the Quick Wash cycle.

For more Maytag Manuals visit ManualsDock