Koke Inc. Mechanical Manual Dock Leveler

About Koke Inc.

The foremost manufacturer of material handling equipment, including order pickers, warehouse equipment, and forklift accessories, is Koke Incorporated. Koke Inc. produces a wide range of high-quality materials handling equipment that is intended to make your industrial workplace safe and effective. For organizing and moving your products, you need a warehouse, dock, lifting, and safety equipment.

MECHANICAL DOCK LEVELER INSTALLATION INSTRUCTIONS

BEFORE INSTALLATION, CHECK THE PIT FOR CORRECTION DEPTH AND SQUARENESS OF THE PIT ACROSS CORNERS. IF THE PIT IS NOT CORRECT IN SIZE AND QUALITY, MAKE CORRECTIONS BEFORE INSTALLING LEVELER.

IMPORTANT:

DO NOT BREAK BANDS ON LEVELER UNTIL INSTRUCTED

- Place the leveler in the pit using a forklift or crane. Level the back of the leveler with the angle secured in the warehouse floor using appropriate shims.

- Break the steel banding from the leveler, allowing for the operation of the leveler. Release the hold down by pulling up on the chain until the leveler is completely open.

- Brace the deck securely in the up position using the maintenance strut before performing any work inside the leveler.

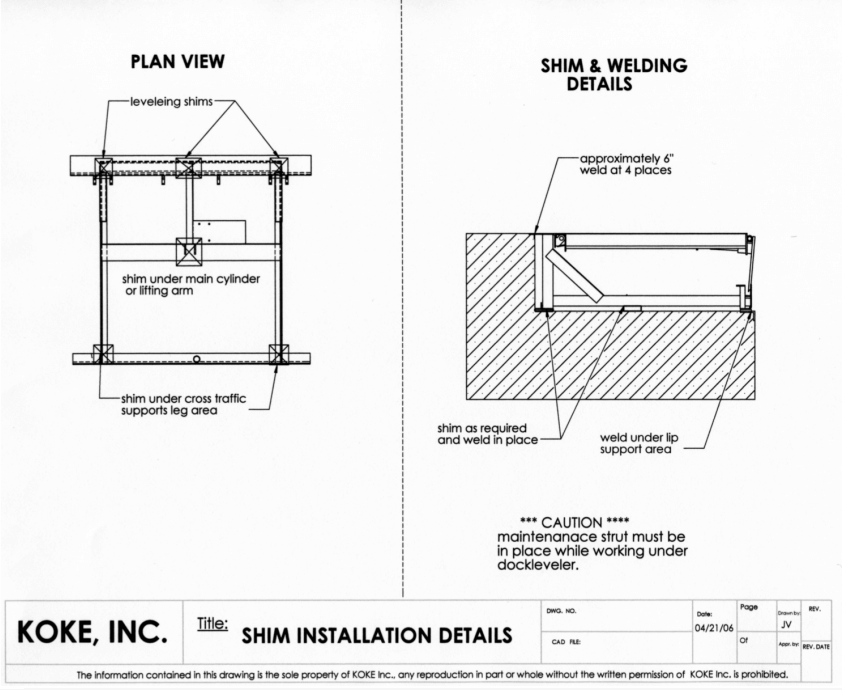

- Shim the rear of the leveler first, then the front of the leveler, so that the leveler is level to floor. Place the appropriate shim under the hold-down location, and weld all shims in place. (shown in Fig. A). (Make sure the leveler is square to the pit walls).

- When the dock leveler is level in the floor front and rear, proceed to stitch weld. (4 welds across the back approximately 6” long, 2 across the front. Note: make sure all shims are welded securely to the base.)

- While the dock leveler is factory tested and adjusted, it may require slight adjustments on-site due to movement in shipping and during installation procedures. This is part of the installation process and it is not a warranty condition.

KOKE INC. RESERVES THE RIGHT TO CHANGE SPECIFICATIONS AND/OR DESIGNS WITHOUT NOTICE OR OBLIGATION.

*PLEASE TATE MODEL # AND SERIAL # OF THE DOCK LEVELER WHEN PLACING AN ORDER FOR PARTS.

PLAN VIEW, SHIM&WELDING DETAILS

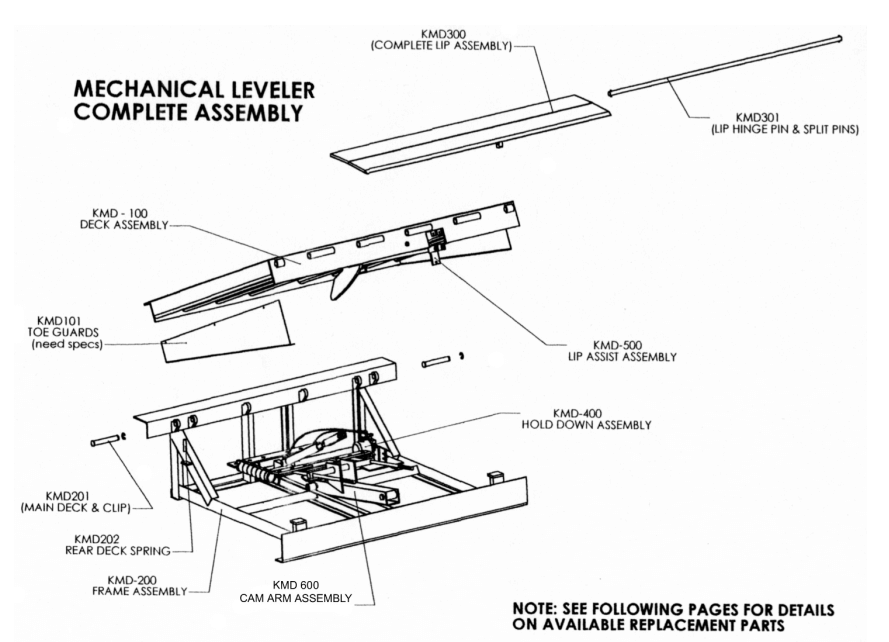

MECHANICAL LEVELER COMPLETE ASSEMBLY

MECHANICAL DOCK LEVELER OPERATION SHEET

CAUTION:

NEVER OPERATE THE DOCK LEVELLER WITH ANYONE STANDING IN FRONT OF THE LIP.

OPERATION INSTRUCTION

- To release the dock leveler from the parked position, known as the “CROSS TRAFFIC POSITION”, pull the release chain and hold until the upward motion stops.

- To lower the dock leveler into a working position, walk to the lip end until the lip rests in/on the truck bed.

- Returning dock leveler to parked position (cross traffic position):

- If the deck is above dock level:

When the lip is in a vertical position, walk the deck platform to the dock-level position. - When loading/unloading has been completed & lip is in the truck/trailer, pull the release chain, allowing the lip to fall to a vertical position then walk leveler to floor level allowing the lip to stop behind the night lock.

- If the deck is above dock level:

NOTE:

After the installation has been completed, the operation process may need to be repeated three to five times to ensure the leveler is working properly.

CAUTION:

THE LIP MUST BE IN ITS VERTICAL POSITION BEFORE A TRUCK IS SPOTTED OR DAMAGE MAY OCCUR TO THE DOCK OF THE TRUCK

MAINTENANCE

WITH PROPER CARE AND MAINTENANCE, YOUR MECHANICAL DOCK LEVELER WILL GIVE MANY YEARS OF SATISFACTORY, TROUBLE-FREE SERVICE.

LUBRICATION:

- LIGHT OIL:

- A. Lip hinge tubes

- B. Lifting arm roller

- C. Lip lifter and latch assembly

- GREASE:

- A. Main lifting spring ends

- B. Rear Hinge pins

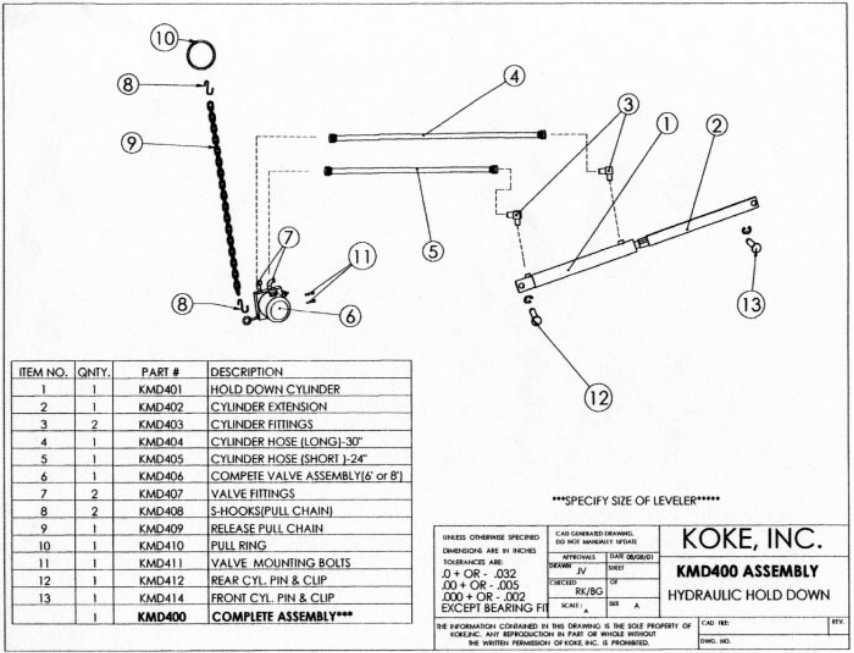

HYDRAULIC HOLD-DOWN:

Keep all parts clean. Change hydraulic fluid once a year. Use a low-temperature hydraulic fluid. DO NOT USE REGULAR HYDRAULIC OIL.

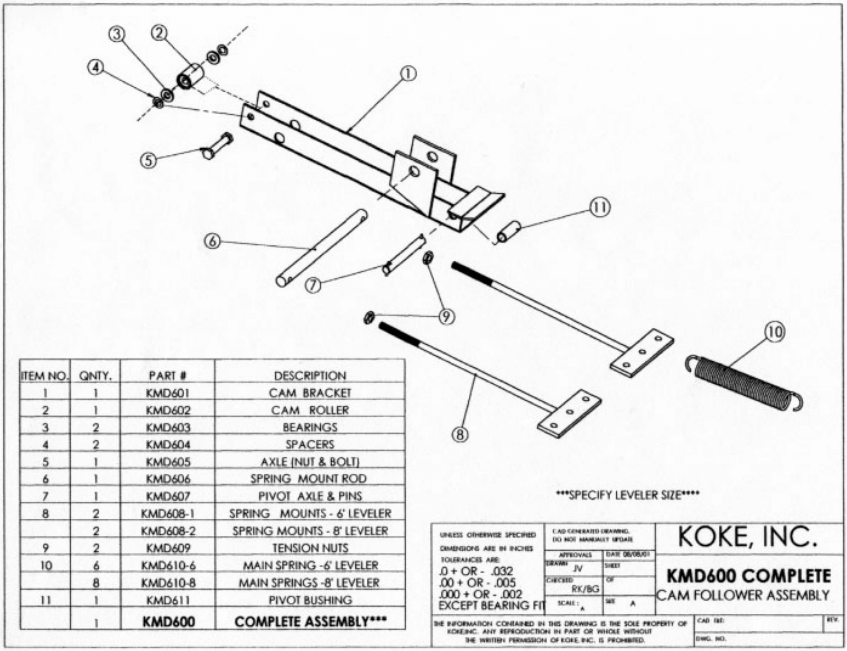

MAIN LIFTING SPRING ADJUSTMENT:

Adjust the main lifting spring: To increase the opening force, tighten the springs evenly. To decrease the walk-down force, loosen the springs evenly.

Note:

Make this adjustment only as necessary and only when all other functions are in proper adjustment.

TROUBLESHOOTING

NOTE:

BEFORE PERFORMING ANY MAINTENANCE CHECKS, ALWAYS POSITION THE WORK STRUT SECURELY UNDER THE DECK & LIP, THEN PROCEED INTO THE PIT TO CLEAN OR MAKE NECESSARY ADJUSTMENTS.

- PROBLEM:

LIP FAILS TO EXTEND CAUSE /ACTION TO BE TAKEN:- Check to see that the leveler is being operated correctly, by pulling on/and holding the release chain until the deck reaches its highest position and lip extends.

- Check for a broken chain or chain connector that activates the lip at the front of the leveler.

- Check for proper lubrication of lip hinge tubes. (keep hinge area clean and free of debris)

- Check for any debris that may cause binding of the lip or any obstructions in the pit that will not allow the leveler to work properly. (clean leveler and pit regularly)

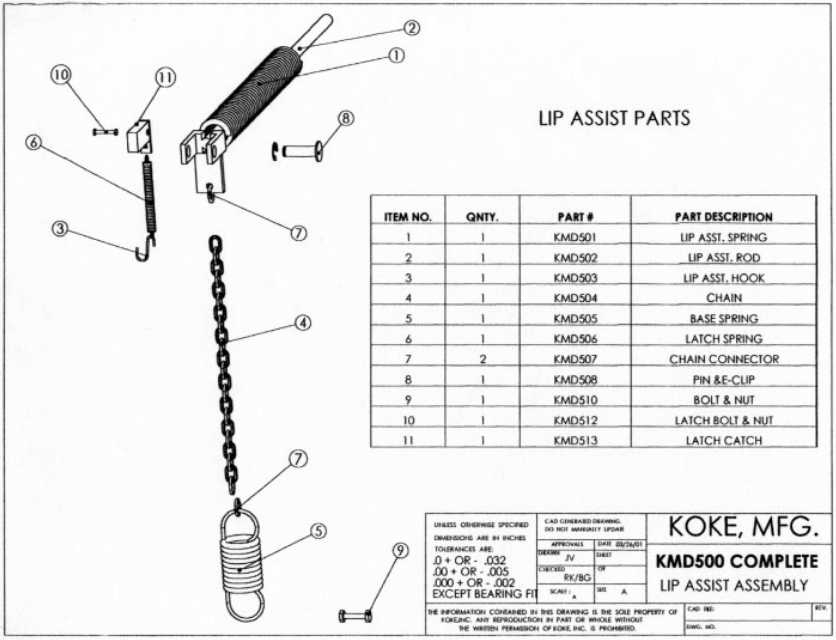

- Check the lip assist spring tension and perform any necessary adjustments.

- ***Too little Tension-lip too heavy

- ***Too much tension lip will not fall into the night lock position

- Check for proper main lifting spring tension and make proper adjustments.

- ***Too Little tension-deck is sluggish & not have enough momentum

- ***Too much tension board will rise too hard

- PROBLEM:

LIP EXTENDS BUT FAILS TO LOCK: CAUSE /ACTION TO BE TAKEN:- Check the lip assist spring tension and adjust accordingly. Adjust the lip assist spring so that the lip is light enough to move from the vertical position. DO NOT OVER-ADJUST TENSION.

- Check to see if the lip extends far enough to engage the latch. If the latch does not engage, adjust the main lifting springs until the lip extends far enough to engage the lip latch.

- Check the main spring tension. If it is too high, this causes the deck to raise too fast, allowing the lip to sing too fast and not allowing the lip to catch and latch. Back off on the adjusting nut at the front of the main spring bank until the lip latches properly.

- Check for any damage to the lip, latch assembly, chain, and spring assembly.

- Check for debris (dirt, sand, any foreign matter) in/on the lip hinge that may hinder the action of the lip. Clean and lubricate hinge tubes until the lip hinges freely.

- PROBLEM:

THE LIP FAILS TO DROP TO ITS PENDANT POSITION WHEN THE TRUCK PULLS AWAY:

CAUSE / POSSIBLE ACTION TO BE TAKEN:- Check the lip latch assembly for any binding or obstruction. Clean and lubricate the latch so that the lip moves freely and the latch is in working condition.

MECHANICAL DOCK LEVELER SERVICE POLICY & WARRANTY

KOKE INC. warrants that each KOKE manufactured product shall be free from defects in materials and workmanship. Any part of this product which under normal and proper use, maintenance proves defective in material and workmanship within (12) twelve months on mechanical components (90) ninety days on electrical components, and (60) sixty months on structural components, provided that notice of any such defects and satisfactory proof of defects is given by the buyer to the seller, with transportation prepaid, and seller’s examination proves such part to be defective.

KOKE’S OBLIGATION UNDER THIS WARRANTY IS LIMITED TO THE REPLACEMENT OF DEFECTIVE COMPONENTS AT THE FACTORY, OR AT THE DISCRETION OF KOKE INC., AT A LOCATION DESIGNATED BY THE COMPANY. KOKE INC. WILL NOT BE LIABLE FOR ANY LOSS, INJURY, OR DAMAGE TO PERSONS OR PROPERTY, NOR FOR DAMAGES OF ANY KIND RESULTING FROM FAILURE OR DEFECTIVE OPERATION OF ANY MATERIALS OR EQUIPMENT.

“NO OTHER WARRANTY EXISTS EXCEPT AS STATED HEREIN”

KOKE INC. is constantly striving to improve its equipment. Improvements and necessary design changes will be made whenever KOKE INC. believes the performance or operation of the equipment will be improved with no obligation to incorporate any improvements to any equipment that may be in service.

CONTACT

KOKE INC.

582 Queensbury Ave.

Queensbury, NY 12804

Phone: (800) 535-5303

Fax: (888) 231-5521

FAQs for Koke Inc. Mechanical Manual Dock Leveler

How is a dock leveler manually released?

Pull the release chain and keep it in place until the upward motion stops to release the dock leveler from the parked position, also known as the “CROSS TRAFFIC POSITION.” 2. Move to the lip end until the lip rests in or on the truck bed to lower the dock leveler into the operational position.

Are mechanical dock levellers powered by electricity?

The advantages of mechanical dock levellers are numerous. An affordable loading dock leveller option is mechanical dock levellers. They require no power to run and are simple to use.

How often does a manual dock leveller need maintenance?

To check for proper operation and any potential risks, the Dock Leveller should be run through at least one complete cycle. Exams must be performed at least once a year.

How durable are manual dock levellers?

Hydraulic dock levellers must also be replaced since the motors deteriorate and the welds crack, especially if they are operated past their 10-year life expectancy and/or beyond their capacity. Keep in mind that over time, this equipment can suffer serious damage, necessitating replacement at some point.

What do you do if the manual dock lip fails to seat properly?

To diagnose and fix it, get in touch with a qualified specialist. Why won’t the dock leveller lip extend far enough to enter the trailer’s back? Typically, this occurs when the dock leveller has to be adjusted or when its springs need to be changed.

Without a loading dock, how can a container be unloaded?

If this applies to you, a portable yard ramp is necessary. A yard ramp is a heavy-duty commercial ramp that may be pushed into position for trailer loading or unloading. For the forklift to be able to access the cargo at the end of the container or trailer, the yard ramp’s top will have a level off.

A manual dock leveller can support how much weight?

Dock levellers typically have capacities ranging from 25,000 to 80,000 pounds. In this capacity range, dock leveller installations make up more than 90% of the total.

Do manual docks require grounding?

To connect all metal components to the alternating current (AC) safety ground at the power source, the metal frame of docks should be bonded. This will make sure the circuit breaker trips if any portion of the metal dock becomes powered up due to an electrical issue. A shock danger can also be caused by nearby docks.

How is the capacity of a manual dock leveller determined?

To determine the safest dock leveller capacity for mild to normal usage, a straightforward formula exists. Total the vehicle’s gross weight and the load’s gross weight. Add these together and multiply the result by 2.5 (8,000 lbs. forklift gross weight plus 4,000 lbs. of gross load equals 12,000 lbs., which is rounded up to 30,000 lbs.).

How is the pressure on a hydraulic valve changed?

Leasing the valve-locking nut on the side will let you to adjust the spool valve. You may access the adjustment screw by removing the locking nut. To increase pressure, turn the screw in a clockwise direction; to decrease pressure, turn it in an anticlockwise direction.

How are hydraulic valves adjusted?

Two fingers are used to rotate the pushrod while gently tightening the lock nut to adjust the hydraulic lifters. When to use this phrase or turn it into a phrase Once the adjuster is properly tightened, the setscrew secures it in place.