KitchenAid KGCD807XSS

About KitchenAid

About KitchenAid

Whirlpool Corporation is the owner of the American home appliance brand KitchenAid. The Hobart Manufacturing Company founded the business in 1919 to make stand mixers; the “H-5” was the first model to be released.

COOKTOP SAFETY

Your safety and the safety of others are very important. We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety messages. This is the safety alert symbol. This symbol alerts you to potential hazards that can kill or hurt you and others. All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.” These words mean:

DANGER You can be killed or seriously injured if you don’t immediately follow instructions

. WARNING: If the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury, or death.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS:

- Do not try to light any appliance.

- Do not touch any electrical switch.

- Do not use any phone in your building.

- Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

- If you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency, or gas supplier.

WARNING: Gas leaks cannot always be detected by smell. Gas suppliers recommend that you use a gas detector approved by UL or CSA. For more information, contact your gas supplier. If a gas leak is detected, follow the “What to do if you smell gas” instructions. In the State of Massachusetts, the following installation instructions apply:

- Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by the State of Massachusetts.

- If using a ball valve, it shall be a T-handle type.

- A flexible gas connector, when used, must not exceed 3 feet.

INSTALLATION REQUIREMENTS

Tools and Parts Gather the required tools and parts before starting installation. Read and follow the instructions provided with any tools listed here.

Tools needed

- Tape measure

- Flat-blade screwdriver

- Phillips head screwdriver

- Drill

- Level

- Marker or pencil

- Pliers

- ¼” drill bit

- Jigsaw

- Ratchet with ³⁄₈” socket

- Pipe-joint compound resistant to LP gas

- Noncorrosive leak-detection solution

Parts supplied

- Vent grill

- Pre-filter

- LP conversion kit

- Burner caps

- Burner grates

- Pressure regulator

Parts needed

- Metal ducting

- Vent clamps

- Wall cap

Check local codes and consult gas suppliers. Check existing gas supply and electrical supply. See “Electrical Requirements” and “Gas Supply Requirements” sections. It is recommended that a licensed, qualified electrical installer make all electrical connections.

Location Requirements IMPORTANT: Observe all governing codes and ordinances. When installing the cooktop, use the minimum dimensions given.

- The installer must comply with installation clearances specified on the model/serial rating plate. The model/serial rating plate is on the downdraft plenum’s side.

- To eliminate the risk of burns or fire by reaching over the heated surface units, cabinet storage space located above the surface units should be avoided. If cabinet storage is to be provided, the risk can be reduced by installing a range hood that projects horizontally a minimum of 5″ (12.7 cm) beyond the bottom of the cabinets.

- The cooktop should be installed in a location away from strong draft areas, such as windows, doors, and strong heating vents or fans.

- All openings in the wall or floor where the cooktop is to be installed must be sealed.

- Cabinet opening dimensions that are shown must be used. Given dimensions are minimum clearances.

- A grounded electrical supply is required. See the “Electrical Requirements” section. A proper gas supply connection must be available. See the “Gas Supply Requirements” section.

- The cooktop is designed to hang from the countertop by its side or rear flanges.

- The gas and electric supply should be located as shown in the “Cabinet Dimensions” section so that they are accessible without requiring the removal of the cooktop.

- Provide a cutout in the right rear corner of the cutout enclosure as shown to provide clearance for the gas inlet, and power supply cord, and to allow the rating label to be visible.

- If the cabinet has drawers, drawers will need to be removed and drawer fronts installed on the front of the cabinet.

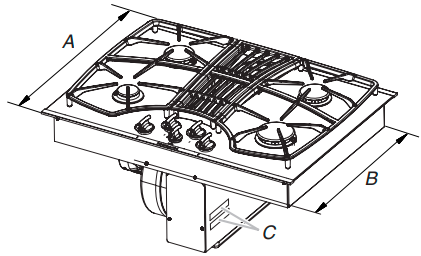

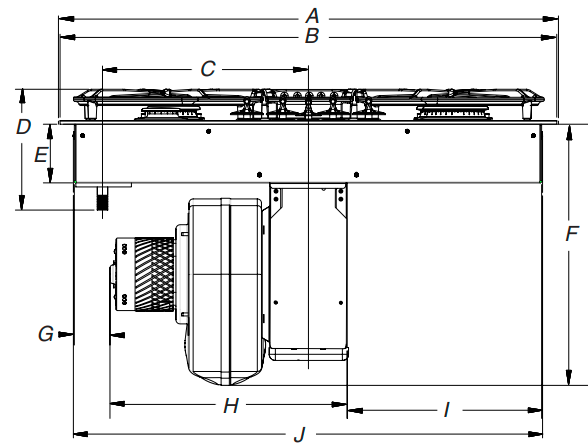

Product Dimensions

30″ (76.2 cm) Cooktop

- 21³⁷⁄₆₄” (54.8 cm) with stainless steel trim or 21½” (54.6 cm) without stainless steel trim

- 19⁴⁷⁄₆₄” (50.1 cm) screw head to screw head

- Model/serial rating/clearance plate location

- 29¹⁵⁄₁₆” (76.1 cm) without stainless steel trim

- 30¹⁄₃₂” (76.3 cm) with stainless steel trim

- 12²⁹⁄₆₄” (31.6 cm) centerline of cooktop to centerline of gas manifold pipe

- 7⁵⁄₁₆” (18.6 cm)

- 3³⁹⁄₆₄” (9.2 cm)

- 15″ (38.1 cm)

- 2⁵⁄₃₂” (5.5 cm) recommended minimum cabinet to motor clearance

- 14¹¹⁄₃₂” (36.4 cm)

- 11⁴⁹⁄₆₄” (29.9 cm)

- 28³⁄₈” (72.1 cm) screw head to screw head

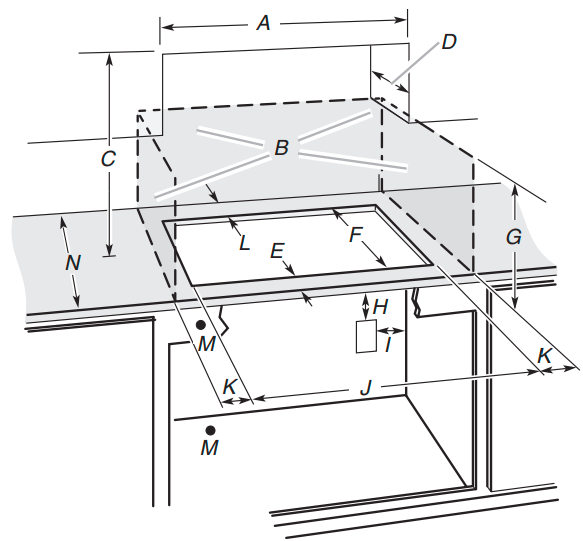

Cabinet Dimensions

- 30″ (76.2 cm)

- Combustible area above countertop (shown by dashed box above)

- 30″ (76.2 cm) minimum clearance between top of cooktop platform and bottom of uncovered wood or metal cabinet (24″ [61.0 cm] minimum clearance if bottom of wood or metal cabinet is covered by not less than ¼” [0.6 cm] flame retardant millboard covered with not less than No. 28 MSG sheet steel, 0.015″ [0.04 cm] stainless steel, or 0.024″ [0.06 cm] aluminum or 0.020″ [0.05 cm] copper)

- 13″ (33.0 cm) recommended upper cabinet depth

- 2¹⁄₈” (5.4 cm)

- 19¹⁵⁄₁₆” (50.6 cm)

- 18″ (45.7 cm) minimum clearance from upper cabinet to countertop within minimum horizontal clearances to cooktop

- Junction box or outlet; 12″ (30.5 cm) minimum from the bottom of the countertop

- Junction box or outlet; 10″ (25.4 cm) from the right-hand side of the cabinet

- 28⁵⁄₈” (72.7cm) on 30″ (76.2 cm) models

- 8″ (20.3 cm) minimum distance to the nearest left and right side combustible surface above the cooktop

- 2″ (5.1 cm) minimum clearance between the back wall and countertop

- Gas line opening – Wall: anywhere 6″ (15.2 cm) below the underside of the countertop on the left side. Cabinet floor: anywhere within 6″ (15.2 cm) of the rear wall on the left side.

NOTES: After making the countertop cutout, some installations may require notching down the base cabinet side walls to clear the cooktop base. To avoid this modification, use a base cabinet with sidewalls wider than the cutout.

- A minimum side clearance of 6″ (15.2 cm) is recommended between the side of the cooktop and the side wall for maximum ventilation performance.

- A minimum clearance of 2″ (5.1 cm) is recommended between the motor/blower and cabinet for proper cooling. A 6″ (15.2 cm) clearance is recommended for servicing access.

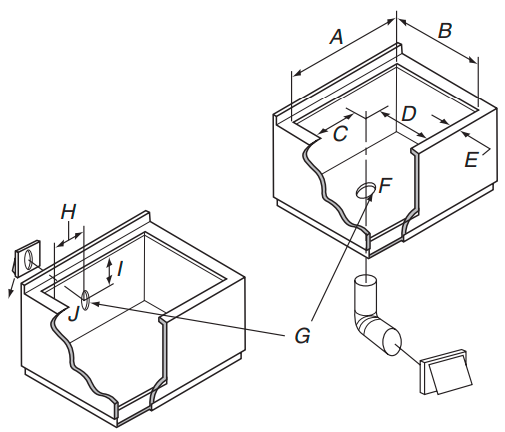

Cutout Dimensions

- 28⁵⁄₈” (72.7 cm) maximum

- 19¹⁵⁄₁₆” (50.6 cm) maximum

- 9⁵⁄₁₆” (21.6 cm)

- 6⁴⁹⁄₆₄” (17.2 cm)

- 2¹⁄₈” (5.4 cm) minimum space to the front edge of the cooktop

- Floor exhaust option

- 6¹⁄₈” (15.6 cm) for a 6″ (15.2 cm) vent system and 5¹⁄₈” (13.1 cm) for a 5″ (12.7 cm) vent system

- 9⁵⁄₁₆” (21.6 cm)

- 13³⁄₈” (33.9 cm) from the top of the countertop surface

- Wall exhaust option

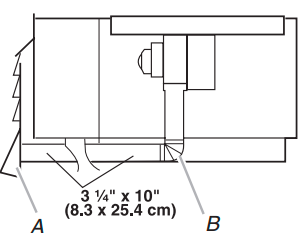

Venting Requirements IMPORTANT: This cooktop must be exhausted outdoors.

- Do not terminate the vent system in an attic or other enclosed area.

- Use a vent cap.

- The vent system must terminate to the outside.

- Use only a 6″ (15.2 cm) diameter round or 3 ¼” x 10″ (8.3 x 25.4 cm) rectangular vent except as follows: For gas models, a 5″ (12.7 cm) diameter round vent must be used if the duct length is 10 ft (3.0 m) or less.

- Before making cutouts, make sure there is proper clearance within the wall or floor for the exhaust vent.

- Do not cut a joist or stud unless necessary. If a joist or stud must be cut, then a supporting frame must be constructed.

- The size of the vent should be uniform.

- The vent system must have a damper. If the roof or wall cap has a damper, do not use the damper supplied with the range hood.

- Use vent clamps to seal all joints in the vent system.

- Use caulking to seal the exterior wall or roof opening around the cap.

- Determine which venting method is best for your application.

For Best Performance:

- Use a 26-gauge minimum galvanized or 25-gauge minimum aluminum metal vent. Poor-quality pipe fittings can reduce airflow. The flexible metal vent is not recommended.

NOTE: Local codes may require a heavier gauge material. - Metal ducts may be reduced to 30-gauge galvanized steel or 26-gauge aluminized steel if allowed by local codes. This reduction is based on information in the International Residential Codes Section M1601.1 (2006 edition).

- Do not install 2 elbows together.

- Use no more than three 90° elbows.

- If an elbow is used, install it as far away as possible from the hood’s vent motor exhaust opening.

- Make sure there is a minimum of 18″ (45.7 cm) of straight vent between the elbows if more than one elbow is used.

- Elbows too close together can cause excess turbulence that reduces airflow.

- Do not use a 5″ (12.7 cm) elbow in a 6″ (15.2 cm) or 3¹⁄₄” x 10″ (8.3 x 25.4 cm) system.

- Do not reduce to a 5″ (12.7 cm) system after using 6″ (15.2 cm) or 3¹⁄₄” x 10″ (8.3 x 25.4 cm) fittings.

- Avoid forming handmade crimps. Handmade crimps may restrict airflow.

- Use the wall caps listed in the “Tools and Parts” section for best performance. If an alternate wall or roof cap is used, be certain the cap size is not reduced and that it has a back draft damper.

- Use vent clamps to seal all joints in the vent system.

- Use caulking to seal the exterior wall or roof opening around the cap.

The length of the vent system and several elbows should be kept to a minimum to provide efficient performance. The maximum equivalent length of the vent system is 60 ft (18.3 m). For altitudes above 4,500 ft (1272 m), reduce the recommended vent run by 20% for best performance.

Cold Weather Installations An additional back draft damper should be installed to minimize backward cold air flow and a thermal break installed to minimize conduction of outside temperatures as part of the vent system. The damper should be on the cold air side of the thermal break.

Makeup Air Local building codes may require using makeup air systems when using ventilation systems greater than the specified CFM of air movement. The specified CFM varies from locale to locale. Consult your HVAC professional for specific requirements in your area.

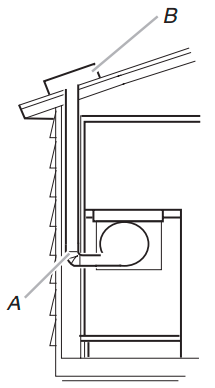

Venting Methods Common venting methods are shown for a counter-mounted downdraft cooktop. The cooktop may be vented through the wall or floor.

Option 1 – Roof Venting

- Roof cap

- 6″ (15.2 cm) round roof venting

Option 2 – Wall Venting

- 6″ (15.2 cm) round wall venting

- Wall cap

Option 3 – Venting Between Floor Joist

- Wall cap

- 6″ (15.2 cm) round wall venting

Option 4 – Venting behind Cabinet Kick Plate

- Wall cap

- 6″ (15.2 cm) round wall venting

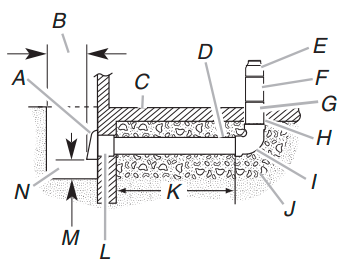

Concrete Slab Installations – Exhaust Through Window Well

- Wall cap

- 12″ (30.5 cm) minimum

- Concrete slab

- 6″ (15.2 cm) round PVC sewer pipe

- 5″ to 6″ (12.7 cm to 15.2 cm) transition

- 6″ (15.2 cm) round metal duct

- 6″ (15.2 cm) round PVC coupling

- 6″ (15.2 cm) round PVC sewer pipe

- 6″ (15.2 cm) round 90° PVC sewer pipe elbow

- Tightly pack gravel or sand completely around the pipe.

- 42 ft (12.8 m) max.

- 6″ (15.2 cm) round PVC coupling

- 6″ (15.2 cm) minimum

- Window well

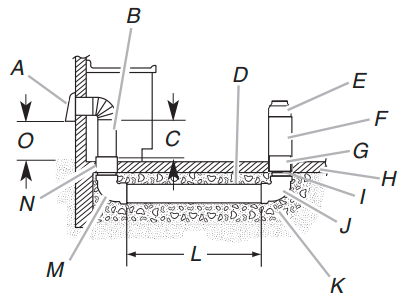

Concrete Slab Installations – Exhaust Through Wall

- Wall cap

- 6″ (15.2 cm) round metal vent

- 16″ (40.6 cm) maximum

- 6″ (15.2 cm) round PVC sewer pipe

- 5″ to 6″ (12.7 cm to 15.2 cm) transition

- 6″ (15.2 cm) round metal duct

- 6″ (15.2 cm) round PVC coupling

- Concrete slab

- 6″ (15.2 cm) round PVC sewer pipe

- 6″ (15.2 cm) round 90° PVC sewer pipe elbow

- Tightly pack gravel or sand completely around the pipe.

- 30 ft (9.1 m) max.

- 6″ (15.2 cm) round 90° PVC sewer pipe elbow

- 6″ (15.2 cm) round PVC coupling

- 12″ (30.5 cm) minimum

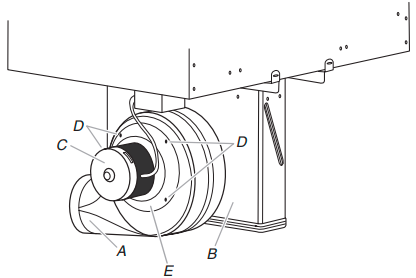

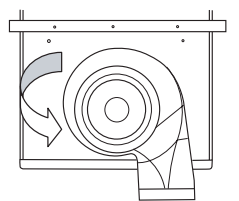

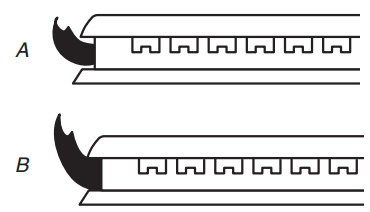

Determine Range Blower Setting

This cooktop is equipped with a dual-range blower. It is shipped from the factory in the low range for most installations. If the equivalent duct length exceeds 30 ft (9.1 m), it must be converted to a high range. Do not convert the blower to a high range for shorter lengths; this will cause excessive noise and conditioned air loss. Convert blower before installing into countertop if necessary.

To Convert to High Range:

- Place the cooktop on the floor with the front edge and plenum down.

- Remove the four #10 – 32 locknuts (A) that attach the blower motor assembly to the blower exhaust scroll.

- Remove the blower motor assembly (B) from the blower exhaust scroll (E).

- Slowly reach into the blower exhaust scroll opening and remove the retainer (C).

- Gently remove the restrictor ring (D).

- Place the motor assembly back on the studs of the blower exhaust scroll.

- Reattach the four #10-32 locknuts to secure the blower motor assembly back to the blower exhaust scroll.

- #10 – 32 Locknut

- Blower motor and wheel assembly

- Retainer

- Restrictor ring

- Exhaust scroll

- Blower wheel guard

Electrical Requirements IMPORTANT:

The cooktop must be electrically grounded by local codes and ordinances, or in the absence of local codes, with the National Electrical Code, ANSI/NFPA 70, or Canadian Electrical Code, CSA C22.1. This cooktop is equipped with an electronic ignition system that will not operate if plugged into an outlet that is not properly polarized. If codes permit and a separate ground wire is used, it is recommended that a qualified electrical installer determine that the ground path is adequate.

- A 120-volt, 60 Hz, AC only, 15-amp, fused electrical circuit is required. A time-delay fuse or circuit breaker is also recommended. It is recommended that a separate circuit serving only this cooktop be provided.

- Electronic ignition systems operate within wide voltage limits, but proper grounding and polarity are necessary. Check that the outlet provides 120-volt power and is correctly grounded.

- The wiring diagrams are provided with this cooktop. See “Wiring Diagrams” on a separate sheet. The wiring diagrams are located on the left underside of the cooktop base.

Gas Supply Requirements WARNING Explosion Hazard

Use a new CSA International-approved gas supply line. Install a shut-off valve. Securely tighten all gas connections. If connected to LP, have a qualified person make sure gas pressure does not exceed 14″ (36 cm) water column. Examples of qualified personnel include licensed heating personnel, authorized gas company personnel, and authorized service personnel. Failure to do so can result in death, explosion, or fire.

IMPORTANT: Leak testing of the cooktop must be conducted according to the manufacturer’s instructions.

Type of Gas Natural Gas: This cooktop is design-certified by CSA International for use with Natural gas or, after proper conversion, for use with LP gas.

- This cooktop is factory set for use with Natural gas. If converting to LP gas, see the “LP Gas Conversion” instructions in the literature package. The model/serial rating plate located on the underside of the cooktop base has information on the types of gas that can be used. If the types of gas listed do not include the type of gas available, check with the local gas supplier.

LP Gas Conversion: Conversion must be done by a qualified service technician. No attempt shall be made to convert the cooktop from the gas specified on the model/serial rating plate for use with a different gas without consulting the serving gas supplier. See the Gas Conversion instructions provided in the package containing literature.

Gas Supply Line

- Provide a gas supply line of ³⁄₄” (1.9 cm) rigid pipe to the cooktop location. A smaller size pipe on longer runs may result in insufficient gas supply. Pipe-joint compounds that resist the action of LP gas must be used. Do not use TEFLON®† tape. With LP gas, piping or tubing size should be ½” minimum. Usually, LP gas suppliers determine the size and materials used in the system.

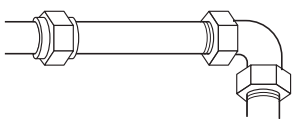

Flexible metal appliance connector:

- If local codes permit, use a ¹⁄₂” or ³⁄₄” I.D. flexible stainless steel tubing gas connector, designed by CSA to connect the cooktop to the rigid gas supply line.

- A ½” male pipe thread is needed for connection to the female pipe threads of the inlet to the cooktop pressure regulator.

- Do not kink or damage the flexible metal tubing when moving the cooktop.

Rigid pipe connection: The rigid pipe connection requires a combination of pipe fittings to obtain an in-line connection to the cooktop. The rigid pipe must be level with the cooktop connection. All strains must be removed from the supply and fuel lines so the cooktop will be level and in line.  Must include a shutoff valve: The supply line must be equipped with a manual shutoff valve. This valve should be in the same room but external to the cooktop opening, such as an adjacent cabinet. It must be accessible without removing the cooktop, and it should be in a location that allows ease of opening and closing. Do not block access to the shutoff valve. The valve is for turning on or shutting off the gas to the cooktop.

Must include a shutoff valve: The supply line must be equipped with a manual shutoff valve. This valve should be in the same room but external to the cooktop opening, such as an adjacent cabinet. It must be accessible without removing the cooktop, and it should be in a location that allows ease of opening and closing. Do not block access to the shutoff valve. The valve is for turning on or shutting off the gas to the cooktop.

- Gas supply line

- Shutoff valve “open” position

- To cooktop

Gas Pressure Regulator The gas pressure regulator supplied with this cooktop must be used. The inlet pressure to the regulator should be as follows for proper operation:

Natural Gas: Minimum pressure: 5″ (12.7 cm) WCP Maximum pressure: 7″ to 14″ (17.8 cm to 35.5 cm) WCP

LP Gas: Minimum pressure: 10″ (25.4 cm) WCP Maximum pressure: 14″ (35.5 cm) WCP Contact the local gas supplier if you are not sure about the inlet pressure.

Burner Input Requirements Input ratings shown on the model/serial rating plate are for elevations up to 2,000 ft (609.6 m). For elevations above 2,000 ft (609.6 m), ratings should be reduced at a rate of 4% for each 1,000 ft (304.8 m) above sea level (not applicable for Canada).

Gas Supply Pressure Testing The gas supply pressure for the testing regulator must be at least 1″ water column pressure above the manifold pressure shown on the model/serial rating plate.

Line pressure testing above ½ psi gauge (14″ WCP) The cooktop and its shutoff valve must be disconnected from the gas supply piping system during any pressure testing of that system at test pressures over ½ psi (3.5 kPa).

Line pressure testing at ½ psi gauge (14″ WCP) or lower The cooktop must be isolated from the gas supply piping system by closing its manual shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or less than ½ psi (3.5 kPa).

INSTALLATION INSTRUCTIONS

Install Cooktop Decide on the final location for the cooktop.

WARNING Excessive Weight Hazard Use two or more people to move and install the cooktop. Failure to do so can result in back or other injury.

- Open the carton as instructed on the product packaging.

- Remove shipping materials and tape from the cooktop.

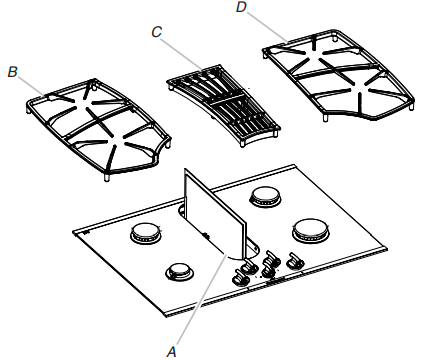

- Remove the removable grease filter by lifting the filter out.

- For island or peninsula installations, go to the “Rotate Blower – Optional” section. Removable grease filter

- Left side grate

- Vent grille

- Right side grate

- Using 2 or more people, remove the cooktop from the carton.

REMEMBER: An under-counter built-in oven cannot be installed under this cooktop. - Place the cooktop right side up into the cutout.

NOTE: Make sure that the front edge of the cooktop is parallel to the front edge of the countertop. If repositioning is needed, lift the entire cooktop from the cutout to avoid scratching the countertop. - Connect blower exhaust scroll to ducting.

- Use vent clamps to secure the ducting to the blower exhaust scroll.

- Reinstall the grease filter.

- Reinstall vent grille.

Rotate Blower – Optional IMPORTANT: The following additional steps must be performed if the product is being installed in peninsula or island cabinetry. The blower exhaust scroll is shipped from the factory set to exhaust straight out the back of the cabinet through an exterior wall.

- Blower exhaust scroll

- Plenum

- Blower motor

- #10-32 locknuts (4)

- Motor mounting plate

To rotate the blower:

- Remove the right and left grates. Then remove the vent grille. See the illustration in Step 4 of the “Install Cooktop” section.

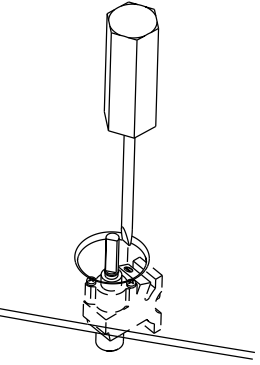

- Locate the 4 locknuts inside the plenum.

#10 – 32 locknut

#10 – 32 locknut

- Plenum

- Flat washer

- Blower guard

- Use ³⁄₈” socket and ratchet handle to loosen the nut half of a rotation. Repeat this process for each of the 4 nuts.

- With the nuts loosened, the blower exhaust scroll can be easily rotated downward.

- Retighten each nut with the ³⁄₈” socket, extension, and ratchet.

Make Gas Connection WARNING Explosion Hazard Use a new CSA International-approved gas supply line. Install a shut-off valve. Securely tighten all gas connections. If connected to LP, have a qualified person make sure gas pressure does not exceed 14″ (36 cm) water column. Examples of qualified personnel include licensed heating personnel, authorized gas company personnel, and authorized service personnel. Failure to do so can result in death, explosion, or fire.

- Apply pipe-joint compound made for use with Natural and LP gas to the smaller thread ends of the flexible connector adapters (see C and G in the following illustration).

- Attach one adapter to the gas pressure regulator and the other adapter to the gas shutoff valve. Tighten both adapters.

- Use a ¹⁵⁄₁₆” combination wrench and channel lock pliers to attach the flexible connector to the adapters. Check that the connector is not kinked.

Typical flexible connection.- Manifold entrance

- Gas pressure regulator

- Use pipe-joint compound.

- Adapter (must have ½” male pipe thread)

- Flexible connector

- Adapter

- Use pipe-joint compound.

- Manual gas shutoff valve

- ½” or ¾” gas pipe

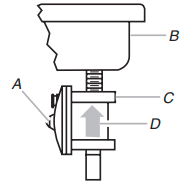

- Install the pressure regulator with the arrow pointing up toward the bottom of the cooktop base and in a position where you can reach the regulator access cap.

- Access cap

- Rear of cooktop

- Gas pressure regulator

- Up arrow. The regulator must be installed with an arrow pointing up to the cooktop bottom.

IMPORTANT: All connections must be wrench-tightened. Do not make connections to the gas regulator too tight. Making the connections too tight may crack the regulator and cause a gas leak. Do not allow the regulator to turn on the pipe when tightening fittings. Use only pipe-joint compounds made for use with Natural and LP gas. Do not use TEFLON® tape. You will need to determine the fittings required depending on your installation.

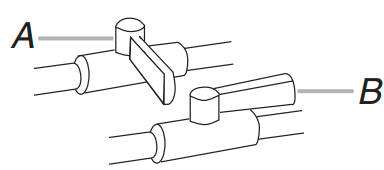

Complete Connection

- Open the manual shutoff valve in the gas supply line. The valve is open when the handle is parallel to the gas pipe.

- Closed valve

- Open valve

- Test all connections by brushing on an approved noncorrosive leak-detection solution. If bubbles appear, a leak is indicated. Correct any leak found.

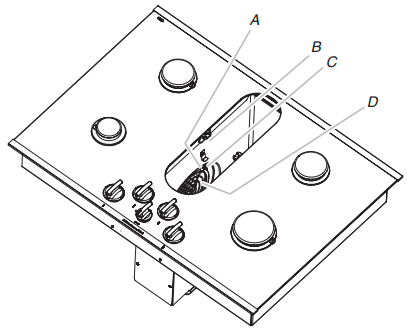

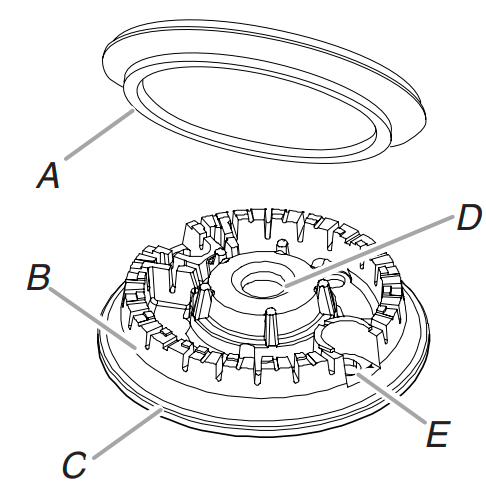

- Remove surface burner caps and grates from the parts package. Align notches in burner caps with pins in burner base. Burner caps should be level when properly positioned. If burner caps are not properly positioned, surface burners will not light. Place burner grates over burners and caps.

- Burner cap

- Burner ports

- Burner base

- Gas tube opening

- Igniter head

- Plug into a grounded 3-prong outlet.

Electronic Ignition System Initial lighting and gas flame adjustments This cooktop is equipped for electronic auto-reignition using a spark igniter located at the rear of each burner. The burners are designed to light at any valve rotation that admits sufficient gas flow to support a flame and to automatically relight following a loss of flame due to a draft or other adverse condition. This feature is provided only as a convenience.

Check the Operation of Surface Burners Push in and turn the surface burner’s control knobs to light. The surface burner flame should light within 4 seconds. The first time a surface burner is lit, it may take longer than 4 seconds to light because of air in the gas line. Check the flame on “HIGH” for a blue color. It should be clean and soft. No yellow tip, blowing, or lifting of flame should occur. Occasional orange flashes are normal and reflect different elements in the air or gas. After verifying the proper burner operation, turn the control knobs to “OFF.”

If burners do not light properly:

- Turn the surface burner control knob to the “OFF” position.

- Check that the power supply cord is plugged in and the circuit breaker has not tripped or the fuse blown.

- Check that the gas shutoff valves are set to the “open” position.

- Check that burner caps are properly positioned on burner bases.

Recheck operation of surface burners. If a burner does not light at this point, contact your dealer or authorized service company for assistance.

Adjust Flame Height Smart Port Burner System This cooktop is equipped with a Smart Port Burner System. The Smart Port Burner System produces a small flame directly under each grate finger and a larger flame between each grate finger. The visual difference between the ports will be noticeable when the burner is used or when adjustments are made to the flame length. Adjust the height of the top burner flames. The cooktop “low” burner flame should be a steady blue flame approximately ¼” (0.64 cm) high.

- Low flame

- High flame

To adjust standard burners: The flame can be adjusted using the adjustment screw in the center of the valve stem. The valve stem is located directly underneath the control knob.

If the “low” flame needs to be adjusted:

- Light 1 burner and turn to the lowest setting.

- Remove the control knob.

- Hold the knob stem in the low position using a pair of pliers. Use an ¹⁄₈” (3.0 mm) flat-blade screwdriver to turn the screw located in the center of the control knob stem until the flame is the proper size.

- Replace the control knob.

- Test the flame by turning the control from “LO” to “HI,” checking the flame at each setting.

- Repeat the above steps for each burner.

Complete Installation

- Check that all parts are now installed. If there is an extra part, go back through the steps to see which step was skipped.

- Check that you have all your tools.

- Dispose of/recycle all packaging materials.

- Use a mild solution of liquid household cleaner and warm water to clean the cooktop before use. Dry thoroughly with a soft cloth. For more information, see the “Cooktop Care” section of the Use and Care Guide.

- Read “Cooktop Use” in the Cooktop Use and Care Guide.

- Reconnect power.

NOTE: If the cooktop does not work after turning on the power, check that a circuit breaker has not tripped or a household fuse has not blown. See the “Troubleshooting” section in the Use and Care Guide for further information. - Use the Flow Tester Card provided with your cooktop to check the airflow (see card for step-by-step instructions).

If you need Assistance or Service: Please reference the “Assistance or Service” section of the Use and Care Guide or contact the dealer from whom you purchased your cooktop.

A copy of the above code standards can be obtained from: National Fire Protection Association One Batterymarch Park Quincy, MA 02269 CSA International 8501 East Pleasant Valley Road Cleveland, Ohio 44131-5575

FAQs About KitchenAid KGCD807XSS

Is a downdraft necessary for my electric cooktop?

Homeowners should still install ventilation to their kitchen to aid with cooking fumes, smoke, and other vapors produced during food preparation, even if electric cooktops don’t produce fumes like those that come from a natural gas or propane burning range.

Does a downdraft occur due to heat?

The air must become colder than the surrounding air for downdrafts to form. This takes place when precipitation forms and evaporates. Usually, precipitation forms when temperatures are low enough and altitudes are high enough for it to solidify.

Does a downdraft have to exist?

Not all homes are a good fit for downdraft vents. They are not ideal for large-scale cooking projects because to their limits and difficulty meeting airflow requirements. What they excel at offering the typical home cook quiet, efficient performance and strong, slim-profile ventilation for both big and small space designs.

Can a range have a downdraft added to it?

You can include a downdraft range hood into your current setup if you currently have a regular range or cooktop and wish to use a downdraft system. Simply install a retractable downdraft range hood, such as the Maytag brand’s, behind your gas or electric range.

Is a downdraft required for a gas stove?

Because gas stoves release dangerous PM 2.5 particles, it is imperative that they are vented correctly for your health and safety. These minute particles have the ability to enter the lungs and respiratory system deeply. They are particularly dangerous for those who already have asthma or other related pre-existing diseases.

How can a downdraft be eliminated?

By changing the damper, downdrafts can frequently be avoided and corrected. A fireplace’s damper needs to be at least half open all the time in order for it to work correctly. If it’s completely closed, hot air and smoke won’t escape through the chimney and flue but will instead build up within your house.

What does a weather downdraft mean?

Downdraft, or DWNDFT for short, is – a little air column that quickly descends to the earth; typically, it is accompanied by precipitation, like in a shower or thunderstorm. A powerful downdraft leads to a downburst.

How can a downdraft be avoided?

Downdrafts can be avoided by warming the flue before lighting a chilly fireplace. By lighting a piece of cardboard or rolled-up newspaper inside the firebox beneath the flue opening and holding it there until the draft reverses and the heat rises up the chimney, you can warm the flue.

Should I vent my gas cooktop?

Most residential residences in the United States that use gas for cooking do not require venting their range. That does not mean, however, that you shouldn’t merely because you are not required to. You will have to utilize a commercial-style range if you use one.

Are downdrafts effective?

Although they’re not the best ventilation option for every kitchen, downdraft vents can work well in some circumstances. There are several reasons why people choose downdraft ventilation ranges: No ducting is required: All you have to do is install the range.

For more manuals by KitchenAid ManualsDock