Campbell Hausfeld Air Compressor

ABOUT Campbell Hausfeld

Based in Harrison, Ohio, Campbell Hausfeld is a maker of low-cost, high-quality air compressors for residential, commercial, and industrial use. It is a sizable subsidiary of Berkshire Hathaway’s Marmon Group, which is itself a subsidiary. One of Ohio’s oldest businesses is this one.

Important Safety Information

Please read and save these instructions. Read carefully before attempting to assemble, install, operate, or maintain the product described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference. This manual contains important safety, operational, and maintenance information. If you have any questions, please visit www.campbellhausfeld.com for customer assistance.

General Safety

Since the air compressor and other components (material pump, spray guns, filters, lubricators, hoses, etc.) used to make up a high-pressure pumping system,

The following safety precautions must be observed at all times:

- Read all manuals included with this product carefully. Be thoroughly familiar with the controls and the proper use of the equipment.

- Follow all local electrical and safety codes as well as the United States National Electrical Codes (NEC) and Occupational Safety and Health Act (OSHA).

- Only persons well acquainted with these rules of safe operation should be allowed to use the compressor.

- Keep visitors away and NEVER allow children in the work area.

- Wear safety glasses and use hearing protection when operating the unit.

- Do not stand on or use the unit as a handhold.

- Before each use, inspect the compressed air system and electrical components for signs of damage, deterioration, weakness or leakage. Repair or replace defective items before using.

- Check all fasteners at frequent intervals for proper tightness.

SPECIFICATIONS

| CE5003 | XC802100 | |

| HP (Horsepower) | 5 | 5 |

| Number of Cylinders | 4 | 4 |

| Number of Stages | 2 | 2 |

| Air Delivery @ 90 PSI | 15.8 CFM | 15.8 CFM |

| Voltage | 230 Volts /

22 Amps |

230 Volts /

22 Amps |

| Max Pressure | 175 PSI | 175 PSI |

| Oil Capacity | 47.4 ounces | 47.4 ounces |

| Tank Outlet Size | 3/4 NPT | 3/4 NPT |

| Weight | 410 lbs. | 410 lbs. |

DIMENSIONS

| CE5003 | XC802100 | |

| Length | 26.4 inches | 26.4 inches |

| Width | 27.97 inches | 27.97 inches |

| Height | 69.6 inches | 69.6 inches |

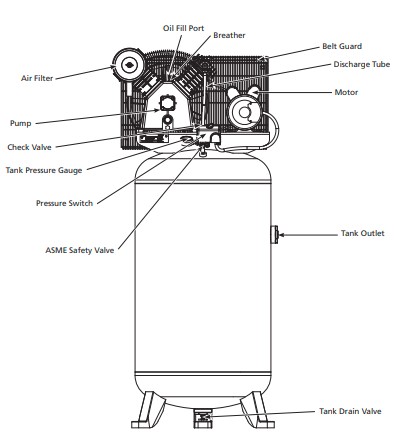

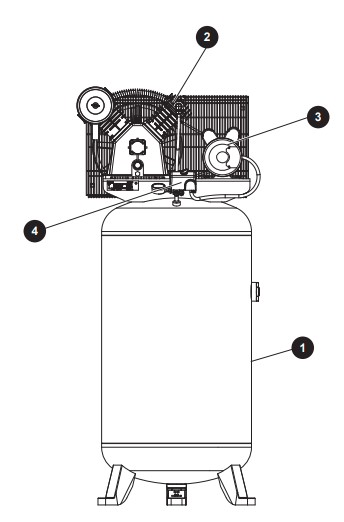

GETTING TO KNOW YOUR UNIT

- Pressure Switch – Auto/Off Switch – In the auto position, the compressor shuts off automatically when tank pressure reaches the maximum preset pressure. After air is used from the tank and drops to a preset low level, the pressure switch automatically turns the motor back on. In the off position, the compressor will not operate. This switch should be in the off position when connecting or disconnecting the power from the unit. When the pressure switch turns the motor off you will hear air leaking out of the pressure switch unloader valve for a short time. This releases the air pressure from the discharge tube and allows the compressor to restart easier.

- ASME Safety Valve – This valve automatically releases air if the tank pressure exceeds the preset maximum.

- Discharge Tube – This tube carries compressed air from the pump to the check valve. This tube becomes very hot during use. To avoid the risk of severe burns, never touch the discharge tube.

- Check Valve – One-way valve that allows air to enter the tank, but prevents air in the tank from flowing back into the compressor pump.

- Belt Guard – Covers the belt, motor pulley and flywheel.

- Tank Drain Valve – This valve is located on the bottom of the tank. Use this valve to drain moisture from the tank daily to reduce the risk of corrosion.

- Tank Pressure Gauge – Indicates amount of air pressure stored in tank.

- Air Filter – Keeps large particulates out of the air flowing into the compressor.

- Breather – Vent for crankcase.

- Oil Fill Port – Port used to refill the oil in the pump after oil changes or when oil is low.

- Pump – Cast Iron 2-Stage air compressor pump that generates compressed air.

- Motor – Power source that drives the pump to create compressed air.

- Tank Outlet – This is where you plumb into to get compressed air from the pressure vessel. An isolation valve should be installed here to be able to shut off the air supply from the tank.

INSTALLATION INSTRUCTIONS

Preparation

Before beginning installation and/or assembly of the product, make sure all parts are present. Compare parts with the package contents list. If any part is missing or damaged, do not attempt to assemble or use the product.

Estimated Installation and Assembly Time: 120 minutes

Tools Required for Installation and Assembly (not included): Safety Glasses; Work Gloves; 9/16 in. Socket and Ratchet; Tape measure; Hammer Drill and Masonry Bit; Hammer; Phillips Screwdriver; Flathead Screwdriver; Pipe Wrench; Two Adjustable Wrenches; 1/4 in. Nut Driver, Socket or Wrench; 240 Volt, 30 Amp Double Pole Circuit Breaker; Voltage Meter; Vibration Pads; 3/8 in. x 5 in. Wedge Anchors (for concrete installation).

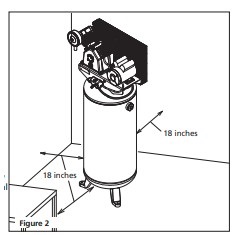

Picking the Location Install and operate the unit at least 18 inches from any obstructions in a clean, well-ventilated area. The surrounding air temperature should not exceed 100° F. This will ensure an unobstructed flow of air to cool the compressor and allow adequate space for maintenance.

CAUTION Do not locate the compressor air inlet near the steam, paint spray, sandblast areas, or any other source of contamination.

NOTE: If the compressor operates in a hot, moist environment, supply the compressor pump with clean, dry outside air. Supply air should be piped in from external sources.

Tank Mounting

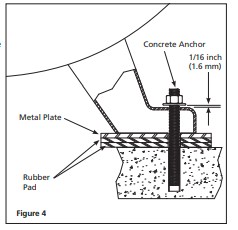

The tank should be bolted into a flat, even, concrete floor or on a separate concrete foundation. Vibration isolators should be used between the tank leg and the floor. Model MP345700AJ isolator pads are recommended for installation.

WARNING Failure to properly install the tank can lead to cracks at the welded joints and possible bursting.

- Unbolt the unit from the shipping skid. Use a ratchet with a 9/16 in. socket. Remove the unit from the skid. This requires at least two people one person to walk the unit off the skid and one to help maintain balance so the unit does not topple. Place the unit where you plan to install it (at least 18 in. from any wall or surface).

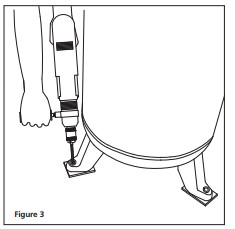

- Place pre-drilled vibration pads (sold separately) under each foot to avoid unnecessary vibration which could damage the unit. Using the mounting holes and the holes of the vibration pads as a guide, drill holes into the concrete using a 3/8 in. masonry bit. Holes drilled must be at least 5 in. into the concrete.

- Insert mounting bolts. Use 3/8 in. x 5 in. wedge anchors (not included) to secure the unit. Place the nut and washer on the bolt. Thread nut onto bolt until tops are flush. Strike the bolt with a hammer until the nut and washer are set on top of the compressor foot. Tighten the nut using a ratchet with a 9/16 in. socket until the anchor is set (using installation torque specifications of the bolt being used). Loosen the nut to leave a 1/16 in. (1.6 mm) gap for stress relief during unit operation.

Piping Any tube, pipe, or hose connected to the unit must be able to withstand the temperature generated and retain the pressure. All pressurized components of the air system must have a pressure rating of 200 PSI or higher. The minimum recommended pipe size is 3/4 in. A larger diameter pipe is always better. Incorrect selection and installation of any tube, pipe or hose could result in bursting and injury. Connect the piping system to the tank using the same size fitting as the discharge port.

Minimum Pipe Size For Compressed Air Line

|

CFM |

LENGTH OF PIPING SYSTEM | |||

| 25 FEET | 50 FEET | 100 FEET | 250 FEET | |

| 10 | 1/2 inch | 1/2 inch | 3/4 inch | 3/4 inch |

| 20 | 3/4 inch | 3/4 inch | 3/4 inch | 1 inch |

| 40 | 3/4 inch | 1 inch | 1 inch | 1 inch |

| 60 | 3/4 inch | 1 inch | 1 inch | 1 inch |

| 100 | 1 inch | 1 inch | 1 inch | 1-1/4 inch |

TROUBLESHOOTING GUIDE

| SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION | |||||

| Low discharge pressure | 1. | Air demand exceeds pump capacity | 1. Reduce air capacity. | demand or use a compressor with more | |

| 2. | Air leaks (fittings, tubing on compressor, or plumbing outside of system). | 2. Listen for all fittings at points fittings or | escaping air. Apply soap solution to and connections. Bubbles will appear

of leakage. Tighten or replace leaking connections. Use pipe thread sealant. |

||

| 3. | Restricted air intake | 3. Clean or replace | the air filter element. | ||

| 4. | Blown gaskets | 4. Replace any gaske | ts proven faulty on inspection. | ||

| 5. | Leaking or damaged valves | 5. Remove head and inspect for valve breakage, misaligned valves, damaged valve seats, etc. Replace defective parts and reassemble. | |||

|

|

Install a new head gasket

each time the head is removed. |

||||

| Excessive noise (knocking) | 1. | Loose motor pulley or flywheel. | 1. Tighten pulley / screws. | flywheel clamp bolts and set- | |

| 2. | Loose fasteners on pump or motor. | 2. Tighten fasteners. | |||

| 3. | Lack of oil in crankcase | 3. Check for proper oil level; if low, check for possible damage to bearings. Dirty oil can cause excessive wear. | |||

| 4. | Worn connecting rod | 4. Replace connecting rod. Maintain oil level and change oil more frequently. | |||

| 5. | Worn piston pin bores | 5. Remove piston assemblies from the compressor and | |||

| inspect for excess wear. Replace excessively worn piston pin or pistons, as required. Maintain oil level and change oil more frequently.

6. Piston hitting the valve plate 6. Remove the compressor head and valve plate and inspect for carbon deposits or other foreign matter on top of piston. Replace head and valve plate using new gasket. See Lubrication section for recommended oil. 7. Noisy check valve in compressor 7. Replace check valve. system Do not disassemble check valve with air pressure in tank. |

|||||

| Large quantity of oil in the discharge air | 1. | Worn piston rings | 1. Replace with new rings. Maintain oil level and change oil more frequently. | ||

MAINTENANCE AND INSPECTION INSTRUCTIONS

All repairs should be performed by an authorized service representative. In order to maintain efficient operation of the compressor system, check the air filter and oil level before each use. The ASME safety valve should also be checked daily (see Figure 18). Pull ring on the safety valve and allow the ring to snap back to its normal position. This valve automatically releases air if the tank pressure exceeds the preset maximum. If air leaks after the ring has been released, or the valve is stuck and cannot be actuated by the ring, the ASME safety valve must be replaced.

REPAIR PARTS ILLUSTRATION FOR CE5003 AND XC802100

For Repair Parts, visit www.campbellhausfeld.com 24 hours a day – 365 days a year

Please provide the following information:

- Model number

- Serial number (if any)

- Part description and number as shown in the parts list

| Ref. No. |

Description |

Part Number: |

Qty. |

| 1 | 80 Gallon Tank | AR901500CG | 1 |

| 2 | 5HP 2-Stage Reciprocating Pump | XC002500IP | 1 |

| 3 | 5HP Electric Motor | MC035700IP | 1 |

| 4 | Pressure Switch | CW220000AV | 1 |

UNIT SERVICE PARTS

|

Description |

Part Number: |

Qty. |

| Drain Valve | SR060513SV | 1 |

| Motor Pulley | PU019400AV | 1 |

| Vee Belt | BT013101AV | 1 |

| Check Valve/Exhaust Tube Kit | XC001900SV | 1 |

| Pressure Switch Kit | MY001100SV | 1 |

| Belt Guard Kit | BG900100SV | 1 |

PUMP SERVICE PARTS

|

Description |

Part Number: |

Qty. |

| Valve Replacement Kit | XC001000AV | 1 |

| Ring Replacement Kit | XC001100AV | 1 |

| Gasket Kit | XC001300AV | 1 |

| Flywheel | XC001400AV | 1 |

| Pump Accessories | XC001500AV | 1 |

| Air Filter Element | XC001700AV | 1 |

LIMITED WARRANTY

- DURATION: From the date of purchase by the original purchaser as follows: Three Years.

- WHO GIVES THIS WARRANTY: Campbell Hausfeld a Marmon/Berkshire Hathaway Company, 350 Embry Drive, Leitchfield, KY, 42754. Visit www.campbellhausfeld.com.

- WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the

compressor. - WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: This air compressor.

- WHAT IS COVERED UNDER THIS WARRANTY: Parts and Labor to remedy substantial defects due to material and

workmanship during the first year of ownership with the exceptions noted below. Parts only to remedy substantial defects

due to material and workmanship during remaining term of coverage with exceptions noted below. - WHAT IS NOT COVERED UNDER THIS WARRANTY:

- Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED FROM THE DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION.

- Some States do not allow limitations on how long an implied warranty lasts, so the above limitations may not apply to you

- ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY DEFECT, FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT. Some States do not allow the exclusion or limitations of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

- Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in accordance with instructions provided in the owner’s manual(s) supplied with compressor.

- Pre-delivery service, e.g. assembly, oil or lubricants, and adjustment.

- Items or service that is normally required to maintain the product, i.e. lubricants, filters and gaskets, etc.

- Additional items not covered under this warranty:

- Excluded items pertaining to All Compressors

- Any component damaged in shipment or any failure caused by installing or operating unit under conditions not

in accordance with installation and operation guidelines or damaged by contact with tools or surroundings. - Pump or valve failure caused by rain, excessive humidity, corrosive environments or other contaminants.

- Cosmetic defects that do not interfere with compressor functionality.

- Rusted tanks, including but not limited to rust due to improper drainage or corrosive environments.

- The following components are considered normal wear items and are not covered after the first year of ownership. Electric motor, check valve, pressure switch, regulator, pressure gauges, hose, tubing, pipe, fittings and couplers, screws, nuts, hardware items, belts, pulleys, flywheel, air filter and housing, gaskets, seals, oil leaks, air leaks, oil consumption or usage, piston rings.

- Tank drain valves.

- Damage due to incorrect voltage or improper wiring.

- Other items not listed but considered general wear parts.

- Pressure switches, air governors, load/unload devices, throttle control devices and safety valves modified from factory settings.

- Damage from inadequate filter maintenance.

- Induction motors operated with electricity produced by a generator.

- Excluded items specific to Lubricated Compressors:

- Pump wear or valve damage caused by using oil not specified.

- Pump wear or damage caused by any oil contamination.

- Pump wear or damage caused by failure to follow proper oil maintenance guidelines, operation below proper oil level or operation without oil.

- Labor, service call, or transportation charges after the first year of ownership of stationary compressors. Stationary compressors are defined as not including a handle or wheels.

- RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, compressor or component which is defective, has malfunctioned and/or failed to conform within the duration of the specific warranty period.

- RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

- Provide dated proof of purchase and maintenance records.

- Visit www.campbellhausfeld.com to obtain your warranty service options. Freight costs must be borne by the purchaser.

- Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

- Repairs requiring overtime, weekend rates, or anything beyond the standard manufacturer warranty repair labor

reimbursement rate. - Time required for any security checks, safety training, or similar for service personnel to gain access to facility.

- Location of unit must have adequate clearance for service personnel to perform repairs and be easily accessible.

- WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or replacement will be scheduled and serviced according to the normal work flow at the servicing location, and depending on the availability of

replacement parts. This Limited Warranty applies in the U.S., Canada and Mexico only and gives you specific legal rights. You may also have other rights which vary from state to state or country to country

FAQs Campbell Hausfeld Air Compressor

What is a Campbell Hausfeld Air Compressor?

Campbell Hausfeld is a brand that produces air compressors that are used to power pneumatic tools, inflate tires, and more. These compressors come in various sizes, designs, and models for different purposes.

What are the different types of Campbell Hausfeld Air Compressors?

Campbell Hausfeld produces several types of air compressors including, stationary, portable, oil-free, oil-lubricated, and pancake compressors.

What is the horsepower of Campbell Hausfeld Air Compressors?

Campbell Hausfeld Air Compressors come with different horsepower ratings, ranging from 1.3 HP to 7.5 HP, depending on the model and design.

What is the maximum pressure output of Campbell Hausfeld Air Compressors?

The maximum pressure output of Campbell Hausfeld Air Compressors varies from 90 PSI to 175 PSI depending on the model and design.

How do I maintain my Campbell Hausfeld Air Compressor?

You can maintain your Campbell Hausfeld Air Compressor by checking the oil level regularly, draining the air tank after use, replacing the air filter, and cleaning the compressor regularly.

Can I use my Campbell Hausfeld Air Compressor for painting?

Yes, you can use your Campbell Hausfeld Air Compressor for painting. However, you need to make sure that the compressor is clean and free from any oil or debris before use.

What is the warranty period for Campbell Hausfeld Air Compressors?

The warranty period for Campbell Hausfeld Air Compressors varies depending on the model and design, but it typically ranges from one to three years.

Can I run my Campbell Hausfeld Air Compressor on a generator?

Yes, you can run your Campbell Hausfeld Air Compressor on a generator. However, you need to make sure that the generator is powerful enough to handle the compressor’s electrical requirements.

What are the safety precautions when using Campbell Hausfeld Air Compressors?

Some safety precautions when using Campbell Hausfeld Air Compressors include wearing safety glasses, using ear protection, and avoiding pointing the air hose at yourself or others. Additionally, you should always read and follow the manufacturer’s instructions and safety guidelines.

[embeddoc url=”https://manualsdock.com/wp-content/uploads/2023/07/Campbell-Hausfeld-Air-Compressor.pdf” download=”all”]