![]()

ASSA ABLOY DL6010SM Swingdock Manual Minidock Leveler

About Assa Abloy

Assa Abloy affect every aspect of daily life, from dependable home security to cutting-edge biometric technology for corporations, governments, airports, hospitals, schools, and more.

They have operations in more than 70 countries, and our staff is well-versed in regional standards. They are experts in critical components of access, including mechanical and electronic locks, cylinders, keys, tags, security doors, and automated entrances. They are also developing and utilising new technology, such as trusted identities, mobile security, and biometrics. Whatever you require, you are in good hands since we remain at the forefront.

Economical manually operated dock leveler

The ASSA ABLOY DL6010SM Minidock is a manually operated dock leveler, specifically developed for operators of fleets of standardized vehicles with the same bed height.

The ASSA ABLOY DL6010SM Minidock is developed to be an easy to operate and economical solution in environments where standardized vehicles with the same bed height is used.

The ASSA ABLOY DL6010SM Minidock is equipped with a gas spring, making it easy for one person to operate – just lift and swing the platform. The ASSA ABLOY DL6010SM Minidock also meets the demands of most loading operations and fulfils all ergonomic requirements.

- Adapts to movements of vehicle bed

- The ASSA ABLOY DL6010SM Minidock design includes a limited, free-floating function, allowing the platform to adapt to the vertical movements of a vehicle bed during loading and unloading.

- Lip provides a smooth passage

- The lip of the Minidock is made of steel. The shape of the lip is extremely flat and the design of the rear connection to the dock edge is bump-free, resulting in a smooth passage between building and truck bed.

- Complete docking solution by ASSA ABLOY

- The ASSA ABLOY DL6010SM Minidock can be complemented with a dock shelter to get the advantages of a complete docking system.

Such solution improves the loading/unloading process and hence the working environment.

- The ASSA ABLOY DL6010SM Minidock can be complemented with a dock shelter to get the advantages of a complete docking system.

Technical Data

Handling rod for manual operation supported by a gas spring device

Dimensions

Installation modes / buffer options

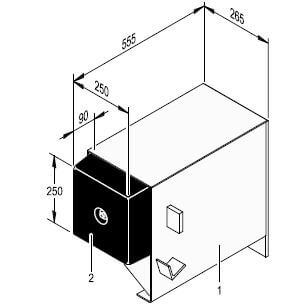

Ramp installation

- H x W x D = 500 x 265 x 555

- 1 steel support construction

- 2 buffer 250 x 250 x 90

- H x W x D = 500 x 265 x 555

- 1 steel support construction

- 2 buffer 500 x 250 x 90

Pit installation

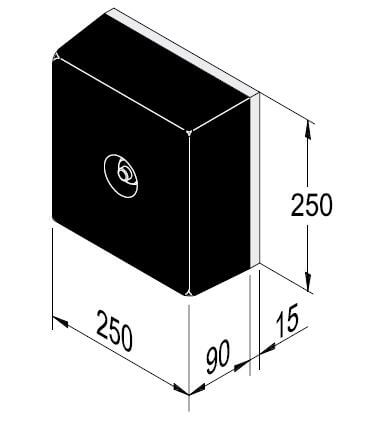

- H x W x D = 250 x 250 x 90

- 1 buffer 250 x 250 x 90

- 1 buffer 250 x 250 x 90

- H x W x D = 500 x 250 x 90

- 1 buffer 500 x 250 x 90

- 1 buffer 500 x 250 x 90

Surface

ASSA ABLOY as words and logo are trademarks belonging to the ASSA ABLOY Group http://assaabloyentrance.com

FAQs for ASSA ABLOY DL6010SM Swingdock Manual Minidock Leveler

What is the ASSA ABLOY DL6010SM’s size?

Dock levellers come in lengths ranging from 5 to 12 feet. The most common length, 8 feet, is appropriate for the majority of applications. A manual pallet truck’s typical maximum grade operation is 7%.

What kinds of dock levellers are there?

There are four types of loading dock levellers that are frequently used, and they are as follows:

Dock levelling machines

Dock levellers using hydraulics.

Dock levellers using air.

Dock Levelers, vertical.

How is a dock leveller maintained?

Clean the pit area first, then check and replace any worn-looking lip out devices (pins, lip cranks, links, chains, and shackles). Apply the right lubricants to the dock leveller in all necessary places. Examine each weatherseal (if one has been installed) and replace it if it is worn or damaged. Examine the dock bumpers.

A dock leveller can support how much weight?

Dock levellers typically have capacities ranging from 25,000 to 80,000 pounds. In this capacity range, dock leveller installations make up more than 90% of the total.

What is a dock leveler’s operating range?

While an Edge-of-Dock has an operating range of 5″ above and 5″ below the dock, a dock leveller has a conventional operating range of 12″ above and 12″ below the dock.

How can I strengthen my dock?

Gangways and ramps are the best options for stabilising a dock when it needs to be positioned farther from the coast to reach a particular desired water depth. The docks can move freely up and down gangways and ramps, but they need to attach to a fixed abutment.

Need electricity for hydraulic dock levellers?

The drawbacks of hydraulic dock levellers include the fact that, in contrast to mechanical dock levellers, they use power and are substantially more expensive to buy and install.

How do I safeguard my dock?

Marine fenders. Between a boat and a dock platform, fenders are buoyant cushions. They aid in avoiding unwanted dock contact and shield your yacht from harm from collisions with other boats. Fenders should always be kept on hand, even if your boat already has some fastened to the sides.

For more manuals by Assa Abloy, Visit:

For More Manuals Visit: