Renogy Rover 40 Amp 12V/24V DC Input MPPT Solar Charge Controller

About Renogy

Renogy is a provider of premium battery charging devices, LED lighting options, and solar panels. The company sells panels all around the world and is based in Chino, California.

Important Safety Instructions

Please save these instructions.

This manual contains important safety, installation, and operating instructions for the charge controller. The following symbols are used throughout the manual to indicate potentially dangerous conditions or important safety information.

- WARNING Indicates a potentially dangerous condition. Use extreme caution when performing this task

- CAUTION Indicates a critical procedure for the safe and proper operation of the controller

- NOTE Indicates a procedure or function that is important to the safe and proper operation of the controller

General Safety Information

- Read all of the instructions and cautions in the manual before beginning the installation.

- There are no serviceable parts for this controller.

- Do NOT disassemble or attempt to repair the controller.

- Do NOT allow water to enter the controller.

- Make sure all connections going into and from the controller are tight.

Charge Controller Safety

- NEVER connect the solar panel array to the controller without a battery. The battery must be connected first.

- Ensure input voltage does not exceed 100 VDC to prevent permanent damage. Use the Open Circuit Voltage (Voc) to make sure the voltage does not exceed this value when connecting panels.

Battery Safety

- Use only sealed lead-acid, flooded, gel, or lithium batteries which must be a deep cycle.

- Explosive battery gases may be present while charging. Be certain there is enough ventilation to release the gases.

- Be careful when working with large lead-acid batteries. Wear eye protection and have fresh water available in case there is contact with the battery acid.

- Carefully read battery manuals before operation.

- Do NOT let the positive (+) and negative (-) terminals of the battery touch each other.

- Recycle the battery when it is replaced.

- Over-charging and excessive gas precipitation may damage the battery plates and activate material shedding on them. Too high of an equalizing charge or too long of one may cause damage. Please carefully review the specific requirements of the battery used in the system.

- Equalization is carried out only for non-sealed / vented/ flooded / wet cell lead acid batteries.

- Do NOT equalize VRLA type AGM / Gel / Lithium cell batteries UNLESS permitted by the battery manufacturer.

- Default charging parameters in Li mode are programmed for a 12.8V Lithium Iron Phosphate (LFP) Battery only. Before using Rover to charge other types of lithium batteries, set the parameters according to the suggestions from the battery manufacturer.

- Please set the correct battery type the first time you use it.

WARNING

-

- Connect battery terminals to the charge controller BEFORE connecting the solar panel(s) to the charge controller. NEVER connect solar panels to the charge controller until the battery is connected.

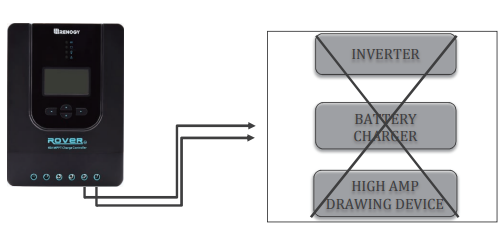

- Do NOT connect any inverters or battery chargers to the load terminal of the charge controller.

- Once equalization is active in the battery charging, it will not exit this stage unless there is adequate charging current from the solar panel. There should be NO load on the batteries when in the equalization charging stage

General Information

The Rover Series charge controllers are intelligent controllers suitable for various off-grid solar applications. It protects the battery from being over-charged by the solar modules and over-discharged by the loads. The controller features a smart tracking algorithm that maximizes the energy from the solar PV module(s) and charges the battery. At the same time, the low voltage disconnect function (LVD) will prevent the battery from over-discharging.

The Rover’s charging process has been optimized for long battery life and improved system performance. The comprehensive self-diagnostics and electronic protection functions can prevent damage from installation mistakes or system faults.

Key Features

- Automatically detect 12V or 24V DC system voltages

- Innovative MPPT technology with high tracking efficiency of up to 99% and peak conversion efficiency of 98%

- Deep cycle Sealed, Gel, Flooded, and Lithium (12.8V LFP) battery option ready

- Electronic protection: Overcharging, over-discharging, overload, and short circuit

- Reverse protection: Any combination of solar module and battery, without causing damage to any component Customizable charging voltages

- Charges over-discharged lithium batteries

- RS232 port to communicate with BT-1 Bluetooth module

MPPT Technology

The MPPT Charge Controller utilizes Maximum Power Point Tracking technology to extract maximum power from the solar module(s). The tracking algorithm is fully automatic and does not require user adjustment. MPPT technology will track the array’s maximum power point voltage (Vmp) as it varies with weather conditions, ensuring that the maximum power is harvested from the array throughout the day.

Current Boost

In many cases, the MPPT charge controller will “boost” up the current in the solar system. The current does not come out of thin air. Instead, the power generated by the solar panels is the same power that is transmitted into the battery bank. Power is the product of Voltage (V) x Amperage (A).

Therefore, assuming 100% efficiency:

- Power In = Power Out

- Volts In * Amps In = Volts out * Amps out

Although MPPT controllers are not 100% efficient, they are very close at about 92-95% efficient. Therefore, when the user has a solar system whose Vmp is greater than the battery bank voltage, then that potential difference is proportional to the current boost. The voltage generated at the solar module needs to be stepped down to a rate that could charge the battery in a stable fashion by which the amperage is boosted accordingly to the drop. It is entirely possible to have a solar module generate 8 amps going into the charge controller and likewise have the charge controller send 10 amps to the battery bank. This is the essence of the MPPT charge controllers and their advantage over traditional charge controllers. In traditional charge controllers, that stepped-down voltage amount is wasted because the controller algorithm can only dissipate it as heat. The following demonstrates a graphical point regarding the output of MPPT technology.

Limiting Effectiveness

Temperature is a huge enemy of solar modules. As the environmental temperature increases, the operating voltage (Vmp) is reduced and limits the power generation of the solar module. Despite the effectiveness of MPPT technology, the charging algorithm will possibly not have much to work with and therefore there is an inevitable decrease in performance. In this scenario, it would be preferred to have modules with higher nominal voltage, so that despite the drop in performance of the panel, the battery is still receiving a current boost because of the proportional drop in module voltage.

Four Charging Stages

The Rover MPPT charge controller has a 4-stage battery charging algorithm for rapid, efficient, and safe battery charging. They include Bulk Charge, Boost Charge, Float Charge, and Equalization.

Bulk Charge: This algorithm is used for day-to-day charging. It uses 100% of available solar power to recharge the battery and is equivalent to constant current. In this stage, the battery voltage has not yet reached constant voltage (Equalize or Boost), and the controller operates in constant current mode, delivering its maximum current to the batteries (MPPT Charging).

Constant Charging: When the battery reaches the constant voltage set point, the controller will start to operate in constant charging mode, where it is no longer MPPT charging. The current will drop gradually. This has two stages, equalize and boost and they are not carried out constantly in a full charge process to avoid too much gas precipitation or overheating of the battery.

-

- Ø Boost Charge: The Boost stage maintains a charge for 2 hours by default. The user can adjust the constant time and preset value of boost per their demand.

Float Charge: After the constant voltage stage, the controller will reduce the battery voltage to a float voltage set point. Once the battery is fully charged, there will be no more chemical reactions and all the charge current will turn into heat or gas. Because of this, The charge controller will reduce the voltage charge to a smaller quantity, while lightly charging the battery. The purpose of this is to offset the power consumption while maintaining a full battery storage capacity. If a load drawn from the battery exceeds the charge current, the controller will no longer be able to maintain the battery to a Float set point and the controller will end the float charge stage and refer back to bulk charging.

Equalization: This is carried out every 28 days of the month. It is intentional overcharging of the battery for a controlled period. Certain types of batteries benefit from periodic equalizing charges, which can stir the electrolyte, balance battery voltage, and complete chemical reactions. Equalizing charge increases the battery voltage, higher than the standard complement voltage, which gasifies the battery electrolyte.

WARNING Once equalization is active in the battery charging, it will not exit this stage unless there is adequate charging current from the solar panel. There should be NO load on the batteries when in the equalization charging stage.

WARNING Over-charging and excessive gas precipitation may damage the battery plates and activate material shedding on them. Too high of an equalizing charge or for too long may cause damage. Please carefully review the specific requirements of the battery used in the system.

WARNING Equalization may increase battery voltage to a level damaging to sensitive DC loads. Ensure that all load allowable input voltages are greater than the equalizing charging set point voltage.

Lithium Battery Activation

The Rover MPPT charge controller has a reactivation feature to awaken a sleeping lithium battery. The protection circuit of a lithium battery will typically turn the battery off and make it unusable if over-discharged. This can happen when storing a lithium battery pack in a discharged state for any length of time as self-discharge would gradually deplete the remaining charge. Without the wake-up feature to reactivate and recharge batteries, these batteries would become unserviceable and the packs would be discarded. The Rover will apply a small charge current to activate the protection circuit and if a correct cell voltage can be reached, it starts a normal charge.

CAUTION

When using the Rover to charge a 24V lithium battery bank, set the system voltage to 24V instead of auto recognition. If auto recognition is accidentally selected the Rover will allow you to change it to 24V when the lithium battery activates. In the activation interface press and hold the enter button to trigger the system voltage selector. To change the system voltage, press the Up or Down buttons then long press Enter to save the selected system voltage.

Additional Components

Additional components included in the package:

Remote Temperature Sensor:

This sensor measures the temperature of the battery and uses this data for very accurate temperature compensation. The sensor is supplied with a 9.8ft cable length that connects to the charge controller. Simply connect the cable and adhere to the sensor on top or the side of the battery to record the ambient temperature around the battery.

NOTE Do Not use this sensor when charging a lithium battery.

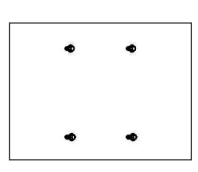

Mounting Brackets

These brackets can be used to mount the Rover charge controller on any flat surface. The screws to mount the brackets to the charge controller are included, screws to mount the charge controller to the surface are not included.

- Mounting Oval:7.66 x 4.70mm (0.30 x 0.18in)

Optional Components

Optional components that require a separate purchase:

Renogy BT-1 Bluetooth Module:

The BT-1 Bluetooth module is a great addition to any Renogy charge controller with an RS232 port and is used to pair charge controllers with the Renogy BT App. After pairing is done you can monitor your system and change parameters directly from your cell phone or tablet. No more wondering how your system is performing, now you can see the performance in real-time without the need to check the controller’s LCD.

Renogy DM-1 4G Data Module:

The DM-1 4G Module is capable of connecting to select Renogy charge controllers through an RS232 and is used to pair charge controllers with the Renogy 4G monitoring app. This app allows you to conveniently monitor your system and charge system parameters remotely from anywhere 4G LTE network service is available.

Identification of Parts

Key Parts

- PV LED Indicator

- Battery LED Indicator

- Load LED Indicator

- System Error LED Indicator

- LCD Screen

- Operating Keys

- Mounting Holes

- Remote Temperature Sensor Port (optional accessory)

- PV Terminals

- Battery Terminals

- Load Terminals

- RS-232 Port (optional accessory)

Installation

Recommended tools to have before installation:

Warning Connect battery terminal wires to the charge controller FIRST then connect the solar panel(s) to the charge controller. NEVER connect the solar panel to the charge controller before the battery.

Warning Do NOT connect any inverters or battery chargers into the LOAD TERMINAL of the charge controller.

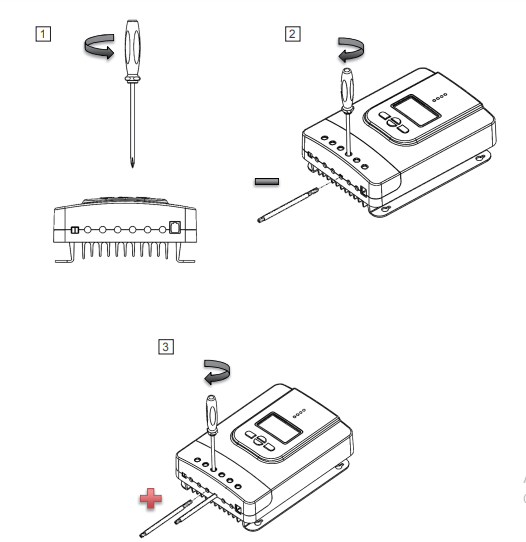

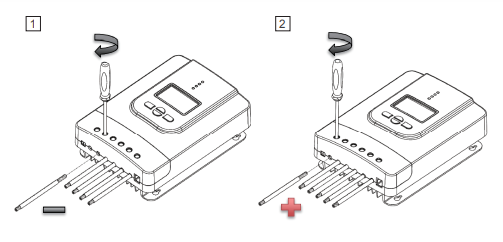

Caution Do not over-tighten the screw terminals. This could potentially break the piece that holds the wire to the charge controller.

Caution Refer to the technical specifications for max wire sizes on the controller and for the maximum amperage going through wires. You are now ready to begin connecting your battery to your charge controller.

Battery

Load (optional)

Solar Panels

Bluetooth Module communication (optional)

Temperature Sensor (optional, not polarity sensitive)

- Place the sensor close to the battery

Note Do NOT place the Temperature Sensor lug inside the battery cell.

Mounting Recommendations

WARNING

Never install the controller in a sealed enclosure with flooded batteries. Gas can accumulate and there is a risk of explosion.

- Choose Mounting Location—place the controller on a vertical surface protected from direct sunlight, high temperatures, and water. Make sure there is good ventilation.

- Check for Clearance—verify that there is sufficient room to run wires, as well as clearance above and below the controller for ventilation. The clearance should be at least 6 inches (150mm).

- Mark Holes

- Drill Holes

- Secure the charge controller.

Mounting Methods

The controller can be mounted using the existing mounting holes or using the included mounting brackets.

Using Mounting Hole

- Step 1. Measure the distance between each mounting hole on the Rover. Using that distance drill 4 screws onto desired surface.

- Step 2. Align the Rovers mounting holes with the screws

- Step 3. Verify all screw heads are inside the mounting holes. Release the controller and check if the mounting feels secure.

Using Mounting Brackets

- Step 1. Install the brackets using the provided components

- Step 2. Align the mounting brackets to the desired surface and use the appropriate screws to drill into the surface (screws not included)

- Step 3. Verify mounting is secure

Operation

Rover is very simple to use. Simply connect the batteries, and the controller will automatically determine the battery voltage. The controller comes equipped with an LCD screen and 4 buttons to maneuver through the menus.

LCD Indicators

Rover Protections

System Status Troubleshooting

Maintenance

WARNINGRisk of Electric Shock! Make sure that all power is turned off before touching the terminals on the charge controller.

For best controller performance, it is recommended that these tasks be performed from time to time.

- Check that the controller is mounted in a clean, dry, and ventilated area.

- Check the wiring going into the charge controller and make sure there is no wire damage or wear.

- Tighten all terminals and inspect any loose, broken, or burnt-up connections.

- Make sure LED readings are consistent. Take necessary corrective action.

- Check to make sure none of the terminals have any corrosion, insulation damage, high temperature, or any burnt/discoloration marks.

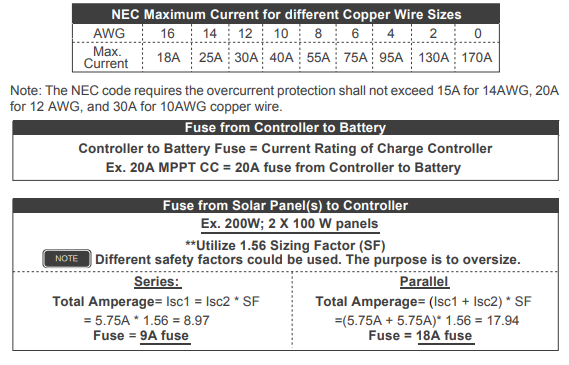

Fusing

Fusing is recommended in PV systems to provide a safety measure for connections going from panel to controller and controller to battery. Remember to always use the recommended wire gauge size based on the PV system and the controller.

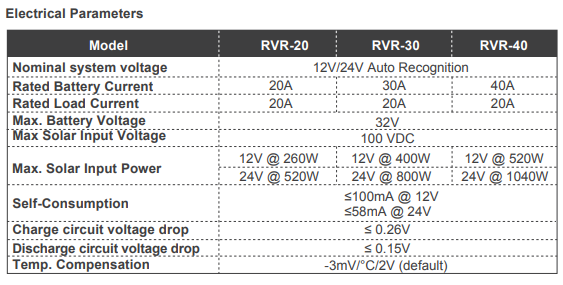

Technical Specifications

FCC Part 15

This equipment has been tested and found to comply with the limits for a class B digital device, under part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses, and can radiate radio frequency energy and if not installed and used by the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and the receiver.

- Connect the equipment to an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

- this device may not cause harmful interference, and

- this device must accept any interference received, including interference that may cause undesired operation.

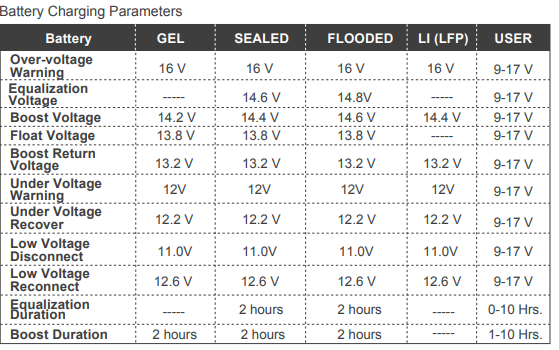

Battery Charging Parameters

- Battery charging parameters in USER mode can be programmed using the Renogy BT App.

- Default charging parameters in LI mode are programmed for a 12.8V LFP battery. Before using Rover to charge other types of lithium batteries, set the parameters according to the suggestions from the battery manufacturer.

- Parameters are multiplied by 2 for 24V systems.

Rover– Conversion Efficiency Curves

- Illumination Intensity: 1000W/ m2

- Temp 25℃

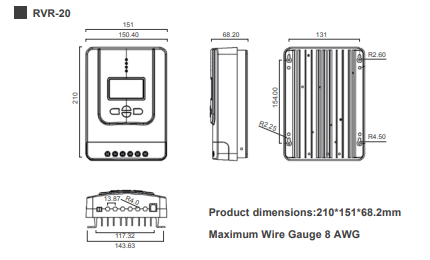

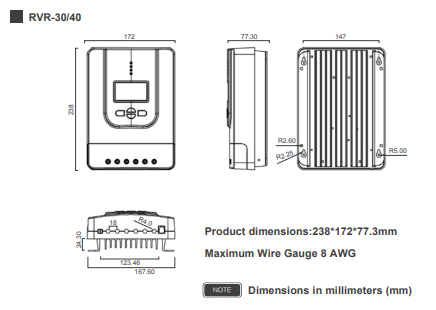

Dimensions

FAQS About Renogy Rover 40 Amp 12V/24V DC Input MPPT Solar Charge Controller

What is MPPT?

MPPT stands for Maximum Power Point Tracking. It is a technology used in solar charge controllers to optimize the power output from solar panels by adjusting the electrical operating point of the modules.

What is the input voltage range for the Renogy Rover 40 Amp MPPT Controller?

Check the product specifications for the exact input voltage range. It’s crucial to match the controller’s input range with the voltage of your solar panel array.

Can the Rover 40 Amp MPPT Controller be used for both 12V and 24V battery systems?

Many MPPT controllers are designed to work with both 12V and 24V battery systems. Verify this information in the product manual.

What is the maximum solar panel input for this controller?

Confirm the maximum solar panel input wattage and voltage supported by the charge controller. This ensures that your solar panels are within the controller’s specifications.

How is the Renogy Rover 40 Amp MPPT Controller installed?

Review the installation instructions provided by Renogy. This usually involves connecting the solar panels, battery, and load according to the specified wiring diagram.

What are the protections features of the charge controller?

Find out about the built-in protections, such as overcharging, over-discharging, short circuit, and overtemperature protection. These features help safeguard your solar power system.

Does it have a remote monitoring option?

Some MPPT controllers offer remote monitoring capabilities. Check if the Renogy Rover 40 Amp Controller can be monitored remotely and what accessories may be required.

Is there a warranty for the Renogy Rover 40 Amp MPPT Controller?

Verify the warranty period and terms provided by Renogy. This information is usually found in the product documentation.

Can the charge controller be used with different battery types?

Confirm if the charge controller supports various battery types, such as lead-acid, gel, or lithium-ion batteries.

How efficient is the Renogy Rover 40 Amp MPPT Controller?

Look for information on the controller’s efficiency under different conditions. MPPT controllers are designed to maximize efficiency in converting solar power to usable energy.

For more manuals by Renogy ManualsDock